PMM hears from the MEYLE technical team on how best to remove and then install a flex disc on a Mercedes S211.

Flex discs need to be able to withstand a great deal; strong forces, impacts and heat can lead to wear and tear or, in the worst case, cause the flex disc to break or fail – with far-reaching consequences for the vehicle and driver. MEYLE’s technical team has, therefore, pulled together the important information required for the successful removal and installation of the spare part, using a Mercedes S211 as an example.

Note: The following information is intended for use by trained professionals. It offers a simplified overview and does not represent the full process. The information and values apply solely to the vehicle described. The vehicle manufacturer’s guidelines and instructions should be followed and always take precedence over the general process shown here.

Removal of the old flex disc

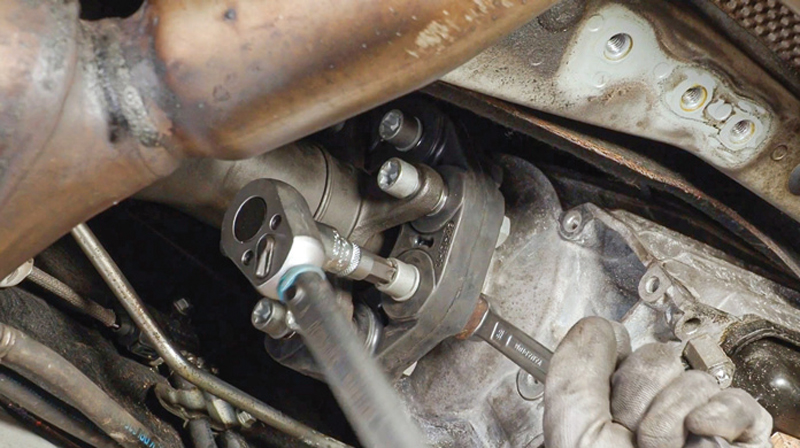

To remove the old flex disc, first expose the cardan shaft. For some vehicles, it may also be necessary to remove the underride guard and/or parts of the exhaust system. For many vehicles, it may make sense to loosen the centre bearing, as this will simplify removal. Once the bolts have been loosened, the flex disc can be removed.

Important: For some vehicles, it’s crucial to remember not to place any weight on the rubber of the vibration absorber when removing the flex disc, as this could tear the vibration absorber. If any flex disc spacers remain in the cardan shaft flange, these need to be removed. Any rust should also be removed.

Inspect the cardan shaft

During the repair, the guide bushings of the cardan shaft should be inspected and replaced if worn. It’s important to sufficiently grease the differential pin and the cardan shaft bushing before it is attached to the differential. The centre bearing of the cardan shaft should also be inspected for wear during repair. Check the rubber mount of the centre bearing to ensure it’s not torn. If the cardan shaft is clearly off-centre in the centre bearing, this is an indication of fatigue in the centre bearing rubber. Worn rubber often leads to sounds and vibrations.

MEYLE tip: MEYLE offers a practical repair kit for the cardan shaft which makes it relatively easy to replace the centre bearing.

Installation of the MEYLE-HD flex disc

It’s extremely important to install the MEYLE-HD flex disc correctly. Unfortunately, flex discs are occasionally installed incorrectly, causing them to fail prematurely. Before installation, it’s important to observe the cardan shaft’s rotational direction when driving forwards. The gearbox flange ‘pulls’ the cardan shaft over the inner winding of the flex disc. The flex disc should be installed accordingly. The same applies to the rear flex disc. Here, the flex disc should be installed in such a way that the cardan shaft flange ‘pulls’ the differential flange over the large inner winding of the flex disc. Once the nuts and bolts are in place, these can be tightened with the specified torque.

MEYLE-HD Flex Disc

The MEYLE-HD flex disc is said to be designed to have a longer service life than the OE. The winding technology employed reduces inner friction and thus the development of heat inside the flex disc. In addition, the push and pull characteristics minimise wear. The improved thread stability inside the MEYLE-HD flex disc improves breaking load, whilst the full-surface yarn packages inside increase torque resistance up to 3,000Nm. The flex disc also reduces torque peaks and boasts wavelength frequency damping and sound insulation. The rubber blend of the flex disc is heat-resistant up to 130°C (270°F), whilst OE parts can usually only withstand temperatures up to 90°C. Like all other MEYLE-HD parts, this part comes with a four-year guarantee.

MEYLE currently offers 80 MEYLE-HD flex disc references for more than 67 million vehicles in Europe, including Mercedes, BMW, VW, Audi and many others.