In this troubleshooting guide, Steve Carter looks at three vehicles from three different manufacturers, all with their own unique problems.

A sluggish Volvo

The first vehicle was a 2000 Volvo S40 1.6L 16 valve. The particular problem with this vehicle was its frequent, but random, inability to pull away from a standstill. This was not a transmission or clutch problem, but instead appeared to be the inability of the engine to develop sufficient torque from idle speed. Even applying a significant amount of throttle still made pulling away problematic, and as I mentioned previously, this problem was not continuous.

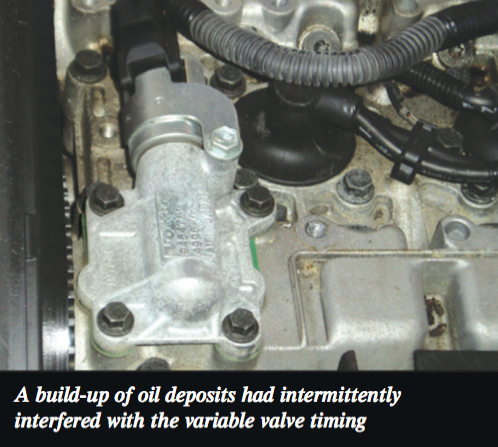

This particular engine is equipped with the EMS 2000 engine management system and does not incorporate fly-by-wire, so no throttle body adaption was available. Any idle adjustment is by means of a small grub screw. However, most of the time the idle speed appeared to be within specification. As you can see in the photograph to the right, this engine is equipped with continuous variable valve timing. The camshaft actuator receives its instructions from the engine ECM, which causes the actuator to channel engine oil under pressure, to alter the camshaft’s position, creating continuous variable valve timing.

On closer inspection of the actuator, significant amounts of solidified engine oil deposits could be seen in the galleries within the actuator. These deposits were cleaned out with a degreasing agent, and the problem was resolved.

A Polo with intermittent ABS

The next vehicle, a 2004 VW Polo 1.4, was brought in for its annual service and pre-NCT inspection. During the service, it was noted that the ABS warning lamp was on. Reading the fault code from the ABS ECM, it merely stated that the ABS pump had failed. This is a very expensive component to replace, and pointless if not necessary.

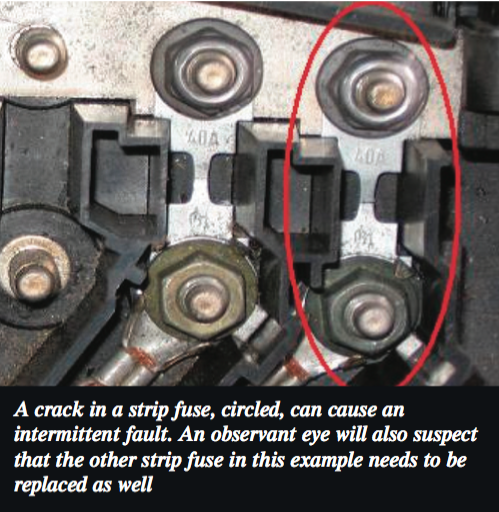

While obtaining the necessary pin data information, we checked the earth and battery positive supply to the ABS module. While carrying out these checks it was possible on one or two occasions to regain one of the positive battery supplies that had been lost. This coincided with leaning across the vehicle battery. It is relatively well-known that some of this vehicle’s fuses are housed within the plastic battery cover and that these fuses are just thin metal strips between two

bolt fixings. A blown fuse can be seen very clearly, but in our case the fuse had actually cracked and looked more like a scratch than a defective fuse. The fuse was replaced and the ABS was completely functional again.

A congested Citroen FAP

The next dilemma was a Citroen C8 2.2HDi FAP. The car had been bought at auction and was being prepared for resale when an anti- pollution fault came up on the dash. Unfortunately, the EOBD reader would not reveal sufficient information about this fault, or where to go next in fixing the vehicle.

With the appropriate level of diagnostics, it was possible to view the fault codes in more detail. The first fault related to the overloading of the particulate filter, the second being that the pressure differential sensor was too high on engine start-up. The first fault code is fairly straightforward – the vehicle had covered 58,000 miles and had a counter reading of 98g of soot residue within the DPF,

meaning it had reached its design limits and needed replacing. As a consequence of this, the Eolys tank was nearly empty and required refilling with the appropriate Eolys (remember that there are two types).

The second fault was more interesting, as it indicated excessive backpressure within the now clogged particulate trap before the engine was even running. Viewing the serial live data, it showed a backpressure differential of 993mb with the engine off.

The pressure differential sensors were located close to the DPF itself and with a heavily clogged filter it is possible for soot particles to become lodged within the sensor and cause incorrect pressure differential readings. Naturally, the engine’s ECM has to reduce engine performance in order not to generate high levels of backpressure, which would damage the turbo.

However, its plausibility routine had determined we had excessive backpressure without the engine running.