When customers come into the workshop complaining about their brakes, it’s important to have a thorough understanding of what the problem could be. Here, Juratek explains what brake judder is and what causes it.

Every motorist needs to have confidence in their vehicle’s braking system. So, when you put your foot on the pedal, the last thing you want is to hear excessive squealing or to feel unexpected vibration or judder.

When vibration occurs, many people jump to the conclusion that the disc is warped and needs replacing. So, what is brake judder, and how can it be avoided?

It can be divided into two types: 1. Hot brake judder and 2. Cold brake judder.

Hot Brake Judder

When two surfaces are brought into contact and at least one of them is moving at high speed, friction will be caused. This creates heat which is transmitted to other parts of the braking system.

Brake discs are usually made of cast iron and when this material gets hot it naturally expands and distorts and when cool, returns to its original shape. This natural reaction to heat is consistent and brake discs are designed to handle this and can operate in temperatures up to around 500°C.

If the brake discs exceed the normal operating temperature “Hot” Brake Judder can, sometimes be the consequence.

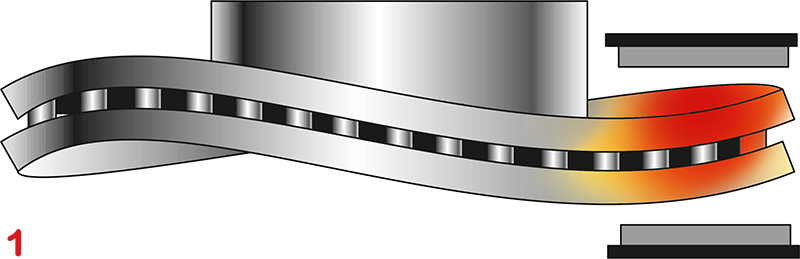

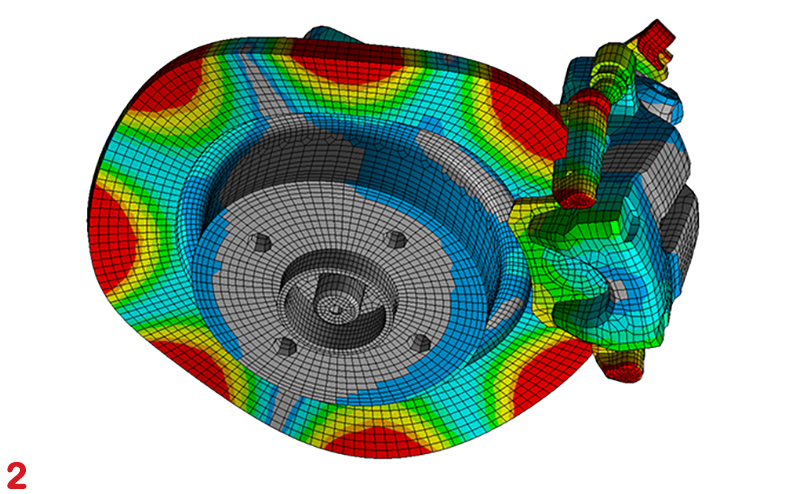

Figs.1 & 2 show an exaggerated view of the effects of temperature on a brake disc. Fig.2a shows a disc that has a number of indicators of disc thermal distortion and excessive heat: firstly the oxidisation (orange colouring); secondly the blue tint to the braking surface; third the dark spots on the disc surface (high spots); and finally the large radial crack where excessive heat has caused permanent damage. All these factors are indicative of distortion caused by excessive temperature.

But what causes excessive heat?

The most common cause is abuse. Brakes are designed to withstand high temperatures, and cool down quickly, if you hit them hard several times in quick succession however, this can cause a phenomenon known as ‘brake fade’, which is when the brakes get so hot they fail to work effectively.

Repeated heavy use of your front brakes might also cause the discs to turn blue. Once these marks appear it means the disc has been permanently damaged and will need to be replaced. Another reason could be that the brake caliper could cease to function properly; this causes the brake pad to remain in contact with the disc even when not braking. Heat will steadily increase and can eventually get so hot the brake disc may crack if rapidly cooled.

