Laser Tools provides a step-by-step guide on how to use its multi V-belt pulley alignment tool.

Multi V-belts are commonly used on the auxiliary drive systems on modern motor vehicles. It is important to ensure that all the pulleys are correctly aligned, to avoid premature belt wear and ensure maximum belt life. This new multi V-belt pulley alignment tool provides an easy visual check of pulley alignment.

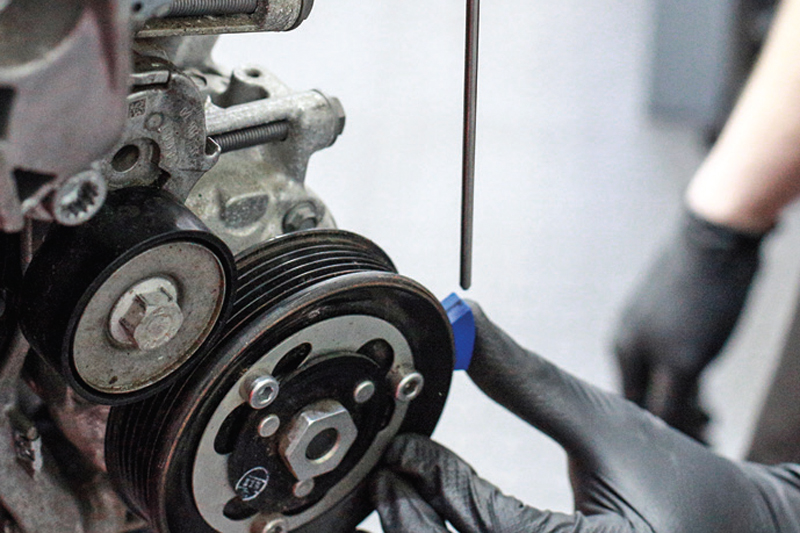

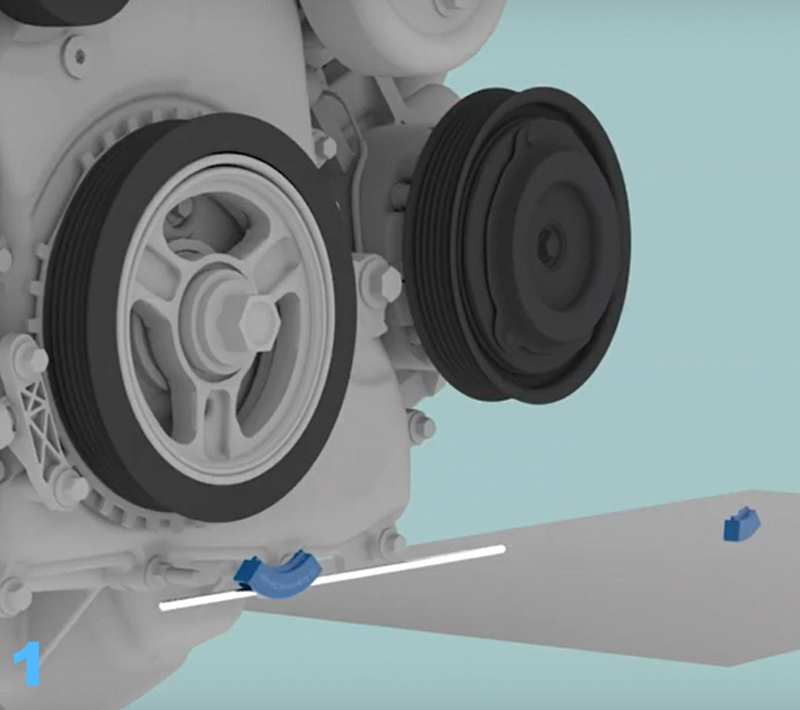

The tool comprises an alignment pointer and a marked alignment checking segment. These are designed to fit snugly into the V-grooves of the pulleys on the crankshaft, auxiliary components (alternator or air-con compressor, for example) and tensioners. When the tool is set up in equal positions on the two pulleys being checked (typically, two V-grooves in from the outer edge), looking down the straight, silver-steel alignment pointer gives an instant visual confirmation of correct (or otherwise) alignment.

