Suspension accounts for the highest failure items in the MOT, 21 per cent of all failure items in fact. Do yourself and your customers a favour by looking out for the signs of shock absorber failure and taking preventative action. Here, Monroe’s expert support team, the Garage Gurus take a look at some common issues with shock absorbers.

Loss of damping capability, breakage of the rod

A common customer complaint stems from the incorrect tightening torque of the strut’s top nut. This nut holds together the strut, the top mounting kit and the spring. The top nut should be installed correctly and tightened with a very specific torque, which in most cases ranges from 41 nm to 68 nm – far below the torque generated by a pneumatic torque wrench. When the strut’s top nut is overtightened, the whole strut assembly can break free from its location. If this happens on the road, then it can cause a serious accident. That’s why it’s important that, during the fitting process, all bolts and nuts should be tightened using a torque wrench to the manufacturer’s recommended specifications.

Do not use an uncontrolled tightening torque for any threaded connection, including the top nut of the strut assembly.

During troubleshooting, be sure to inspect the top nut’s surfaces, as impact guns often leave tell-tale signs. Overtightening often causes the stem to break at an acute angle, while the vibrations induced by impact guns can also loosen the nut on the other side of the piston rod.

Damaged rod threads

Another common problem is damage to the stem threads during installation. This happens during fitting if the top nut is placed incorrectly over the rod thread and then tightened with an air gun. This will damage the thread. In addition, if the mounting kit washers are installed in the incorrect order, one may become loose, hitting the lower part of the rod stem. As well as creating noise, this will often lead to damage over part of the thread or the rod itself.

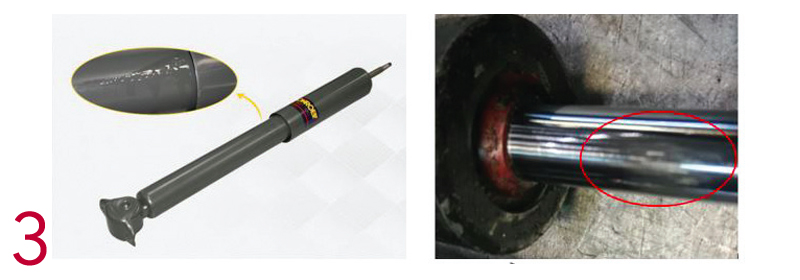

Oil and gas leakage

A common failure occurs when an installer uses pliers to hold the strut’s piston rod while tightening the upper nut. This causes characteristic damage to the chromium surface of the piston rod with marks appearing on both sides of the rod corresponding to where the pliers were used. Once the shock absorber is compressed, the damaged area of the piston rod passes through the strut’s seal, tearing it, and leading to oil and gas leakage. This problem can be easily avoided with the use of suitable tools to hold the rod in place while tightening the top nut to the proper torque.

Too stiff suspension

The position of the protection kit compression bumper is very important. A common mistake during installation is to pull the compression bumper down to the bottom of the strut to gain access to the rod when attempting to tighten the top nut. However, this causes the bumper to prevent proper movement of the suspension and creates an extremely hard ride. Correct installation involves simply moving the compression bumper (the yellow part in Fig.2) to the top of the rod, leaving around one finger’s gap to the bottom surface of the mounting kit.

Blocked shock absorber, paint damage, oil leakage

If a shock absorber appears to have lost paint on one side of the housing, this is most likely due to misalignment of the shock absorber during installation. It often happens when the shock absorber mountings are tightened while the car is raised on a 2-point lift with the wheels hanging freely with fully extended shocks. The rubber element of the silent block acts like a spring and is designed to elastically deform during rotation of 45 degrees in each direction. If the mountings are tightened with the suspension fully extended, when the car is lowered to the ground the rubber silent blocks become fully turned by more than 45 degrees.

Once the driver climbs aboard, the extra load further exacerbates the problem, and the shock absorber becomes completely blocked. It may even experience excessive side force, forcing it into a parabolic shape, and this will typically cause the rear of the car to be raised in relation to the front. If spotted quickly, it can be corrected by undoing the shock mountings with the car on the ground and retightening to the recommended torque settings.

In the pictures below we can see the consequences of this problem: the dirt shield edge starts to touch the housing at one side and scratches the paint. The side force applied to the rod deforms the oil seal causing it to leak. Overheating often leaves traces further behind, such as a discoloration on one side of the rod. The ideal way to finally tighten shock absorber’s mounts is to do it under load with the car on the ground and with one person inside. If accessing the mountings in this position is difficult, it is possible to set the distance between two eyelets of the shock in accordance with the installation instructions. With the part on the table, use a marker to draw a line on the housing aligned with the edge of the dirt shield. Install the shock in the car and tighten the mounting by hand. Finally, use a hydraulic jack to lift the axle to align the edge of the dirt shield with the mark made previously and tighten the mountings to the recommended torque.

Shocks with aysmmetric bushing design

Some shocks have an asymmetric bushing design and must be mounted in a certain position in relation to their lower fixing.

These units are designed to use this asymmetric bushing (see picture) to keep the shock absorber operating in its correct position. If the shock absorber is installed with an incorrect orientation of the asymmetric bushing, then the same problem as that described above can occur. In this case, the shock absorber experiences a side force that causes jamming and oil leakage. This problem may also occur if the wheels are not properly aligned after the shock absorbers have been replaced.