When replacing shock absorbers, it is very important to install them in pairs. Monroe tells PMM readers why this is the case.

When functioning properly, a vehicle’s suspension promotes precise steering control and handling, contributes to a more stable and comfortable ride, reduces braking distance and protects the vehicle’s tyres from abnormal wear. Also, the suspension helps increase overall driving safety in a wide range of road and weather conditions.

When not functioning properly – including when shock absorbers and other components are worn out or damaged – the suspension might not be able to provide these critical benefits. This is why each suspension component should be inspected every 12,500 miles or at least once per year and immediately replaced when signs of wear are detected.

But simply replacing worn suspension components isn’t enough, says Monroe. Installers must also remember to replace new shock absorbers in pairs and performing the complete job by installing new protection and mounting kits, which are critical to obtain the right performance of those important safety elements.

Why are they important?

The most important benefit of shock absorbers is to help hold the vehicle’s wheels against the driving surface for increased traction and control. As the vehicle encounters uneven road (or off-road) surfaces, the suspension moves vertically to help maintain stability, control and passenger comfort. Maintaining a strong connection between the tyres and driving surface is a critical part of this job because it helps preserve steering and braking control as well as overall vehicle stability. However, in order to perform these functions effectively, every shock must be in good working condition.

Why should shock absorbers be replaced in pairs?

Any time a shock absorber needs to be replaced, its companion across the same axle (front or rear) must also be replaced to ensure that at least both shocks are in equivalent working condition. Because a new shock has not yet experienced any internal wear, pairing it with an older unit is likely to create uneven damping characteristics across the axle. This can cause the new shock to overcompensate, putting it at a higher risk of damage and premature wear.

Conduct frequent and thorough inspections

Monroe recommends inspections of shocks absorbers and struts every 12,500 miles as well as during all routine maintenance appointments. Technicians should check for a number of common indicators that would warrant replacement, including damaged steering and suspension ball joints, poor steering response, fluid leaks from the shock or strut body, ‘cupped’ and uneven tyre wear, excessive vehicle bounce, and/or leaning or swaying during lane changes.

If any of these conditions are evident, replace both the damaged shock and the corresponding unit across the vehicle.

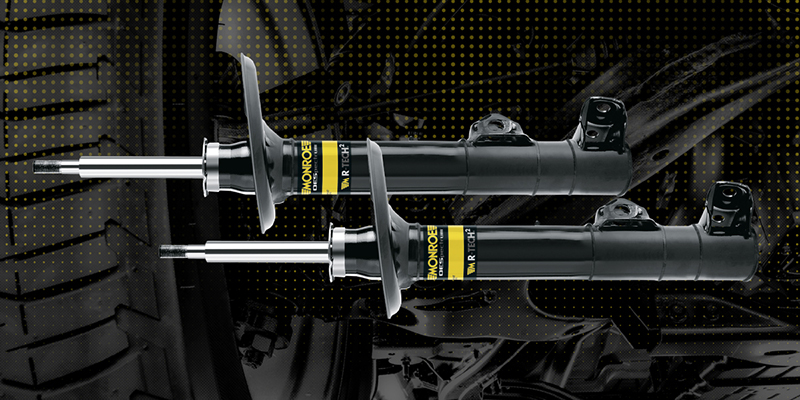

Monroe’s offerings

Monroe original shock absorbers feature the same technologies – and are often manufactured in the same Monroe facilities – as the original equipment shocks found on millions of passenger vehicles. To ensure the repair is done right the first time, always install the new shocks in pairs and, when applicable, use the corresponding new Monroe shock mounting and protection kits to achieve smooth, quiet, precise and long-lasting performance.

Troubleshooting shock absorbers

Monroe provides an easy-to-understand guide to some common problems with shock absorbers:

Incorrect fitment

Incorrect alignment – shock absorbers damaged by a lack of wheel alignment.

Wrong cartridge torque – damage to the cartridge because of excessive or not enough tightening of the torque of the upper nut fastening to the suspension column.

Use of incorrect tooling – the use of the right tool in the assembly and dismantling process is one of the most important factors to guarantee the perfect operation of the new components of the suspension system when it is installed on the vehicle.

Incorrect use

Shock absorber breakage due to extreme impacts – This failure occurs when the shock is exposed to compression forces for which it has not been designed. Structural damage that can occur includes bending or breaking of the piston rod, broken mounts, a bent or broken housing, and breakage of internal components.

Bushings damaged due to overloading – damage caused to the rubber

Pneumatic spring damaged – This occurs when the rubber in the pneumatic spring of the load-compensating shock absorber is damaged, producing a crack resulting in air loss, putting the compensation system out of action.