The tool quickly picks up on common misalignment problems, such as parallel misalignment, angular misalignment, and pulley runout. Again, the pulley alignment tool gives a clear visual indication of the amount of misalignment or run-out.

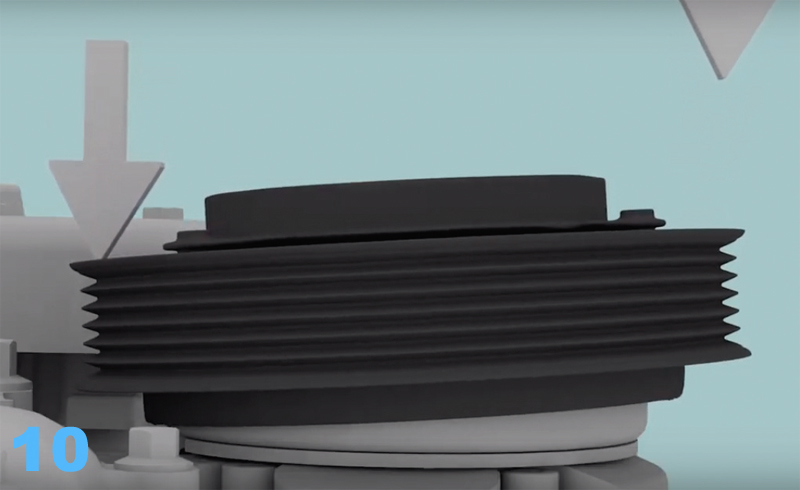

First, assemble the tool by pushing the steel alignment rod into the larger, plastic main segment. This is magnetised to fit snugly into the V-grooves of the pulley. Count two V-grooves in from the forward edge (Fig 1).

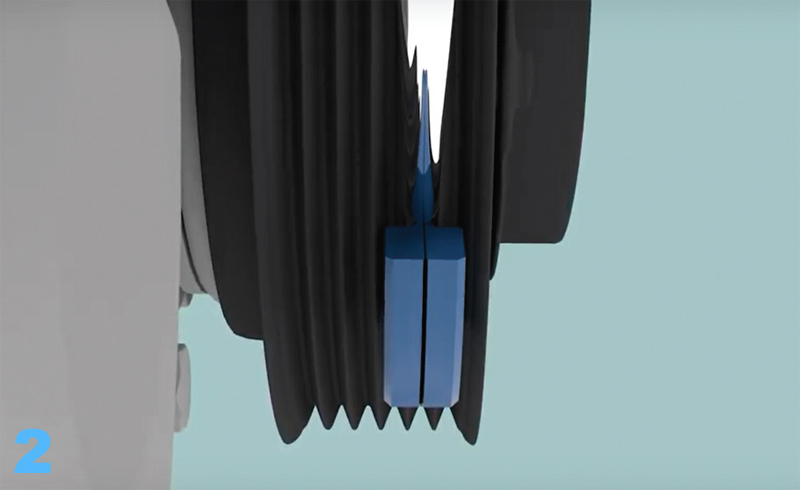

Now, place the smaller plastic alignment segment onto the pulley to be checked. Again, place it two V-grooves in. Look down the length of the steel alignment rod and check that it lines up with the markings on the alignment segment (Fig 2). In this instance, the pulleys are in alignment.

