Shaftec provides readers of PMM with a guide to maintaining and replacing customers’ propshafts – a new offering from the remanufacturing experts.

Back in August, Shaftec introduced its first new product launch in ten years – a comprehensive range of propshafts. At launch, the surcharge-free programme totalled 170 OE-matched quality parts for the European aftermarket, and there are already more in development. Let’s take a look in more detail at what the part is, what it does and how to tell if it’s having problems and needs changing, before offering readers a few hints and tips on how to fit them correctly.

The propeller or propshaft makes the vehicle move by connecting the rear differential to the engine and the transmission system. This mechanical component is shaped like a tube that allows the transmission to power differential, and you can have up to three on some 4WD vehicles.

The handling of each propshaft is designed according to the class of vehicle it will be fitted to. In line with this, Shaftec’s programme caters for all vehicle sizes, from the smallest to the largest. Furthermore, when it comes to ordering product for ease of identification, each component in the Shaftec programme is prefaced SPS followed by a three digit code.

The programme caters for cross class models produced by most vehicle manufacturers active across the European car parc. Typical examples of applications per class are shown below:

Rear Wheel Drive (RWD) – BMW 5 and Mercedes C Class

Four Wheel Drive (4WD) – Land Rover, Range Rover and Toyota Landcruiser.

These vehicles are good for off roading, often have differential locks and a low range. You can have up to three propshafts on a 4WD vehicle.

All Wheel Drive (AWD) – Audi Q7, Jeep Grand Cherokee, Ford Edge, Audi A4 Allroad, BMW xDrive, Mercedes 4 Matic, Golf Alltrack and VW 4motion.

AWDs are similar in power to 4WD but are designed for speed and handling.

Light Commercial Vehicles (LCV) – Mercedes Benz Sprinter 3.5-ton van & Nissan NP300 Navara.

The prop shaft won’t instantly fail, so don’t worry – drivers get plenty of notice as they deteriorate over time.

Common symptoms

When the propshaft needs attention, the driver will probably first hear a rattling or clunking sound. They may also hear squeaking noises when they accelerate or decelerate, and the sound will go away if you are traveling at high speed for a consistent amount of time. If your customer experiences any of these symptoms, you need to investigate the part, because after the noises will come the vibrations and a failing propshaft will make the vehicle tremble and shake. The next sign is that the driver will start to feel resistance when they try and turn the car. By now they may well have waited too long to get the part changed and it could well lead to a much more expensive job.

Installation tips

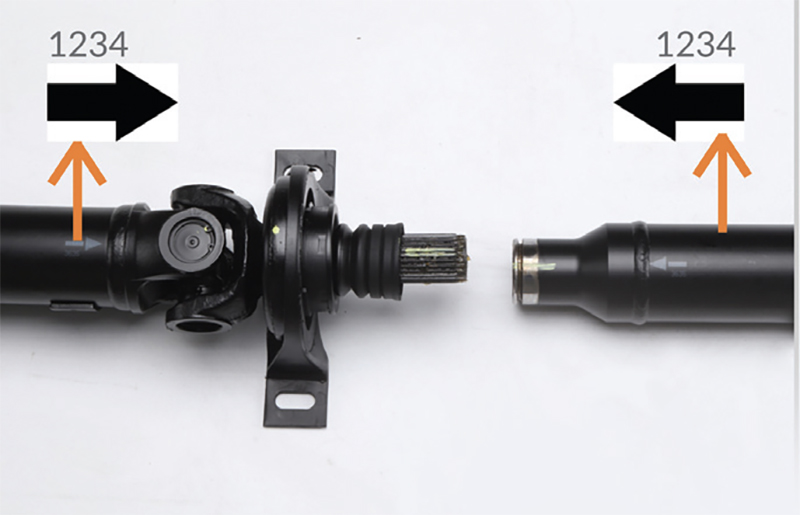

Seperated Propshaft sections need to be matched up correctly before installation to ensure correct balancing.

Match:

Each section should be matched up to the corresponding number/arrow.

Eg. 1234 -> <- 1234

Align:

Align each corresponding number/arrow and insert sections together, ensuring the rubber gaiters are correctly located in the groove.

Offering extensive car parc coverage, the programme of one-, two- and three-piece shafts covers rear, all and four-wheel drive passenger cars and light commercial vehicle applications. As with all its safety critical parts, Shaftec tests all of its products in line with strict industry guides to ensure material quality and strength. All parts are engineered for low NVH (noise vibration harshness) 100 per cent balanced and fully inspected.

Note: Failure to align the arrows and numbers correctly could cause serious vibrations and invalidate the warranty.