When is an OE part modification not an OE modification? When it’s an OE part supplied by an alternative OE supplier, says Gates.

Guaranteed supplies

Instead of sourcing parts from a single parts manufacturer, OE manufacturers often commission a range of component designs from different suppliers in order to guarantee supply. For example, the OE tensioner for the timing belt drives on a wide range of 1.6L diesel engines – as fitted to the VW Polo, for example – are both supplied by Gates and Litens (this tensioner will also replace other tensioners in vehicles fitted to 1.6 and 2.0L engines throughout the VW Audi group).

Both tensioners are OE designs. They were both developed to be compatible with the drive systems in these vehicles. The tensioners perform the same tasks. They deliver equivalent performances. The key differences between the timing belt tensioners are that:

■ They do not look the same

■ The installation procedures are different

Installer perceptions

Mechanics who order Gates tensioners as part of a scheduled timing belt kit replacement have been taken by surprise if the vehicle has a Litens version. Similar reactions are to be expected among mechanics who have found a Gates tensioner when they were expecting to find the Litens alternative.

It is important to realise that, in each case, the mechanic has a tensioner that was designed specifically for the job.

Identification concerns

Take a careful look at Fig 1. This is the Double Eccentric tensioner supplied by Litens. Fig 2 is the OE tensioner designed and supplied for these engines by Gates. It is a Single Eccentric (off centre) design.

Note the locating tab in Fig 1. This is a major difference between the two components that raises significant concerns among many installers. The Gates design has no such tab.

‘If there is no locating tab, it can’t be installed’, is popular myth number one.

Replacement procedures

Many installers believe that the purpose of the tab is to lock the tensioner in place and prevent movement. In reality, the tab’s purpose is to locate the tensioner and prevent back plate rotation (left to right). If the back plate is unable to move, the tensioner could not work. In practice, it is vital that the back plate moves up and down, in the slot, as part of the installation procedure. The tab guides movement.

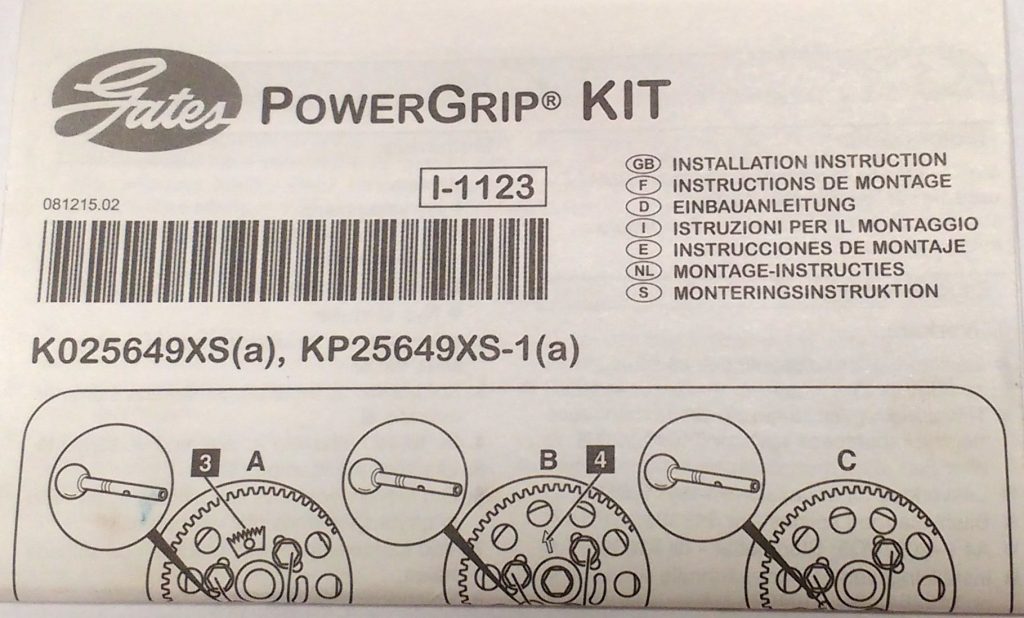

An essential part of the Litens installation procedure involves the use of a pin to lock the internal eccentric. With the tensioner inside the belt but still positioned outside the drive system, slack is needed to slip the belt over the pulleys. This is achieved by rotating the tensioner. Once in place, the pointer is aligned with the back plate by removing the pin and turning the adjuster clockwise.

In practice, it is faster and easier to install Gates tensioners on these applications. The Gates tensioners are mounted with an allen key in the 9 o’clock position. There is enough slack for the belt to fit easily around all of the pulleys. Once in position, the adjuster is turned anticlockwise, until the back plate and indicator are aligned.

Installer fears

Popular myth number two is that the procedure for installing Gates tensioners on these models is so straightforward that it must be wrong. Gates’ response is to include tech Tip No.12 for every appropriate model. Tech Tip No.12 identifies the differences between the two tensioners. Instructions for installing the tensioner are a standard inclusion with every box.