Figuring out the right amount of stock to offer can be a challenge, especially during uncertain times like these. PMM speaks to Fatiha Laauich, Pan-European Strategic Marketing Manager at DENSO, to find out how smart consolidation can help you optimise your component stocks.

The European aftermarket has always been adept at evolving to remain competitive in a business landscape driven by fast-changing technology. Workshops demonstrate this daily, with ever-growing diagnostic knowledge and the ability to carry out repairs using the right tools and methods. To offer this full-service package to their customers, they rely on access to the correct parts.

Thanks to continual advancements by parts manufacturers, there is a trend for wholesalers to stock a smaller – but just as widely applicable – range of parts, enabling them to meet customer needs whilst reducing their overheads.

The challenge for these wholesalers is presented when working out how far they can reduce their stock without compromising their offering to workshops, or inadvertently introducing issues with fitting or efficacy. That is where our concept of ‘smart consolidation’ comes in – merging products in a range just enough for wholesalers and workshops to benefit, but not so much that they experience problems.

An optimised offering

Let’s look at one component category where smart consolidation is already at work: lambda sensors. Some manufacturers have identified these parts as a target for range consolidation, and with their variety of wire lengths and fit types, it is easy to see why.

Lambda sensors are crucial components not only in the optimisation of engine performance, but also in reducing vehicle emissions – something that the entire industry knows to be important in the context of global climate goals. Therefore, their performance cannot be compromised.

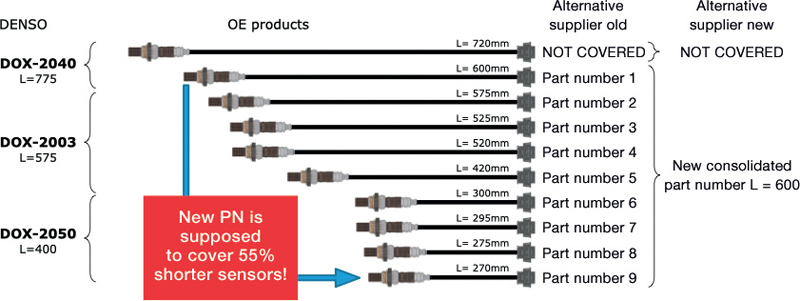

Consider a group of 10 different OE sensors, which all share an identical sensor core, connector type, and pinout. The only difference is their wire lengths. Here, DENSO puts smart consolidation into practice by selecting only three optimised wire lengths, thereby greatly improving the stock efficiency of servicing all related vehicles.

As a result, workshops can ensure maximum vehicle coverage without having to buy a prohibitive amount of stock. Having fewer parts in the workshop makes technicians’ lives easier and the right parts result in efficient and error-free fitting.

When is a saving not a saving?

Would it be possible to take the concept further and reduce the range all the way down to one cable? In theory, yes, and other manufacturers have indeed done this.

However, reduce the range too much, and the constraints begin to outweigh the benefits. In the case of the example in the diagram (Fig 1), the longest possible length would mean an excessive wire length that needs to be secured when the car is running, with cable ties, for example.

With high temperatures, fast moving parts, and heavy vibrations, wire harness fixation is a safety and reliability issue that DENSO is not prepared to compromise on.

In general, the company does not allow wire to be more than 35% over length, depending on the actual wire length. Others in the aftermarket do not apply such a limit, and may even permit wire that is more than 100% over length.

The most extreme version of consolidation can be seen in universal fit sensors. Such sensors will always need additional preparation time, as it is required to cut the wires to length and splice them onto the original wire and connector. Although this provides a perfectly reliable result when done correctly with the right tools, materials, and methods, preparing the sensor will significantly extend the installation time.

Additionally, there are many ways that a less-experienced mechanic could make a mistake; through confusing any of the four wire connections, using a wrong method of connection, soldering instead of mechanical crimp, using the wrong equipment or insufficient sealing.

If any of these occur, it goes without saying that the sensor will not work properly, which will be noticeable in the car’s drivability and fuel consumption. When making their buying decisions, workshops should consider the cost of rectifying these situations, not just the initial costs of the parts.

The ‘smart’ choice

The DENSO lambda sensor range is optimised for smart consolidation, allowing you to maximise benefits without incurring negative impacts. Not only do the sensors themselves match strict quality standards, the segmentation of the range confers the maximum possible benefits to workshops, calculated across the entire life cycle of a product from purchase, to installation, to use.