Champion provides an insight into its forensic approach to producing wiper blades.

Most drivers pay little attention to their windscreen wipers until they start causing problems. Soon enough, they fail to clear the screen fully, and then they start leaving long smears and streaks, not to mention the noisy creaking and juddering. It quickly becomes apparent just how effectively they did their job when new.

The choice of replacement wiper blades can be bewildering, with products for most cars available at a wide range of prices. The challenge for the consumer is to establish whether a higher price buys a better product, or just better packaging.

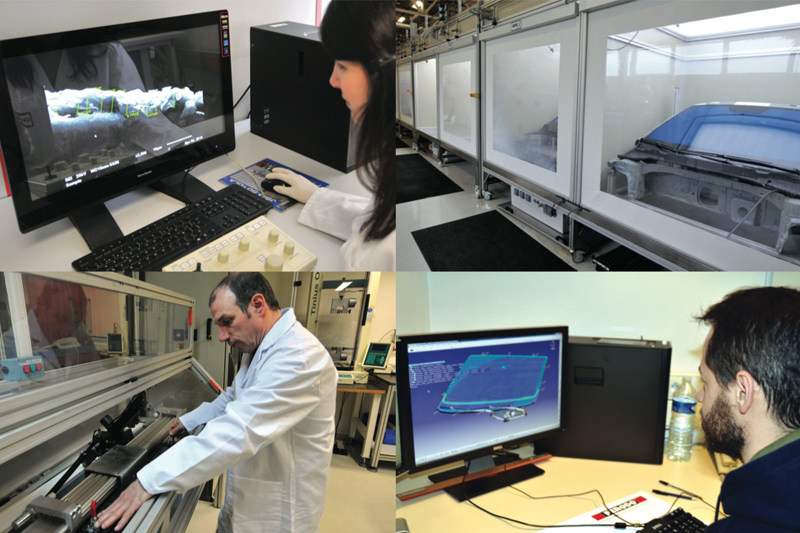

It may come as a surprise to discover the level of design and development that Champion, Federal-Mogul Motorparts’ wiper brand, puts into its wiper blades at its extensive R&D and testing facility in Aubange, Belgium. Before approving a new design for release to the market, the company carries out between 20 and 30 different tests.

The company currently produces wiper blades for some of the world’s biggest vehicle manufacturers, including VW, BMW, PSA, GM, Tesla, Fiat, Seat, Skoda, Bentley and Audi. All of its OE customers demand high- quality products – a standard that is reflected in the amount of testing carried out. The same OE-quality products are then distributed through the aftermarket under the Champion Aerovantage range, with the only change being to the multi-vehicle connector.

The rubber materials used in wipers are tested for resistance to Ozone and a variety of common chemicals, such as those found in de-icer, screenwash and carwash treatments. The staining test checks for chemicals leeching out of the rubber, while an ultra-violet resistance test identifies any tendency towards discolouration under exposure to sunlight. Once the materials are proven, Champion tests the wiper mechanically, as a complete product, to confirm its durability. Requirements vary between car manufacturers but can be up to 500,000 cycles, which equates to five years of use in many markets.

Torque tests determine the blade’s resistance to tearing, which may occur when a wiper is frozen onto the screen on a cold morning. Repeatedly lifting the arm and allowing it to fly back, at a range of temperatures, simulates the action of a customer returning the blades after cleaning the screen.

The effect of impact against compacted snow at the sides of the windscreen is reproduced by using blocks fixed in place, just within the limits of wiper travel and then continuously operating the wipers for 25 hours. Even the effects of mishandling are considered, using a random drop test that mimics a customer letting a blade fall from its packaging to the ground.

Once the mechanical durability has been validated, wiping performance tests are carried out at room temperature and between limits of 70 and -30°C. The wipers are tested at these extremes in order to guard against wiper damage when activated on a frozen screen, or on a day with ambient temperatures between 30 and 35°C, when the windscreen can reach temperatures of 50- 60°C in direct sunlight.

Wiping performance is evaluated after 72 hours ‘soaking’ at each test temperature. All wiper blades are subject to Champion’s performance standards for wiping quality, smear and judder. According to Rene Masson, Federal-Mogul Motorparts’ Global Director of Engineering and R/D for Wipers and Aubange Plant Manager, prolonged exposure to direct sun is the most damaging condition for wiper blades: “Cars parked each day in the shade can expect two or three times the life from their blades, compared to cars parked in the sun,” he states.

This also explains why sales of replacement wiper blades peak in September and October. Masson continues: “After the hot summer has damaged the blades, the arrival of poor weather such as fog and rain triggers the use of wipers again and drivers discover they need replacements”.

Up to this point, the tests have all been generic and independent of any particular application. The next step is to confirm the initial wipe performance and behaviour up to maximum speed on virtually every car in the market – no small undertaking.

“All wiper blades are subject to Champion’s performance standards for wiping quality, smear and judder.”“We make extensive use of rental cars and have access to a nearby test track with a 3km straight, which allows us to test at speeds of up to 200kph,” explains Masson. “For higher speeds, up to 240kph, we use a wind tunnel.”

Wiper blades, like many automotive components, are subject to changing trends. Over the last few years, the two most evident trends relate to aesthetics and noise. Car manufacturers want the wipers to be invisible when parked, and to reduce the driver’s ‘blind spot’ when operating. This has led to a trend away from bulky shapes fitted with spoilers to create downforce, towards a slimmer, flatter blade that creates its own downforce. Noise reduction throughout the modern vehicle has led to higher expectations for wiper refinement, with any juddering or squeaking completely unacceptable.

Champion has drawn on its long experience in the techniques required to meet these challenges. The company even works closely with the suppliers of windscreens to ensure that the shapes of both screen and blade, and any coatings used, are fully compatible with one another.

Masson believes the level of development and testing that goes into its wiper blades supports the claim by Champion that it provides the aftermarket with genuine OE- quality replacement parts. “They are made to the same design, from the same materials, and on the same production lines as the originals,” he says. “This means they provide the same quality, performance and life. The only difference is some standardisation of the mounting features, to standardise their application across several models and reduce stocking complexity for the distributor.”