Rotronics is reminding PMM readers that when it comes to passenger car batteries, testing can open the door to an easy win.

The recent Motor Ombudsman’s annual service and repair sector survey highlighted the main challenges workshops are set to face in 2024. Increased day to day running costs, recruitment and more expensive parts were all cited as issues together with customers putting off routine maintenance as well as essential repairs as the effects of the cost of living crisis continue to bite.

With a need to balance additional costs and profitability against possibly reduced footfall, customer retention is going to be a critical factor. Maximising revenue per customer is an increasingly important aspect and an easy win exists by offering battery service – testing, charging, and replacing batteries where necessary.

This of course is not new, and plenty has been written about the value of testing batteries. It’s unlikely any workshop does not possess a battery tester of some description. Despite this though a recent survey undertaken by Rotronics indicated that almost half of workshops do not routinely test batteries as part of a vehicle service.

Three steps to success

When it comes to battery testing, there are three issues to address if workshops are to maximise revenues and customer trust.

- Make testing part of the service process.

The tester is a workshop tool that should be as visible as a socket set and not kept in a drawer deployed only in emergencies. Bring it to the front of the workshop and adjust the service routine to include it. Once the routine is established our research shows the benefits will flow. - Use up to date equipment that provides reliable, consistent results.

A quick google search on ‘12V battery tester’ will reveal pages and pages of possibilities and prices. How to choose?We are biased of course, but choosing equipment from suppliers that work with the vehicle manufacturers for their – increasingly complex – battery needs is a good start. They demand ease of use, consistent results, robustness, and good technical back up service. Why settle for less? - Engage the customer with results of the test and any recommendations.

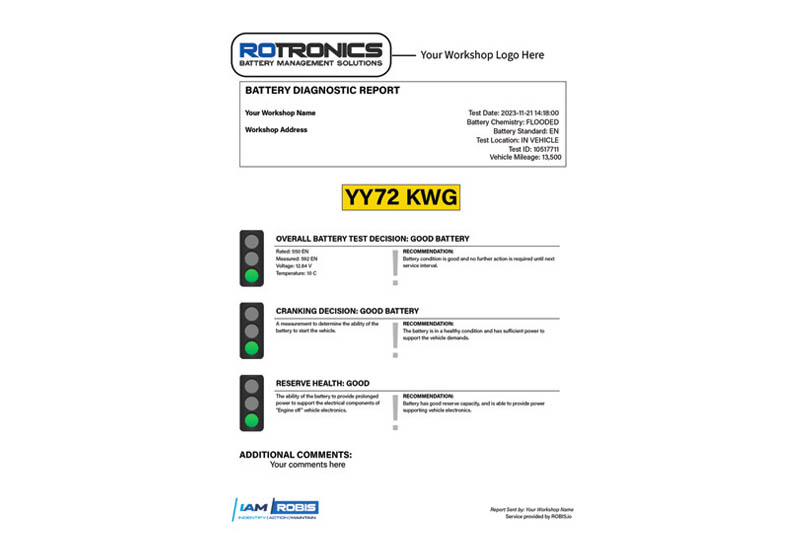

It’s vital to share test results with the customer. It can build trust and may lead to an additional revenue opportunity. Unfortunately, communicating results has not been easy. While some testers can come with printout facilities it’s still not plain sailing. The information is not presented in a clear to understand way and if the ‘till roll’ runs out and there is no more paper to hand the potential to engage is gone. Fortunately, there is another way…

Reliable tester

The latest CPX900 tester from Midtronics is easy to use, compatible with all 12V lead acid starter batteries including EFB and features Wi-Fi communication. That means that it is compatible with ROBIS – Rotronics own reporting system that for the first time allows you to share an easy to understand battery condition report to your customer. Using a ‘traffic light’ system ROBIS explains the key measurements in symbols and language everyone can understand and provides reassurance that a thorough test has been undertaken and that the results can, if necessary, be actioned easily.