To complement its ONE BOX battery testing solution, ECOBAT has developed a video and online assessment to equip technicians with the skills to confidently install stop-start batteries.

Following the successful launch of the ONE BOX stop-start battery testing and installation solution at Automechanika Birmingham last June, ECOBAT Battery Technologies (ECOBAT) has further developed its offering with the release of its free stop-start battery training, assessment and certification.

The first element is a comprehensive and easy-to-follow YouTube video hosted by ECOBAT’s own Christopher Jones. The video provides viewers with a step-by-step guide that takes them through the assessment, removal, replacement and validation processes and introduces them to the four parts that make up the ONE BOX package, with the express aim of enabling technicians to confidently tackle stop-start battery replacement.

Once they have viewed the video, technicians can now undertake the online assessment that covers not just the removal and installation process, but information concerning the battery and the stop-start system, to discover whether they have achieved the necessary score to have passed.

Due to the importance of following the correct procedure, the assessment has a low margin for error, but provided the technician has demonstrated they have understood and crucially, can replicate the process, they will pass and can move onto certification.

By visiting the company’s website the successful applicant can then download their certificate, available in a choice of branded Lucas, Numax or multiple (joint Exide/Lucas/Numax/VARTA) or non-aligned formats. They are then in a position to put into practice their new-found knowledge to the benefit of the motorist and workshop alike.

The video in detail

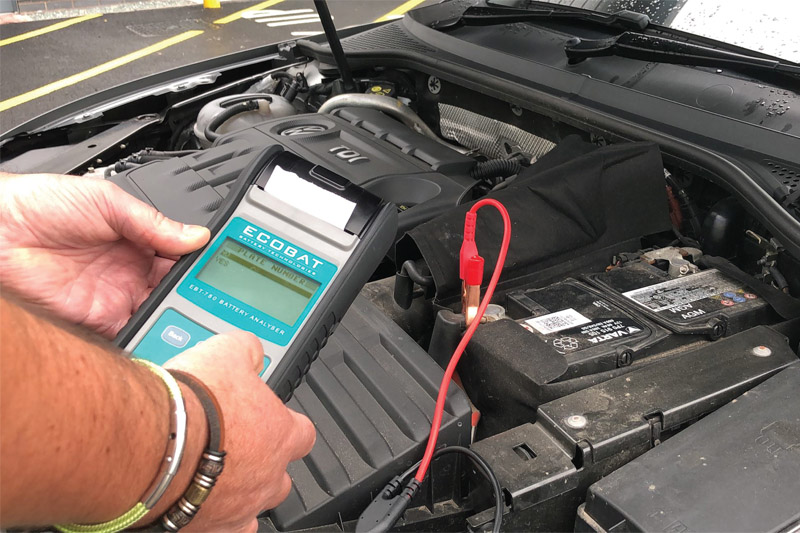

The donor vehicle for the video demonstration is a 2011 VW Passat BlueMotion Tech diesel, and the first step is to carry out an assessment on the condition of the battery, for which Chris uses the EBT780 battery test tool. This vital piece of equipment allows users to understand the true condition of the battery, and as the onscreen result can be printed and given to the owner, it’s easy to demonstrate whether it needs to be replaced or is still fit for purpose.

Battery testing is a principle that ECOBAT recommends technicians conduct on every vehicle that enters the workshop because battery related issues are still the most common cause of vehicle breakdown.

Therefore, irrespective of what the vehicle is originally booked in for or whether it is or isn’t equipped with a stop-start function, testing provides an instant sales opportunity.

If the battery has failed the test and needs to be replaced, then the next tools required from the ONE BOX kit are the charger and the OBD port connector lead. Together they provide a supply feed of power to the vehicle’s electrical systems when the battery is disconnected and removed, and ensures that any memory functions are not lost or have to be re-entered at the conclusion of the work.

Naturally, whether the vehicle is fitted with a stop-start system, which will require either an absorbent glass mat (AGM), enhanced flooded battery (EFB), or is designed for a traditional SLI (starter, lights and ignition) version, identifying the correct replacement for the application is paramount.

In order to do so, technicians simply need to enter the vehicle’s registration number into the ECOBAT battery finder and the appropriate battery from VARTA, Lucas or Numax will be shown, along with its fitting times and installation instructions.

Once the supply feed has been established, removal of the battery begins by disconnecting the lead to the negative terminal followed by the positive, whereas installation of the replacement starts first with the connection of the positive lead and then the negative.

Although some stop-start-equipped vehicles are fitted with a self-diagnosing system and do not require the replacement AGM or EFB battery to be validated, many popular vehicles from a total of 24 manufacturers do, which is where the final tool in the ONE BOX package, the EBT420 validation tool, comes into play.

With the new battery installed, the charger and OBD connector can be removed and the EBT420 validation tool plugged into the OBD port to begin introducing the new battery into the vehicle’s battery management system and returning the charging algorithms to their default settings, as well as turning off the dashboard warning lights. The process is very straightforward as the tool does the work – after inputting the brand and part number, the technician is led through a series of screens that simply needs them to authorise each step to ensure the system is correctly set and the battery is performing as it should.

As Chris states at the conclusion of the video: “replacing AGM and EFB batteries is as simple as that”. It is a clear message that workshops need to grasp to unlock the massive potential still available to independents up and down the country.