Link rods are subjected to massive shock loading – more so on increasingly pot-holed roads. The safety of the vehicle depends on the smallest and most vulnerable part of the whole steering and suspension system.

The purpose of link rods

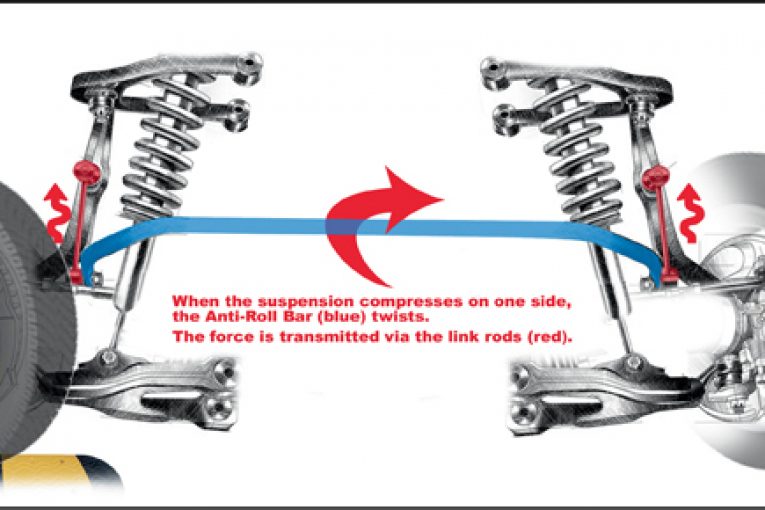

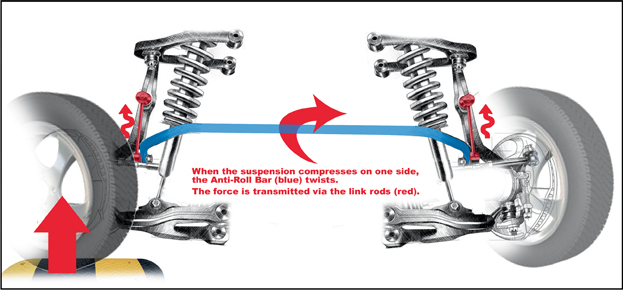

Link rods (or stabiliser links or anti-roll bar links or drop links) connect the left and right hand suspension components to either end of a common anti-roll bar made of spring steel which is like a torsion bar running across the car. The anti-roll bar only comes into play if the suspension on one side of the car moves but the other side does not.

For example, a car drives over a speed hump that goes the full width of the road. The suspension is compressed equally each side, the anti-roll bar simply pivots – it is not twisted and there is no strain on the link rods.

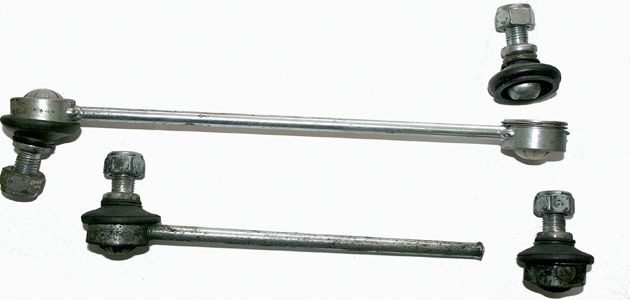

But if one wheel hits a speed hump and the other does not, one end of the anti-roll bar is raised – twisting the bar. The force needed to twist the bar is all transmitted through the link rods which are normally quite light metal or plastic rods with a ball joint on either or both ends.

Why do they fail?

Deteriorating road quality and speed humps are a big factor. If one wheel drops into a pothole the link rod is subjected to a massive shock loading. If this occurs in cold and wet conditions when materials used in the ball joint part of the rod are in a more brittle condition, then the ball joint may become vulnerable to water and grit ingress with the inevitable result – total failure.

The thicker the anti-roll bar the greater the impact. Sportier cars have thicker anti-roll bars to make them handle better, but this places increased stress on the link rods. Another vulnerable group are the current generation of SUVs which often have longer suspension travel than conventional cars, but the link rods are often no more heavily engineered.

Failure is a serious problem

Normally the ball joints or bushes at either end deteriorate and develop lost movement (play) which can be heard as a rattling or knocking noise. If this is ignored and the link rod actually breaks, the anti-roll bar becomes completely ineffective. The problems arise when the car is cornered hard, as it will roll much more than expected, causing serious and dangerous instability. It will, of course fail an MOT test.