Graeme Ryder of Apec Braking explains the impact of the latest regulations for discs and drums.

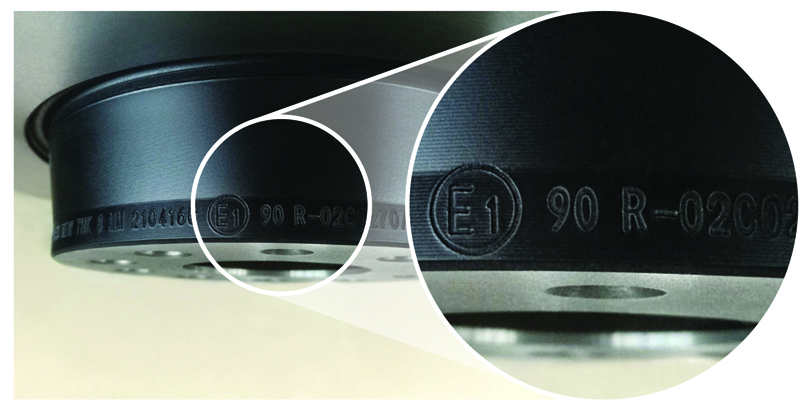

The ECE R90 regulations for brake pads and shoes were launched back in 1999, in order to define standards and establish an acceptable braking performance level for aftermarket parts. To deal with the threat posed to safety by cut-price, substandard parts, the extended R90 regulations for passenger car and van discs and drums came into force last November. Let’s recap on what they mean for you, your workshop and your customers.

R90 compares the physical and geometric properties, performance and integrity of aftermarket parts with the OE part fitted to the vehicle from new. The key parameters include chemical composition; mechanical properties; thermal fatigue; load and performance tests; friction and conformity; and production consistency. The aftermarket part must match the OE part to within a set percentage for all these criteria.

“R90 also checks the critical dimensions and balance of the disc or drum. If the parts are beyond acceptable tolerances, you could struggle to fit them or find your customers complaining about increased noise and uncomfortable judder.”

Better or worse than OE?

That tolerance limit means aftermarket discs and drums can theoretically perform better than the OE part. In reality, many of them may struggle to equal OE braking performance and, as a rule of thumb, the less you pay the poorer the performance is likely to be.

As we discovered when we recently commissioned a series of independent tests on aftermarket brake pads, some didn’t meet the R90 criteria – although the Apec pads equalled or, in some areas, exceeded OE standards.

So, do these R90 regulations for discs and drums really matter? Couldn’t you save yourself and your customer some money by not bothering about R90 conformity? Well yes, you might save money in the short term, but sooner or later you’re likely to be repaid with grief from a dissatisfied customer – especially if their brakes failed to perform in an emergency.

“R90 also checks the critical dimensions and balance of the disc or drum. If the parts are beyond acceptable tolerances, you could struggle to fit them or find your customers complaining about increased noise and uncomfortable judder.”

Know the risks

For example, the R90 tests check the chemical composition, microstructure and hardness of the disc or drum material. Failure to meet the R90 standards could mean not only rapid wear, but also the possibility of a disc or drum breaking up due to a flawed internal structure – with potentially lethal consequences.

Then there are the dynamic R90 tests, including thermal fatigue and braking load. Although mostly carried out in laboratories, these are tests with real world implications. They provide a clear indication of how well the disc or drum can withstand sudden or sustained harsh braking and continual everyday use, compared to the OE part. A substandard part might crack or shatter due to thermal overload, or simply be unable to stop the vehicle within the allowed distance compared to OE. At 70mph, that could amount to several car lengths.

Choose parts you can trust

The whole point of ECE R90 for discs and drums is to safeguard you and your customers against poor braking performance from counterfeit and substandard products. Although the recently introduced R90 regulations only apply to discs or drums fitted to a vehicle built on or after 1st November 2016, Apec discs and drums have been meeting these standards for several years. So, when you order Apec discs and drums for vehicles built before that date, you can be confident in their quality, materials and braking performance.

The whole point of ECE R90 for discs and drums is to safeguard you and your customers against poor braking performance from counterfeit and substandard products. Although the recently introduced R90 regulations only apply to discs or drums fitted to a vehicle built on or after 1st November 2016, Apec discs and drums have been meeting these standards for several years. So, when you order Apec discs and drums for vehicles built before that date, you can be confident in their quality, materials and braking performance.

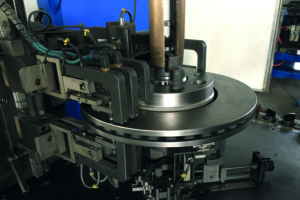

That’s borne out by the manufacturer’s guarantee, which covers Apec discs and drums (and all other Apec Braking components) for two years or 24,000 miles. And the company’s compliance with ECE R90 isn’t a one-off or achieved with specially prepared parts. Discs and drums are taken at random from the production line and subjected to every test in the R90 regulations. A failure would mean scrapping the entire batch, but because we don’t compromise on manufacturing quality, we don’t get failures.