After 20 years of rectangular red and blue tram tracks, Granville has modernised its logo to reflect its evolving brand.

The new logo aims to embody the ethos of Granville, the regular, uniform sides and angles of an equilateral hexagon represent the solid foundation of the business encased in the strongest shape in nature. The G in the icon is split into three parts to show its emphasis on quality, value and customer service. The aim of the modern icon paired with the brand’s traditional font is to remind customers that it still stands for the same fundamentals of service that the company have provided throughout the decades.

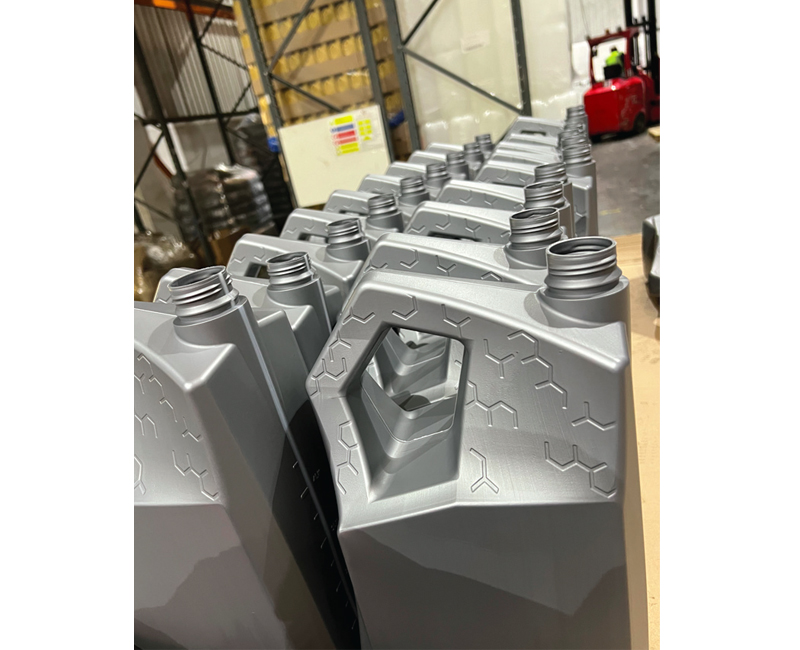

This new logo becomes flexible, with the colour of the icon reflecting the placement and colour scheme of the product on which it is placed. For example, for the more trade oriented Hypalube range, the icon becomes silver to fit in with the quality and value for money the range offers.

Launching oils into the 21st century

Whilst rebranding, the company decided to introduce a completely new look and feel to the Hyalube range, with the new trade bottle being the first to embody the new look. The strong lines and sharp corners are tempered slightly with rounded corners for a modern look whilst the bottle remains unmistakably Granville with the addition of subtle hexagons to add interest and grip to the chunky easy-grip handle.

The labels also feature strong branding with a sophisticated feel and colour coding to differentiate between fully synthetic, semi synthetic and mineral grades as well as the winter/weight rating of the oil. The dark backgrounds said to complement the gun metal grey bottles to present a premium feel to the trade range.

Continued evolution

The coronavirus pandemic caused many businesses to revisit their supply chain, operations, stockholding and review their use of just in time production practices as a result of what would previously have been considered unprecedented global disruption. This allowed Granville to review its operations and supply chain and established a weakness which was in the sourcing of bottles.

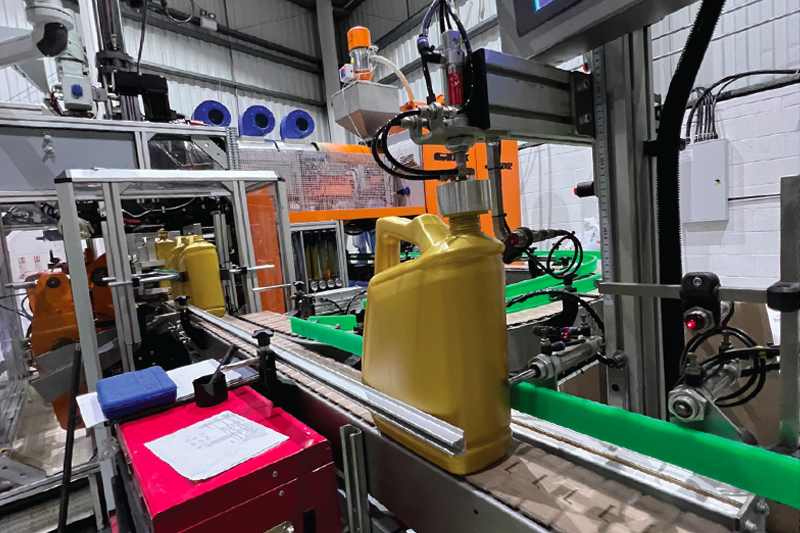

To resolve this, it has invested in blow moulding equipment to be able to manufacture its own bottles as needed. This improves resilience, efficiency and is significantly more environmentally friendly as it will negate at least 100 truck journeys per year saving 1000 tonnes of CO2 per year. The ability to manufacture bottles and fill them on a single site is a major step forward for Granville’s evolution.