The influx of new hybrid and electric vehicles has sparked increased efforts to develop battery technology. So, does this spell the end of the 12V? PMM, in conjunction with Autodata, investigates the new power supply contenders.

As far back as 1859, the lead acid battery has proven to be an integral component in almost every type of automotive vehicle, including hybrid and electric. Even though hybrid and electric vehicles make use of lithium-ion and nickel-metal hydride batteries to store energy and propel the vehicle, the reliable 12V battery is still utilised to power the vehicle’s 12V electrical system.

The future

Despite the 12V’s loyal service, the automotive industry’s search for the next evolution in battery technology continues as pressures to switch from combustion engine vehicles to hybrids and EVs mount. The definitive objective is to invent a battery capable of storing large amounts of electrical energy while requiring a relatively short period of time to fully recharge. The following examples offer a quick snapshot into some of the new strategies and elements being explored:

- Solid state batteries replace the electrolyte found in current batteries with a solid substance to enhance energy mass. Because operating temperatures are low, any risk of fire or explosion is reduced. These batteries are thought to have a longer lifespan and are also considered cheaper to produce than existing batteries.

- Silicon-based batteries use silicon in lithium-ion batteries. In so doing, the charge capacity is increased, which results in a battery that lasts considerably longer between recharge times. Silicon as a material is abundantly available, which also makes this a very viable option.

- Fluoride-ion battery technology claims to store up to 10 times more energy when compared to current lithium-ion batteries. However, currently, fluoride-ion batteries only work at high temperatures, so this temperature limitation needs to be addressed before this can become a realistic solution.

Clearly, there is still room for improvement and the teachings of the past indicate battery perfection can be a slow and calculated progression. Significant advances in future battery technology are unlikely to be overnight and the industry could expect timing of these advances to run into multiple years or even decades.

Training on the job

Autodata’s battery disconnection and reconnection module provides technicians with all the information they need to efficiently and successfully work with today’s batteries. Features include diagrams that show the locations and procedures for disconnecting batteries; instructions on preparing the battery for disconnection; and a list of electrical components that need to be reset after the battery has been reconnected.

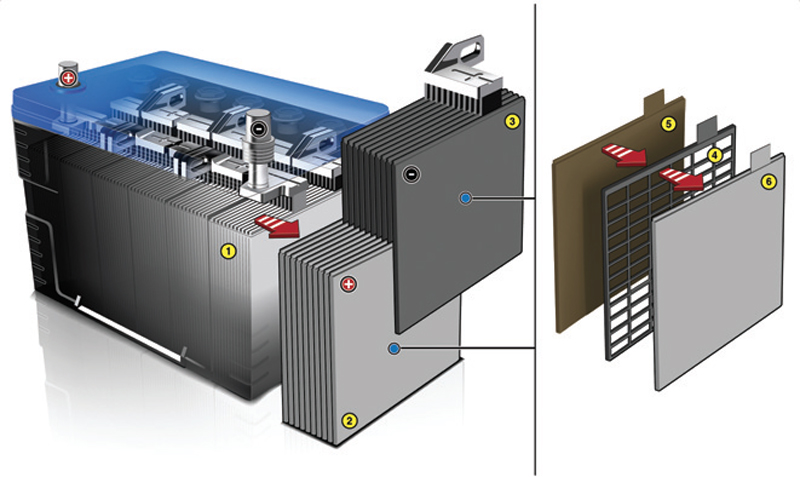

Battery breakdown: 12V lead acid

2. Positive lead dioxide coated plate

3. Negative lead plate

4. Grid

5. Separator

6. Lead plate

Consisting of no moving parts whatsoever inside, the 12V lead acid battery encompasses six galvanic cells, individually capable of holding 2.1V. Each cell incorporates a positive lead dioxide coated plate and a negative lead plate, divided by a grid as well as an insulating material called a separator. The entire structure is encapsulated in a hard-plastic container filled with a liquid solution (electrolyte) made up of sulphuric acid and water. After a charge greater than 2.1V is applied to each cell, a chemical reaction inside the battery is triggered, creating electrical energy ready for use.