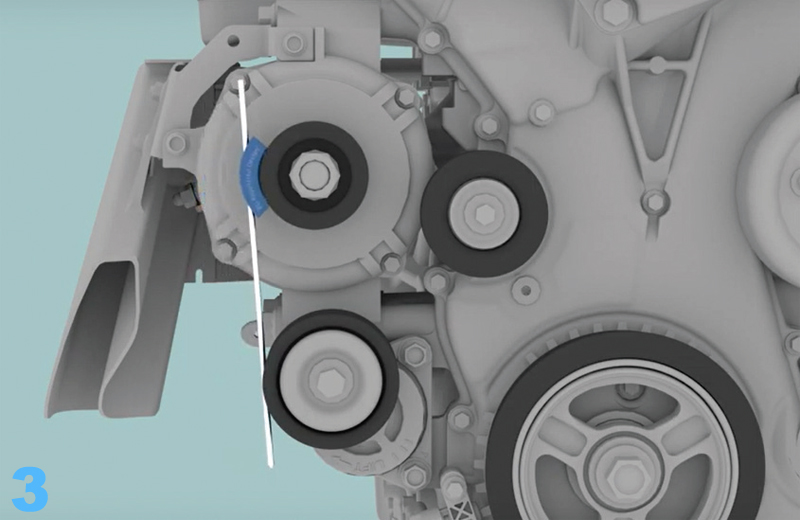

It’s always a good idea to double-check by moving the segments onto a different location on the pulley wheels (Fig 3). This follows the same procedure for checking auxiliary pulleys and tensioners; two grooves in and everything’s lining up.

Now, let’s have a look at some common misalignment problems.

Parallel misalignment

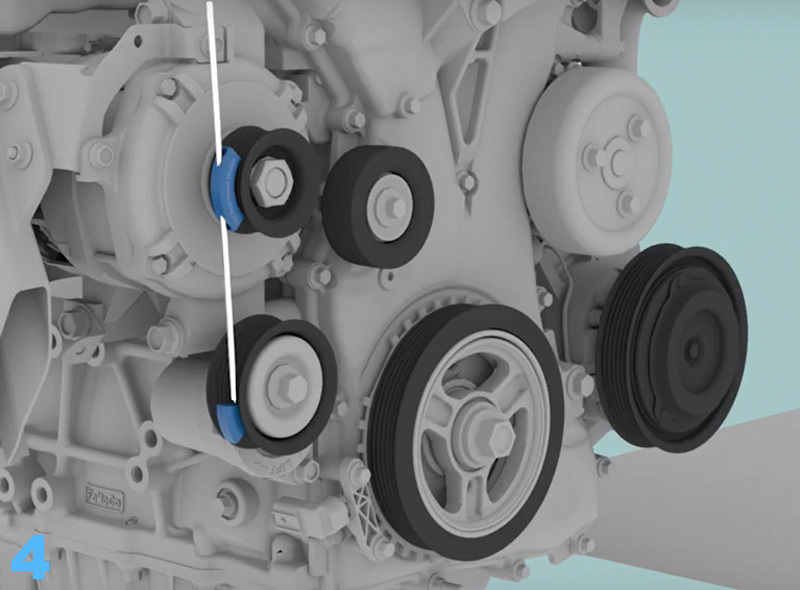

Parallel misalignment is where the pulley is quite straight, but it isn’t aligned correctly to the adjacent pulley (Fig 4).

