Bosch discusses its complete Gasoline Direct Injection (GDI) proposition, which includes parts, diagnostics and training.

GDI is a key technology in the latest generation of gasoline vehicles, and is designed to deliver improved performance, increased economy, and enable the current trend in engine downsizing.

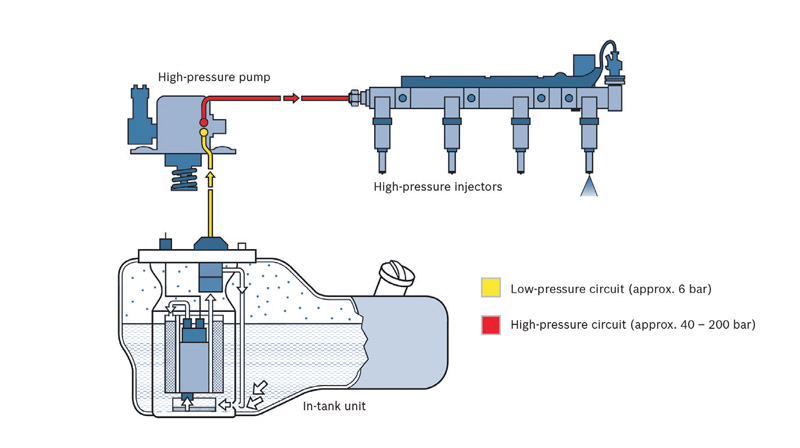

Modern GDI systems feature low pressure and high pressure circuits, with an electric fuel pump supplying a high pressure pump (HDP) with gasoline at around 6 bar. The HDP compresses it up to 200 bar and feeds it to the fuel rail, where high pressure injectors push precise quantities of perfectly mixed fuel directly into the combustion chamber.

Growing service market

By the end of 2019, there will be around four million cars on UK roads with direct injection gasoline engines, and this number is expected to double within a few years. To meet rapidly increasing demand, Bosch has created a GDI service solution for the automotive aftermarket, including components developed for racing teams, diagnostic solutions and industry training.

Workshop top tip

When installing spark plugs in GDI engines, the alignment of the side electrode in relation to the spray nozzle is critical. Installing the correct spark plug with the right tooling and torque is also crucial for optimum engine function.

Morten Jensen, Bosch Product Specialist for Gasoline, Europe North, said, “The GDI car parc is growing fast and, with our motorsport and OE credentials, independent workshops look to Bosch for parts, equipment and training. Unlike the previous generation of passenger car gasoline engines, which allowed for only an approximate mixture of gasoline and air, GDI enables an extremely precise blend, with optimised and variable spray timing under different load conditions.”

Bosch ESI[tronic] 2.0 and training

Today’s technicians expect more than just control unit diagnostics, whether for passenger cars or commercial vehicles. Intelligent troubleshooting and support for rapid repair and maintenance according to the manufacturer’s specifications are the new standard, and Bosch claims that these requirements are met with ESI[tronic] 2.0 Online.

The diagnostic software guides users through the process, and the Experience Based Repair (EBR) functionality provides instant access to known faults and reliable solutions.

In terms of training, Bosch’s VSG11 Gasoline Direct Injection System Diagnosis course promises to significantly improve technician efficiency. On successful completion, technicians will fully understand a typical Bosch GDI system, and be able to use serial diagnosis and oscilloscope data to quickly determine the required system or component repairs.

The course forms part of a comprehensive modern vehicle technology Training Programme, designed by Bosch specifically for independent workshops in the UK. For further details on the Gasoline Injection Systems training courses, and other courses in the Bosch range, click here.

Mark Heard, Bosch Marketing Manager for Europe North, said, “With the fastgrowing GDI vehicle parc, independent garages investing in the right training and equipment are set to make healthy profits and win business. Our ESI[tronic] platform includes detailed service instructions for GDI components, while our KTS tools just keep getting better.”