PMM finds out from Blue Print what the potential threats are to the fuel system if there is not a suitable filtration solution in place.

Filtration solution

Advancements in filter technology are a direct response to changes in engine technology. Modern petrol and diesel fuel systems contain the most accurately engineered components in an engine, manufactured to incredible tolerances of less than two microns and put under enormous loads. Fuel not only burns to make power, but in the case of a diesel engine, it also lubricates moving parts in the high-pressure fuel pump and injectors. Therefore, the fuel has to be clean.

Impurities in the fuel

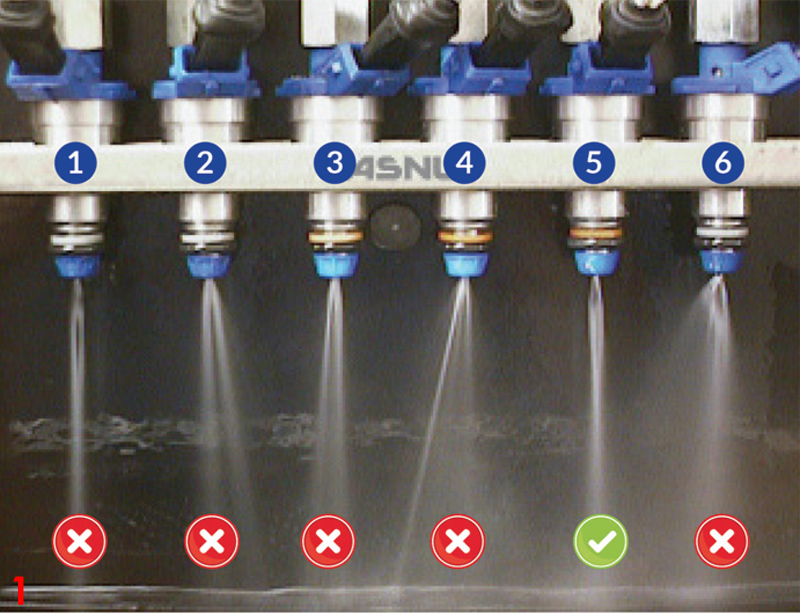

Unfortunately, impurities from service station refills and corrosion in metal fuel tanks are ever-present and can ruin a modern fuel system. Even the smallest particles can cause damage to an injector pintle causing spray pattern distortion. A correct spray pattern can be seen on the fifth injector in Fig 1; however, the remaining injectors are all displaying incorrect spray patterns.

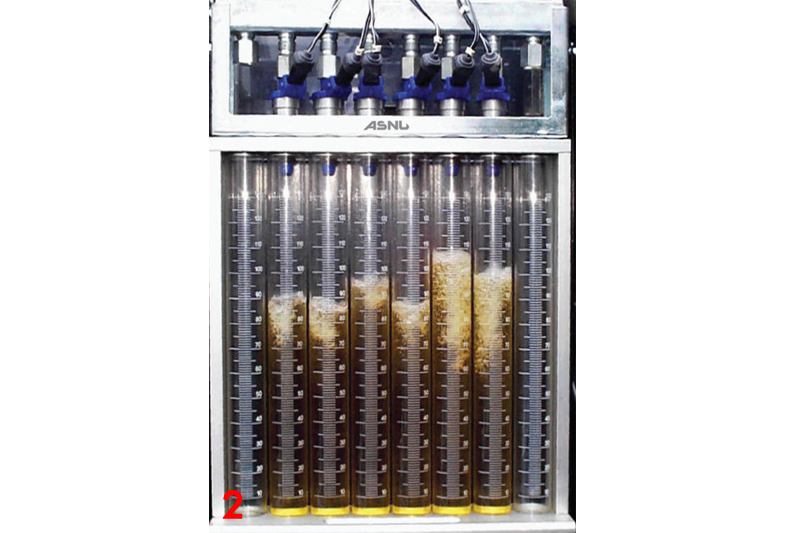

Fig 2 shows the result where the fifth tube has received the correct amount of fuel allowing the engine to run as intended. However, the remaining tubes have received less fuel than required, which in turn affects combustion efficiency, fuel consumption, idle stability and emissions.

Water contamination and separation

Whilst both petrol and diesel fuels need thorough filtering against abrasive contaminants, diesel has additional filtration requirements. Water molecules found in diesel fuel systems are a problem. Condensation takes place in the tank and the fuel can hold molecules of water in suspension or in emulsion. Without the correct filtration, water can corrode the components that make up the pump and injectors in the fuel system.

Blue Print diesel fuel filters use a hydrophobic coalescing material which allows fuel to pass through but retains the water. The separated water forms droplets that collect at the bottom of the filter canister, where they can be drained periodically as part of important routine maintenance.

Top tip: Over the last year, many cars will have been standing unused for long periods or only used for short journeys. It is therefore highly recommended that the fuel filter is changed as a precautionary measure. This is especially true for diesel vehicles where the fuel has not been circulating around the fuel system.

Fighting the fungus

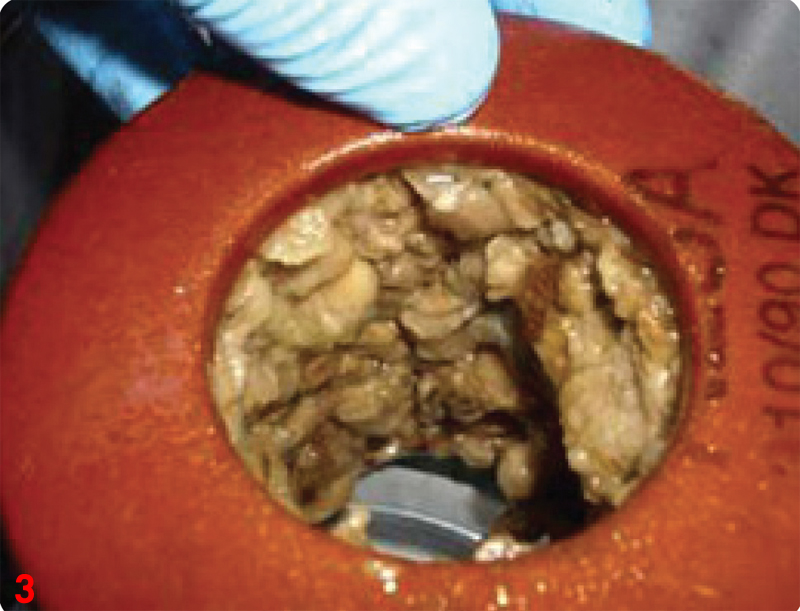

Diesel fuel is an unstable organic liquid and acts as a food for certain fungi (Cladisporium resinae). The spores are in the air and contaminate the fuel. The growth of the fungi happens wherever diesel and water come together and under optimum temperature conditions (Fig 3). Many modern diesel systems continually circulate and filter fuel between the tank and the engine, returning warm diesel to the tank and creating the perfect environment for fungal growth. The waste product of the fungi contaminates the fuel and clogs the fuel lines. The solution is regular maintenance using a quality filter that will remove the water from the fuel and prevent the formation of the fungi.

The Blue Print range

Blue Print has a range of more than 420 fuel filters covering over 69% of all passenger cars and light commercial vehicles. Its supply of fuel filters is manufactured to meet or exceed OE specifications ensuring the correct fuel flow and efficiency, whilst offering engine and fuel system protection.