First Line runs through some crucial modifications to the thermostat housing on popular PSA applications.

Despite the extensive durability testing that the VMs put the numerous components, designs and systems that are incorporated into their vehicles through, problems do occur and design faults are revealed during their day-to-day, real-world operation. This naturally means that over their production life, apparently identical models will actually differ in terms of the modified or redesigned components that are fitted, to allow the VMs to resolve the issues that come to light when the vehicles are in everyday use.

A great example of this can be seen on multiple PSA applications – Citroën C3, C4, DS3, Peugeot 207, 208, 2008, 308, 3008, 508, 5008, RCZ, Partner, BMW MINI – 1.4i/1.6i 2006 onwards – where there are known issues caused by the specification of the thermostat and thermostat housing installed during their original production. This led to an increasing number of premature failures, with many owners complaining of overheating-related problems and reporting symptoms such as an irregular temperature gauge, erratic engine running, radiator fan run-on or poor heater function. As a result, PSA has modified the design of the thermostat housing several times in an attempt to correct the issues.

The modified versions have several enhancements, including reinforced connections and a more robust structure to minimise the potential of warping or fracturing. The lower sensor has been moved to accommodate a new electronically operated thermostat, which replaces the wax version used in the original design. Technicians need to be aware that these modifications mean that there is a visual difference between the new and old designs. However, providing the factor has supplied what is specified in the First Line catalogue, rather than what ‘through experience’ they consider to be the ‘correct’ replacement, then garages can have complete confidence that it is correct for the application and therefore appropriate to install, even if it looks different.

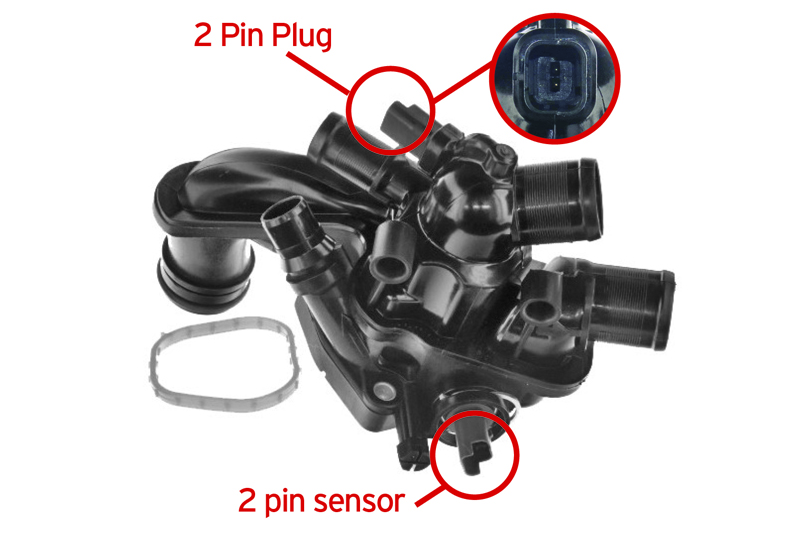

In particular, the references that have been re-specified include First Line part number FTK422. Originally, this had a single 4-pin sensor on top of the housing, but this has been modified by changing it to two, 2-pin sensors – one remaining at the top and the second being moved to the lower side. As this original single sensor has been split into two, a new wiring harness is required, which is only available from the OE supplier.

The OE design of the housing was then modified again, this time necessitated by the replacement of the wax thermostat by a new electronically controlled version, and to accommodate the change, the lower sensor was moved round to the back of the housing. Therefore, FTK422 was subsequently superseded by FTK454 following these modifications.

Other supersessions include FTK102 and FTK396, which have been superseded by FTK481 and FTK477 respectively. The housing for these two references already had the two, 2-pin sensors and therefore only underwent the thermostat modification and lower sensor relocation.

Despite these relatively small changes in the overall scheme of a vehicle, without prior knowledge, these differences can cause confusion for technicians tasked with undertaking service and repair work associated with these components.

However, according to the company, one of the main benefits of fitting First Line products is that technicians can be sure that the component they are installing follows the latest OE specification, whether it looks familiar or not. In order to follow best practice, First Line says that when replacing any of these thermostats/thermostat housings, it is advised that the engine ECU software is checked and reprogrammed before any components are replaced, to ensure it is set to reflect the latest version.