Josh Jones explains why technicians needn’t be intimidated by the rapid evolution of vehicle technology. However complex these new vehicles may appear, they still have to abide by the laws of physics.

As car technology changes rapidly, it’s good to know that the laws of physics do not. In the context of the automotive trade, the biggest threat we face in terms of sustainability is the advance of new technology in cars. In carrying out the simple case outlined below, I was reminded that the basic principles of testing don’t change as quickly as the technology, thankfully.

Luckily for us, no matter how complicated a car becomes to diagnose and repair, it will always have to obey the laws of physics. So, having a good grasp of the way electricity is used in a glow plug circuit, for example, gives you a fighting chance of eventually understanding the way it will be used to propel a transmission in the future (with the help of training of course). The principles are the same and that is to our advantage.

I investigated an EML illumination on a 2015 Audi A6 2.0 TDI Ultra recently. The only physical symptom exhibited was a slightly restricted performance. P0672 was retrieved from the ECU, which translated as a glow plug circuit fault on cylinder 2. Naturally, before replacing any glow plugs I wanted to confirm the issue was the plug itself and not any associated equipment. I attempted to use an amps probe attached to my scope to carry out a simple current profile comparison test on each of the four glow plugs. I like to use the current probe wherever possible as it is completely unobtrusive to the wiring and it’s very quick.

Unfortunately, checking the activation of the plugs on this particular vehicle (and plenty of other makes and models) is not as straight forward as turning on the key and analysing the way the plug consumes the current while it is supplied with 12V by a timer relay. Those times are long gone!

In this case, upon cycling the ignition, with the engine still cold, and the clamp connected to any of the plugs, there was no current flow to any of them to enable me to test the circuits simply. Even with the DTC deleted, the results were the same. It turned out that the way plugs are controlled is much more intelligent than them simply being activated for a period of time before every start. The symbol on the instrument panel that drivers know as the ‘glow plug lamp’ switched on and off every time I started the car but the illumination of the lamp did not correspond exactly to activation of the pre-heating system. Just like a coolant temperature gauge on most cars these days, the readout on the dash is not simply a direct readout.

In the same manner, with a modern cooling system, operating normally with the engine warmed up, the needle will sit bang in the middle of the gauge and stay right there, even though the actual temperature of the coolant is constantly adjusted by the ECU in response to engine load etc. The changes might be up to around 15˚C but the gauge never moves. It is there to provide reassurance to the driver primarily and will only move north if there is something really wrong. In a similar way, the pre-heat lamp on this vehicle illuminates to show the driver that the engine can prepare itself to start, to show the driver that the warning lamp itself is operational, and partly for familiarity, I would assume. Not as simple to test as older technology but much more dynamic and refined from the point of view of the driver.

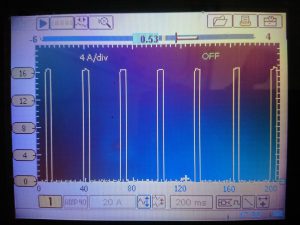

Anyway, in order to test the glow plug circuit on this car, I either needed to wait for the weather to get colder or carry out a functional test using a scan tool to activate the pre-heat system so, obviously, I chose the latter (see Fig 1).

The results of this test were no current flow through plug number two but good current flow through the other three. On further visual investigation, the connection at the plug itself for the offending circuit had partially come apart, causing a poor connection (see Fig 2) so there was no need to carry out a further test on the glow plug itself. After checking the connection for burn marks and reseating the connector, the current flow through the circuit matched the other plugs well, so I was satisfied no further investigation was needed. This was a simple job with no replacement parts required but it really brought home to me that although there have been massive advances in the operation of engine management in the last 20 years, the fundamentals are still the same in terms of what components are actually there to do. Had I not had the facility to carry out a function test in this case, provided I had my scope to be able to view the way the ECU controlled the pre heat circuit or even just a good old DVOM to carry out a volt drop check on the harness, I would have found the issue anyway.

I remember testing glow plugs on old straight diesel smokers during my apprenticeship when I had just started to get a feel for the relationship between voltage and current. Today, I find it comforting to see that in the engine bay of a snazzy Euro 6 Audi TDI there is still a glow plug that fundamentally operates in exactly the same way. I always use current before voltage in respect of test type because it is so quick and, more importantly, it always shows the circuit in operation or under load. Had I checked for supply voltage instead at the back of the glow plug connector, I would have seen a good supply and possibly not discovered the fault so easily.

It’s good to analyse the easy ones as they show us where we could go wrong with the hard ones! Over time the pattern has been that more and more engine systems have been fully ECU controlled but the components they control still carry out more or less the same task, so we can use our skill and experience to test them. As I stated at the beginning, the stuff we are working on these days is much more dynamic and refined than it ever has been, but it’s not a reason to be scared of analysing it manually.