Dixons of Pudsey’s Helen Dixon writes on the workshop’s observations of Midtronics’ CPX-900 battery analyser.

The opportunity arose to test the Midtronics CPX-900 battery analyser earlier this year and considering ours had just bitten the dust, we decided to give it a try. The tester is described by the brand thus: “Advanced diagnostics in a handheld one-piece diagnostic tool. The CPX-900 features Conductance Profiling, a patented Midtronics technology that identifies batteries with low reserve capacity, a key capability to accurately diagnose the increasing electrical demands placed on modern vehicles.”

The tester arrived quickly as promised and it was up to me to set it up for the workshop. Setting up was okay – it requires some effort with everything you need to input so make sure you have 20 minutes or so to spare to input everything and set up the wifi. It comes with a paper roll installed for the printer, but beware – the roll amount is small! It does however come with three spare rolls and a dongle with the instructions on. Once set up, it does a search for updates. You can manually search for updates periodically too – thus ensuring it is always up-to-date.

On to the test!

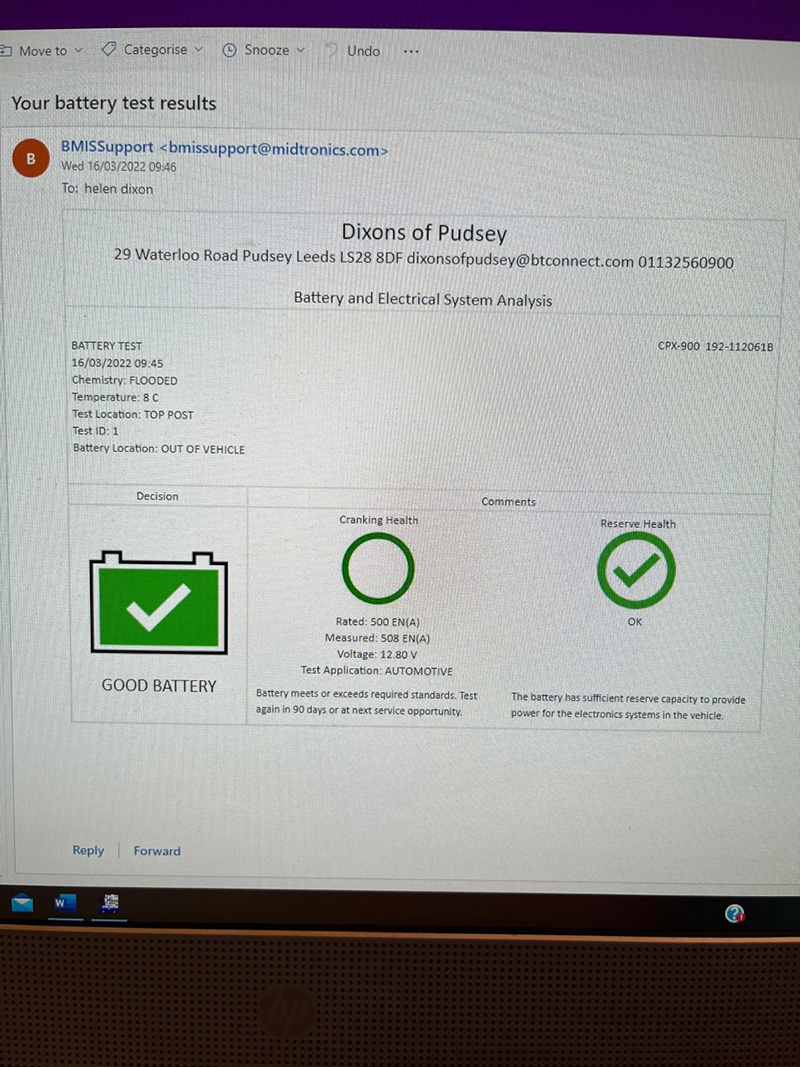

The menu and machine itself are relatively straight forward to use – well, I thought so anyway. Simple button navigation between car/truck/motorcycle/new battery etc. ensures you get to the correct screen and test as quickly as possible. The testing instructions are on screen to guide you with picture prompts too when needed, for example capturing the temperature of a battery. The results are plain and easy to read on screen and you have the choice to either print the results or email them directly to yourself for printing or emailing to the customer. We like the emailed version as it is in colour and easy for the customer to understand. We have noticed that there have been a few occasions where the printer has jammed, which is frustrating, so now if it is a test result that we are passing onto a customer we just email them over. A handy feature, though, is the history button on the device menu. This enables you to go back through the history on the device and see the results, so if someone had been in a few days previous for a test and returns, you can check the history on the device if needed.

We have so far tested lead acid, flat plate glass matt and spiral AGM batteries, car, motorcycle, and even invalid carriage batteries. We have yet to test on lithium so cannot comment on that yet. It also has a “Look up by VIN” facility, which in all honesty for us is a little difficult to use but there if needed. When using with batteries with clamps, you can’t see the AmpH on the battery to input for the test, so on these occasions VIN is useful, albeit in our opinion awkward.

The tester really came into its own on a recent job. A distressed customer brought in her Kia complaining that the car kept cutting out at random moments, with seemingly no rhyme nor reason. She jumpstarted the battery a few times and had even gone so far as to get a battery test at a different garage.

They ran a basic test and told her everything was alright and sent her on her way. Luckily, she came to us for a second opinion. We ran the initial test and it said the battery was ok. We decided then to run an in-depth diagnostic test and the full test which showed that when the tester put the car under load, it was clear it needed a new battery, which we fitted for her there and then. All in all, the CPX-900’s diagnostic capability resulted in a great job for us and a working order car for a very happy customer.

Jobs like the one I’ve just described made us appreciate the CPX-900, however I imagine many small workshops like ours would have to think twice about the investment. At the end of the day it really depends on what you are looking for in a tester and how much you will get to use it. It’s an expensive bit of kit and will be more capable than what’s really needed for many workshops, however it’s been a good asset to our workshop and indispensable for certain jobs.