Cold brake judder

Incorrect fitting – cold brake judder is almost always a direct result of a fitting problem between brake disc and hub.

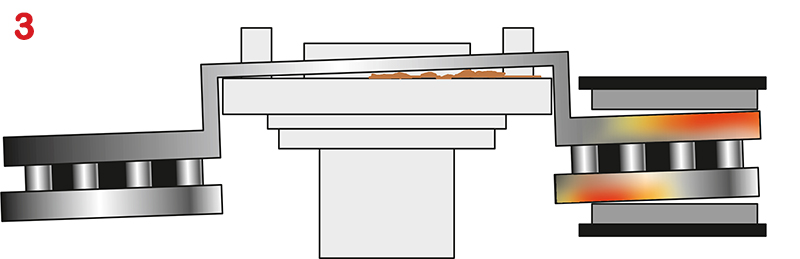

Brake discs and hubs are manufactured to strict tolerances, therefore any rust or other debris that can cause fitting issues, as illustrated in Fig.3, needs to be removed prior to installation.

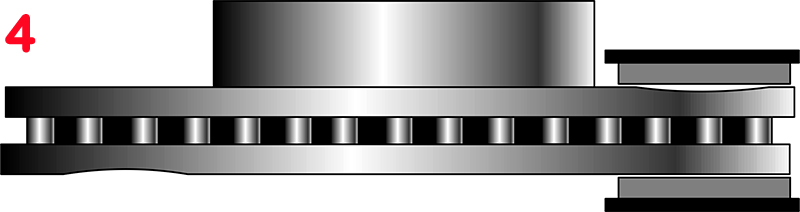

If the disc is installed with too high levels of radial run out the consequence is very light continuous contact between the pad and disc at diametrically opposite points on the disc face in the “brakes off” condition (Fig.4).

With increasing mileage this results in a progressively larger localised variation in the thickness of the disc (DTV – Disc Thickness Variation) which, when the brakes are applied, causes a pulsation to be felt through the brake pedal and steering wheel.

To ensure this does not occur, follow these steps:

- Clean the hub of rust or debris

- Then check the hub for run-out using a dial gauge

- Install the new disc and then check using a dial gauge (Fig.5) mounted close to the outer radius of the disc; the installed value of radial run out should not be greater than 100 microns, and ideally not more than 70 microns

- Choose the right discs – poorly manufactured brake discs can cause brake judder. Reputable manufacturers like Juratek, now manufacture to the strict regulations imposed by UN ECE R90:02, which covers the way a disc is manufactured, and the material used

At Juratek we pride ourselves on the high quality products we supply and our discs are manufactured to the strict geometric tolerances imposed by this regulation. Our discs are manufactured exactly as the OE disc including the vent design, which is specifically designed to maximise the airflow with a vehicle braking system.

In addition, we coat the non-braking surfaces of all of our discs with corrosion resistant paint but the reason we do not coat the braking surface is because this acts as a lubricant between the brake disc and pad and this can impair braking performance.

Good braking systems need more than a good quality brake disc to function and our brake pad range is not only produced to UN ECE R90:02 standard but is also tested to AK Master which is a standard developed by the OEM side of our industry to type approve brake friction material. It goes beyond the tests conducted as part of UN ECE R90:02 and includes vigorous wear and noise tests.

The addition of our unique “initial Performance Strip” which is a strip of green material applied to the surface of the front pads, aids in the initial bedding in stage. In addition, many of our pads contain the fitting kits, which often include bolts, caliper clips and wear leads. As these components corrode or wear over time, they can cause the pads to become loose in the caliper. So, it is essential to change these at the same time.

So, in summary, the issue of brake judder, which is often blamed on a warped disc, is almost never a fault of the product and in most cases is caused by either excessive heat or poor preparation and fitting.