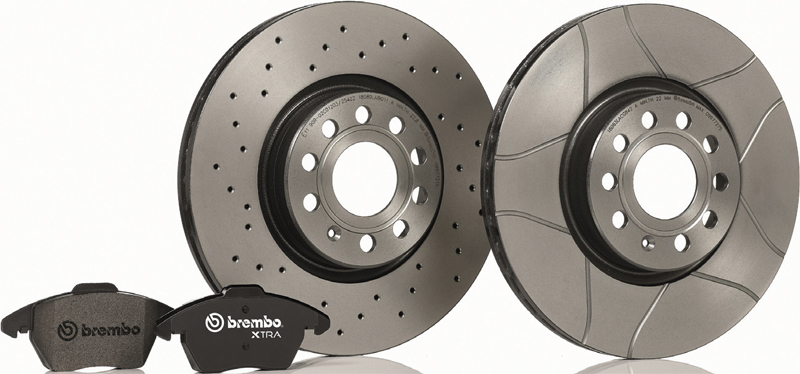

Why replace a standard disc with a drilled or slotted type? Brake systems specialist, Brembo, reveals the advantages of such a replacement and explains how to make the right choice.

When a customer’s car needs new brake discs, sourcing a compatible specification for the vehicle model is only part of the story. Upgrading from a smooth, standard disc to a machined option will also make a significant contribution to overall brake system performance, as well as the car’s appearance.

“The grooves and hole patterns on certain brake discs deliver more than just looks!” explained Marco Moretti, Aftermarket Marketing Director at Brembo. “Every aspect of their design has a specific purpose. For example, compared to a standard disc, they give the pads better grip, drive out water in wet weather, and even keep the brakes cool. There are several different surface patterns on the market, but by understanding the advantages of the key types you can fit the best replacements for each customer’s needs.”

Two of the most effective brake disc surfaces are those featuring grooved slots and cross-drilled holes. Each provides many common benefits in terms of braking performance and safety – but with some useful differences. Find out what vital jobs they do, with Marco’s handy guide:

Performance advantages

1. Improved grip

Cross-drilled holes or slots in a brake disc ensure greater grip between the disc and pad. They do this by making the disc’s surface less continuous, increasing its frictional force – known as the ‘friction coefficient’. This translates into a more immediate response when the brakes are first applied, and improves braking system efficiency overall.

2. Continuous cleaning

Another important advantage of disc holes and grooves is that they clean the pad of sediment during braking. By continuously scraping off old friction material as the pad wears, as well as any ferrous deposits left by the disc itself, only new pad material comes into contact with the disc.

3. Expelling water and gas

Wet discs can affect braking efficiency, but machined disc profiles can help rectify this problem. The holes in cross-drilled designs break up the film of water that may form on the braking surface. Similarly, outward-facing slots expel water build-up on the disc. This means that even in wet conditions, the braking system responds effectively as soon as the pedal is pressed.

Holes and slots are also more efficient than plain designs at dissipating the gases that are released between the pad and the disc at extreme temperatures. These gases are produced when the resins used to make the pad material combust at high temperatures. This can reduce the friction between the disc and the pad, leading to a loss in braking efficiency known as fading. The cross-drilling or grooves in the brake discs allow these gases to be expelled more rapidly, restoring optimum braking conditions. Slotted discs offer optimum water and gas expulsion, so are often selected for the top-level motorsports.

4. Removing heat

In addition, slotted and drilled surfaces are better than plain discs at regulating temperature during braking. By channelling away the heat generated between the braking surfaces of disc and pad, they improve the performance of the entire braking system. Drilled holes are even more efficient at heat dissipation than grooves, making it easier for heat to escape.

Good looks and visual check

In addition, discs with grooves can provide workshops with a useful indication of wear.

“Slots allow direct and immediate control of wear conditions. If any groove has totally faded, the minimum recommended thickness has been reached, so the worn disc must be replaced,” advised Marco.

Marco also revealed that the pattern of holes or grooves can also bring another standout advantage for drivers: “Brake discs with surface profiles give cars a unique, distinctive visual look compared with plain ones. Cross-drilled discs are popular with enthusiasts seeking a sportier drive, as they give the wheel a more aggressive look. Slotted designs offer a more classic, elegant appeal.”

Quality control

Beyond performance and aesthetics, the choice of the brake manufacturer is the final key consideration.

“Producing and testing profiled discs is a specialised job,” confirmed Marco. “The number, size and location of each hole or slot must be designed and machined precisely for each disc, in order to deliver the technical advantages without weakening its structure or wearing the pad too quickly. Bench and road testing in all driving conditions are also essential to meet each vehicle manufacturer’s safety, strength and durability specifications. Selecting a proven, OE quality specialist guarantees this outstanding performance.”

With drilled and slotted discs providing many common advantages but excelling in slightly different ways, it’s crucial for workshops to choose the right product for each braking system, Marco concluded: “Replacing the discs with advanced surface options is the simplest way to upgrade any braking system. Selected correctly for each application and driver need, they will achieve more responsive and efficient braking in all conditions.”

DRILLED DISCS: FIVE MISTAKES TO AVOID

Cross-drilled brake discs might sound like a single, simple type, but beware – performance and quality levels can vary widely between manufacturers. Low cost drilled discs may even fail to meet current braking system safety standards. Marco shares his five tips for avoiding the pitfalls:

1. Never ‘do-it-yourself’

Standard, smooth discs cannot be transformed into drilled discs by modifying them after purchase. Attempting to drill them is the most dangerous mistake that can be made. The structural changes required in drilled discs are very delicate and must be accompanied by appropriate testing to ensure safety. Modified discs are also no longer legally covered by warranty nor approved for road use.

2. All drilled discs are different

One type of drilled disc does not suit all! The number, size and position of the holes in a drilled disc vary widely, and are specifically designed for each vehicle application. In Brembo Xtra discs, they improve performance without compromising resistance, according to the mechanical and heat stresses on the disc.

3. Appreciate the importance of tests

Be aware that some drilled discs on the market have not been tested for performance or duration at all, and others have only been partly assessed. Choose only those brands that have been subjected to full bench and road testing under the most extreme conditions, to meet the performance needs of the cars for which they are designed.

4. Assess materials and ventilation

Drilled discs replace original smooth discs that meet each application’s technical braking requirements. Their materials, ventilation, size and shape tolerances must also meet the same specifications. Some Brembo Xtra discs employ specially tailored materials and hole patterns to give even more resistance to thermal cracking and cooling in the sportiest uses.

5. Consider the pads

Pads play a vital role in the performance, comfort and lifespan of the braking system, and perform even better when paired with higher performance discs.

Follow the drilled disc manufacturer’s recommendations on which brake pad compounds are the best match to ensure optimum brake system performance.