Maintenance and replacement tips from Nissens.

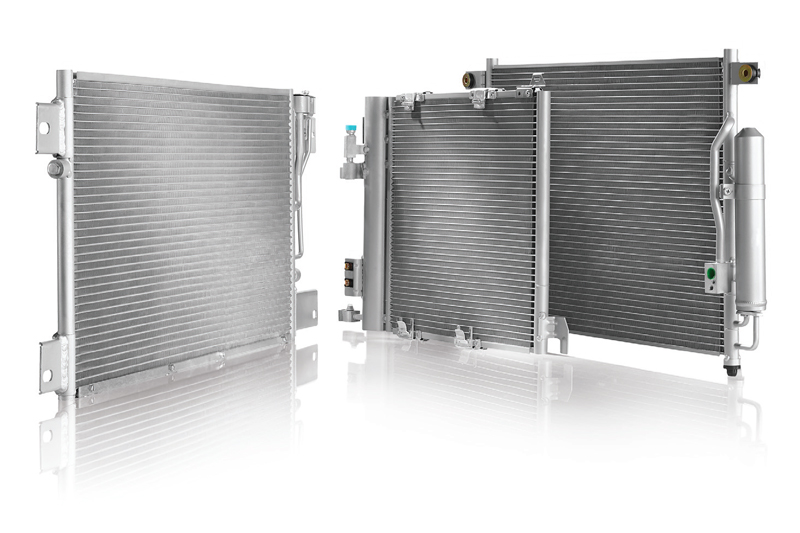

The air conditioning condenser is one of the most critical parts of the A/C system, as it ensures that the refrigerant/oil mixture is maintained within its correct operating parameters and also helps to keep the overall A/C system working properly. So, replacement condensers of the appropriate design and materials are critical to secure the long-term health and performance of the system.

The condenser is relatively fragile and its position at the front of the vehicle can expose it to harsh conditions which, over time can cause it to deteriorate. Condenser failures are therefore relatively common, but can have various root causes, such as mechanical damage from careless service, insect or dust penetration or impacts from road debris, for example. In addition, de-icing salts used in the winter can lead to corrosion, causing the condenser’s surface to weaken and leak. Furthermore, overly dirty surfaces can limit the condenser’s heat exchange performance.

The condenser’s contribution on the A/C system’s performance should not be ignored. Even if it is still partially working, a condenser in poor condition can lead to related failures such as damage to, or even complete seizure of, the compressor, which can occur quite quickly and can be costly to replace.

As a result, Nissens recommends that technicians undertake thorough condenser inspection during a vehicle’s annual service, that any signs of damage should be investigated, and the root cause eliminated, before a replacement is fitted.

Avoiding common problems

- Replace the condenser with a new unit if the tubes or fins are visibly damaged and always handle the new condenser properly and do not disregard any light damage on its surface.

- Learn and apply the basic A/C system diagnostic methods when troubleshooting the system and the condenser. Therefore always assess the condition of the oil and gas mixture using a sight-glass tool, as well as the A/C loop’s pressure and temperature diagnostics.

- Carry out a regular visual inspection of the entire A/C system, specifically the condenser’s surface, joints, and couplings. Pay particular attention to the bottom part of the condenser, where tubes and fins are most often exposed to humidity and aggressive salt spray. If there are any signs of leakage or missing/deteriorated fins, replace the condenser.

- Never ignore soiling and debris that may cover the condenser surface. If possible, remove or gently clean the surface, but never use pressure cleaners on the fragile condenser surface. If stubborn soiling proves to be too difficult to remove without causing damage, the condenser must be replaced.

- Eliminate sources of abnormal soiling on the condenser surface, for example oil leaks from other engine components like the intercooler, turbo or the engine block. Repair any refrigerant leaks from the couplings, but keep in mind a leaky condenser cannot be repaired, so avoid gluing or using leak-stopping agents.

- The receiver dryer must always be replaced whenever the system has been opened (e.g. if components in the A/C loop have been replaced) or exposed to ambient air or moisture intrusion by a severe leak, for example.

- Flush the system after a compressor breakdown and after concluding the system has suffered contamination, but be aware that the majority of modern condensers cannot be flushed and so should be replaced. After flushing, always use the recommended type and volume of oil and refrigerant.

- When replacing the condenser, choose only a good quality replacement that incorporates corrosion protection, as this will considerably prolong its lifespan.