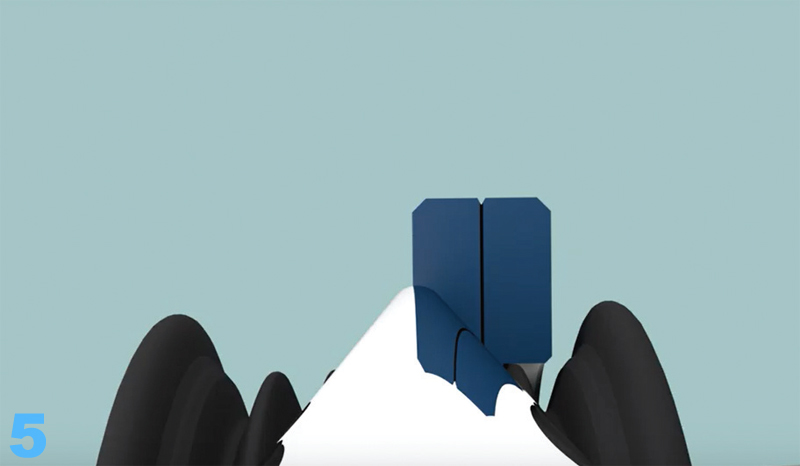

Place the segments two grooves in on each pulley and you can clearly see the misalignment. Double-check by positioning the segments on the different part of the pulleys and we get the same result (Fig 5).

Angular misalignment

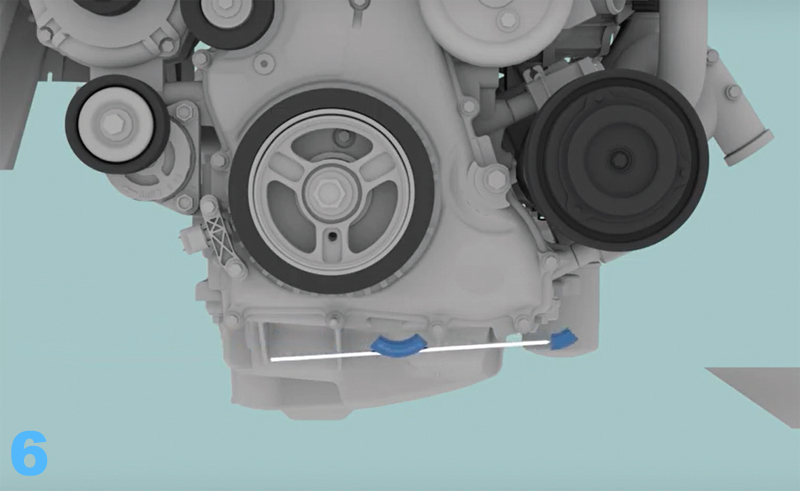

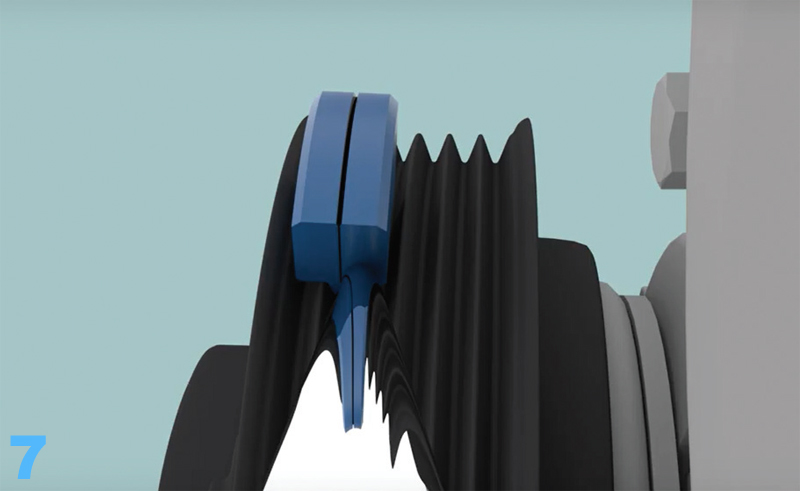

Angular misalignment can occur if the auxiliary component is not mounted correctly. Mount the tool segments as before, and as you can see (Fig 6 and 7), the tool clearly does not line up correctly.

