Here, Nissens stresses the importance of servicing the air conditioning system.

To provide customers with the level of service they rightfully expect of a competent workshop requires the vehicle’s air conditioning system to be thoroughly assessed to ensure it is operating to its full efficiency, maximising its working life.

“One of the key assessments to ensure the A/C system’s reliability and effectiveness is the purity of the oil/refrigerant mixture,” explains Nissens Automotive’s Marketing Manager, Jan Zieleskiewicz. “So, rather than just offering to ‘top up the gas’ as the weather improves, it is sensible for workshops to periodically perform a system inspection and, among other checks, this should include a cleanliness inspection of the loop.

“The A/C circuit’s inner condition can tell a lot about potential problems within the system and deterioration of the medium mixture provides an excellent indication when making this assessment. Furthermore, the only way to determine the correct lubricant quantity in the system, as well as to secure the purity needed for its proper operation, is by flushing out the old mixture and replenishing it with fresh oil and refrigerant. Additionally, whenever replacing one of the system’s key components, such as a condenser or compressor, flushing is crucial to ensure a complete and effective repair.”

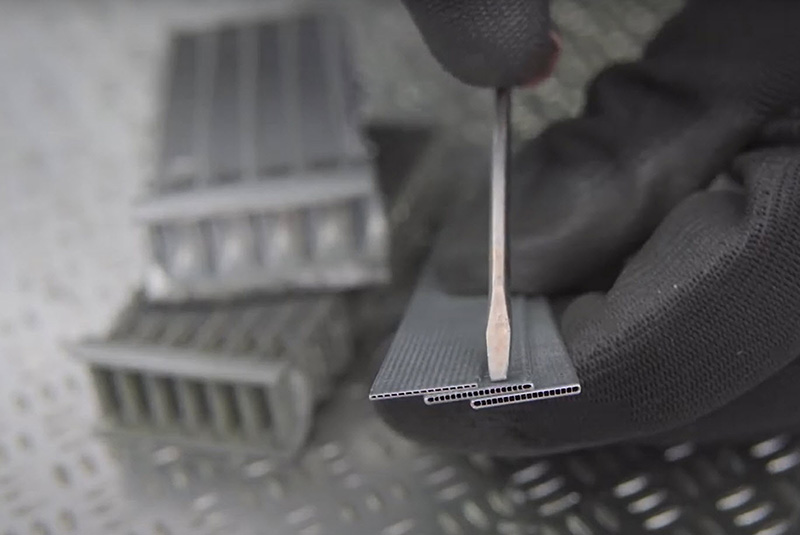

The refrigerant and lubricant necessary for the A/C system’s vital operation can get contaminated by substances such as moisture, particle formation due to uncontrolled chemical reactions, or careless use of additives including UV dye or leak-stop agents. These can easily cause clogs in the narrow channels within the system, leading to consequential severe failures, so flushing the system is vital, but how’s it done?

Nissens Automotive is widely respected in the independent aftermarket throughout Europe, not only for the premium quality replacement components it supplies, but for the technical support and advice it provides to the technicians that are responsible for carrying out automotive service and repair. So, it is highly qualified to answer this important question.

“There are three recommended ways to flush the A/C system, but there also some basic rules that have to be observed to do it successfully,” says Zieleskiewicz.

“First, irrespective of whether the A/C compressor is being replaced, it must be separated or bypassed when the flushing process is carried out, likewise the system’s expansion devices, such as the orifice tube or expansion valve, and the receiver drier or ‘desiccant’ should be removed and replaced after flushing. It’s also worth pointing out that parallel-flow, thin and micro-tube condensers, as well as evaporators, cannot be flushed effectively and should be replaced or back flushed whenever serious contaminants have impaired the system or following a previous compressor seizure.

“When it comes to the flushing, the preferred method will largely depend on the garage equipment and extra tools that the workshop has access to, but it must be effective and should not harm the system, which might be the case if an improper method was to be followed.

“Also bear in mind that, with whichever method, cleaning agent residues must be completely removed after flushing and the A/C loop must always be thoroughly dried, preferably by means of nitrogen and a longprocess vacuum.”

Method One:

Using a dedicated flushing detergent

Based upon circulating the detergent throughout the loop and injecting it directly from a pressure container or distributing it by a special flushing machine, this method dissolves all sorts of particles, sludge, stubborn soil, and residues.

Tip: This method can easily combine with highly pressurised nitrogen to ‘push’ the flushing agent through the ducts, but ideally, the loop segments should be flushed separately. This method has proven effectiveness against stubborn soiling and, besides facilitating the impact of the flushing agent, the nitrogen is very effective at moisture removal.

Method Two:

Refrigerant and filling station

This option uses the R134A/R1234yf refrigerant circulated around the A/C loop by the means of an A/C filling station. However, the filling station must be equipped with a flushing function, specially designed filters and a container to catch the contaminants. This method is good at cleaning loose particles, but isn’t very effective at rinsing our serious sludge and soils.

Method Three:

Refrigerant directly from bottle

This again uses the R134A/R1234yf refrigerant as the cleansing agent, but relies upon the adapter set and hoses having a tight leak-free connection. The refrigerant is circulated through the loop by heating up the bottle, but an additional bottle for contaminated gas must also be prepared. This method has the advantage that it does not require any additional agents or an AC filling machine, and is effective at cleaning loose particles, but isn’t very effective for rinsing serious sludge and soils.

“Once the AC system is properly flushed, and all of the necessary components have been replaced,” Zieleskiewicz continues, “technicians can proceed to inspect the system to ensure the joints are tight and there are no leaks, and then charge the system using the vehicle manufacturer’s prescribed specification and quantity of refrigerant and lubricant.

“As well as this flushing guide, that can be found here, we also have a wide range of additional technical resources at the disposal of professional technicians, which can be accessed via our comprehensive support portal.”