Dayco details the importance of efficient and effective thermal management to the running of ever cleaner vehicle engines.

As independent workshops will be acutely aware, in order for vehicle manufacturers (VMs) to achieve the engine emission and fuel consumption reductions that have been imposed by worldwide legislation, every aspect of engine performance is minutely examined to ensure that all its systems work in unison.

Central to this objective is effective thermal management, which is why, with engineering partners such as Dayco, the VMs have developed solutions or new concepts to ensure their engines not only reach their operating temperatures as quickly as possible, but are maintained at these optimal working levels.

Electric water pumps (epumps) that can be activated instantaneously, alongside design solutions for mechanical pumps, such as those with vane shields or Dayco’s friction wheel, which can provide an instant response to coolant temperature changes, therefore play an important part.

Effective thermal control in all areas of the engine from initial start-up until reaching its designed operating temperature, whether in hot spots such as around the cylinder head or cooler zones elsewhere, is also vital in to maintain the VMs claimed emissions figures, and although easily overlooked, it is the humble thermostat that ensures that this is correctly managed.

Thermostat problems and solutions

Although generally reliable, AASA 2020 report data shows that over a five-year period from 2014, the average thermostat failure rate has steadily increased to almost 5 per cent. At the same time, the percentage of vehicles fitted with integrated thermostat housings and MAP thermostats, rather than a traditional thermostat design, has grown from 55 per cent to 80 per cent.

The 1.4 and 1.6-litre petrol and 1.6- litre diesel engines used in the second generation (R56/57) Mini feature a thermostat housing that is prone to be the source of leaks in the coolant system, for example. These problems are generally caused by either excessive heat from the exhaust manifold or oil contamination. It also not uncommon for the thermostat valve to stick, which can result in overheating.

Integrated housings like this are complex products and this directly affects their predicted service life and crucially, their cost, which is why they should not be considered an ‘anything will do’ product, as the quality will directly affect both their ability to operate within the VMs’ strict performance parameters and their expected service life, so OE quality must be the benchmark.

Dayco’s extensive technological knowhow and drive to ensure its products deliver to the highest levels of performance means that a combination of precision couplings and quality materials has enabled the company to supply a comprehensive range of thermostats that are of OE standard in their quality, safety, efficiency and durability.

Water pump kits

Over the last few years, VMs have also moved to integrate the water pump into the primary drive (timing) system, rather than it being driven by the auxiliary belt.

This has a direct effect on the aftermarket because, in contrast to the auxiliary belt, which rarely has a scheduled replacement interval, the timing belt does, and this means that technicians come into contact with the water pump more frequently than previously and it is therefore far easier for them to assess its condition. As a consequence, more are found to be either in need of replacement or are being changed as a ‘best practice’ precaution, so sales are on the rise.

Helpfully, power transmission manufacturers such as Dayco, have proactively responded to this development by adding a water pump to their timing belt kits to provide workshops with a complete aftermarket replacement solution.

Designated by the KTBWP classification, each of Dayco’s 340 plus water pump kits includes the replacement pump alongside the belt, tensioner and idler combination, with 96 of these references containing the patented Dayco HT (high tenacity) or ‘white’ belt.

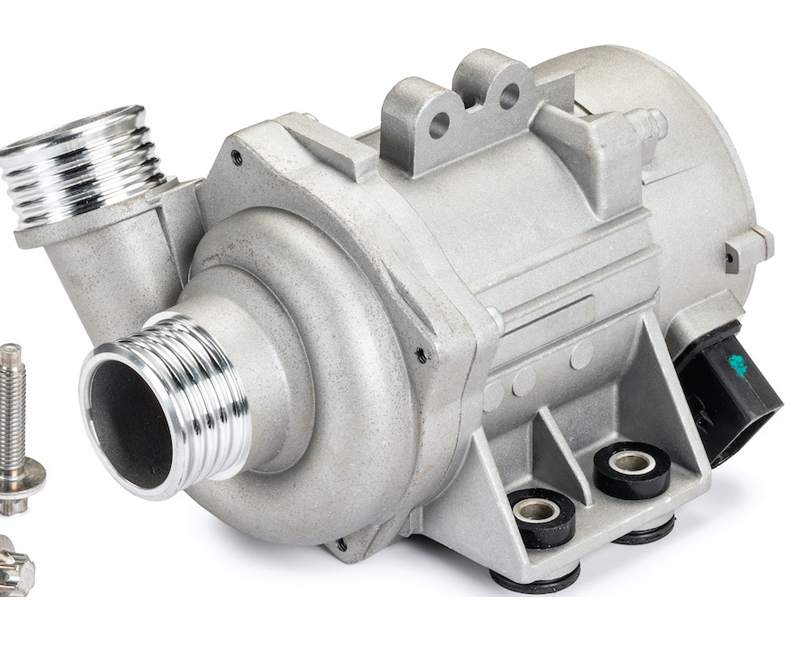

Electric water pumps

Reflecting the developments in automotive design and the huge growth in, first hybrid and now pure electric drivetrains, e-pumps have become a growing presence in the aftermarket, as these vehicles are now entering the independent workshop.

For electric vehicles and many hybrid applications, e-pumps are the only solution able to effectively ensure the correct temperature management of the vehicle’s inverters and battery packs, for example. In addition, to reduce emissions and maximise the efficiencies of combustion engine powered models, reaching and maintaining different operating temperatures around the engine is a necessity.

To optimise the combustion process for example, the cylinder head area needs to run several degrees hotter than the block, where, to enhance the performance characteristics of the oil, it needs to run cooler. These differences would not be possible without split, or dual, cooling systems and the use of additional, electrically operated ‘on demand’ e-pumps to supplement, and in some applications, replace, the system’s mechanical pump.

So, to provide workshops with the service and repair solutions they need, Dayco introduced a wide range of e-pumps, which are naturally manufactured to OE equivalent standards, and reflect the requirements of an ever-changing market.

In addition to primary e-pumps and reflecting the fact that some modern applications can have up to four e-pumps undertaking individual and collective operations, the Dayco range also includes auxiliary e-pumps and cooling system support e-pumps.

Naturally, as would be expected of a company that consistently demonstrates such high levels of technical competence, a supporting catalogue, with comprehensive cross-reference data and imagery, is instantly accessible through the Dayco website and app, as well as via TecDoc.