Pulley runout

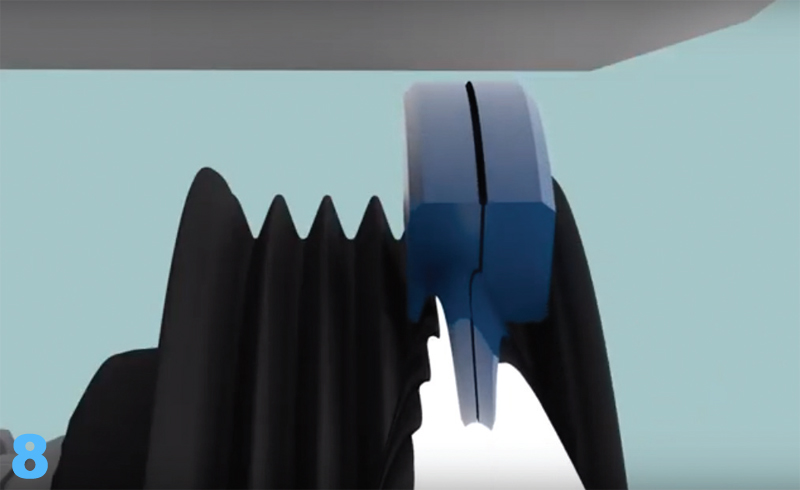

Pulley runout is when the angle of one pulley in relation to the other pulley is changing. This is usually due to a bent pulley shaft or a bent pulley. Again, the pulley alignment tool gives a clear visual indication of the amount of runout (Fig 8).

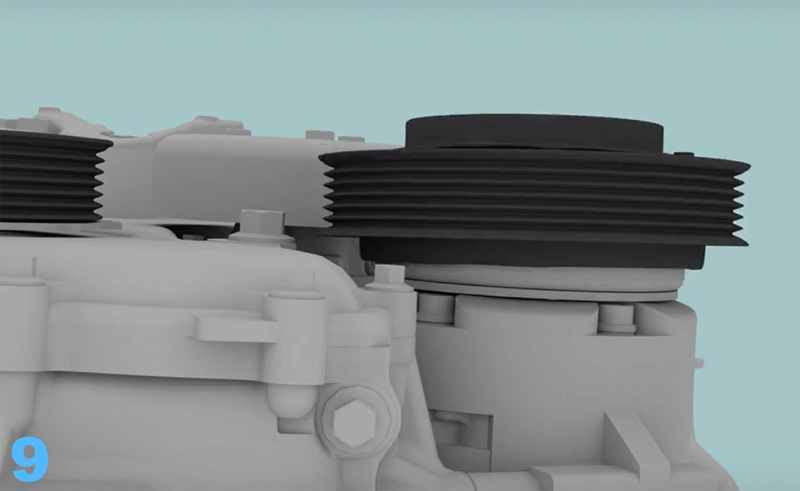

Pulley runout can also occur due to worn or damaged bearings, which manifests as excessive bearing float or play (Fig 9).

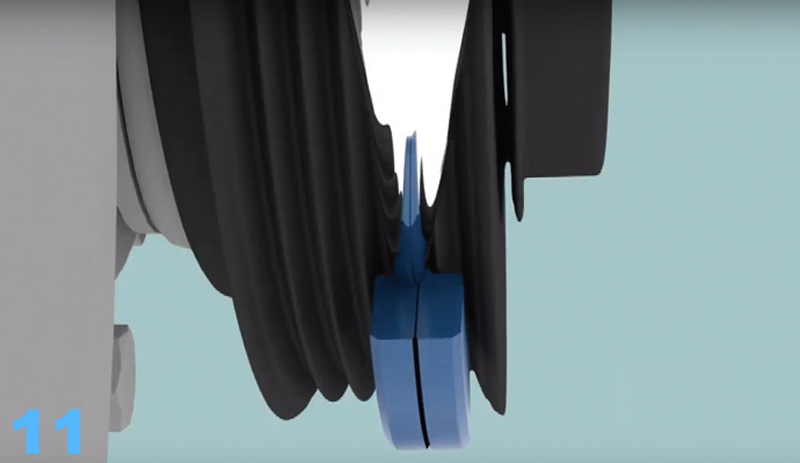

Maximum runout should be less than half a rib or V in 150mm. In the example below (Fig 10 and 11), it’s more than that.