Allison Whitney, of Autel, explains why ADAS calibration is the name of the game as the technology becomes all the more common.

There are close to 60 million vehicles with some type of Advanced Driver Assistance System (ADAS) on the road today – 20 major automakers are committed to including Forward Collision Warning (FCW) and city-speed Automatic Emergency Braking (AEB) as standard equipment on their vehicles, starting from September 2022. Audi, Volvo, Mercedes Benz and Tesla have already met that goal.

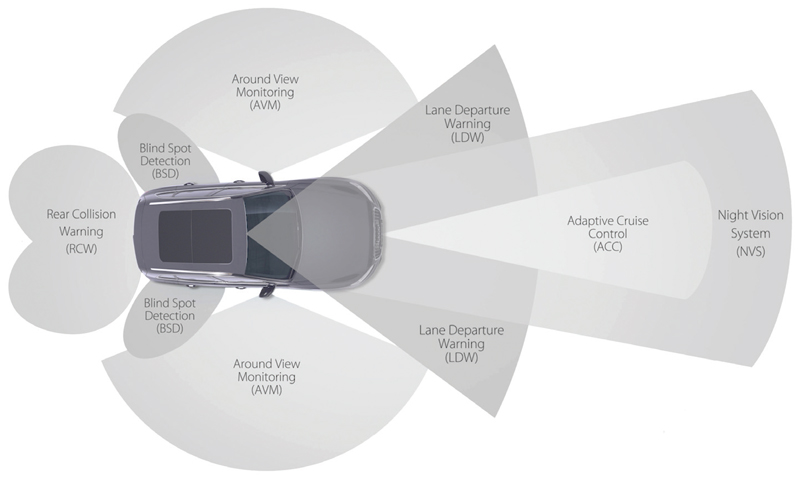

Many, if not most, of these vehicles are equipped with camera-dependent systems such as braking (AEB) with pedestrian detection, and even some Blind Spot Detection (BSD). And, these are just the basic systems at this time. The front-facing cameras are also used in traffic sign recognition, automatic parking, cross-traffic alert and adaptive lighting systems. The emergence of this technology and its increasing popularity has added layers of complexity, time and cost to vehicle repairs, including glass repair and replacement.

Careful calibration

According to AAA in the USA, more than 14.5 million windshields are replaced annually. As the number of vehicles with ADAS-input, such as front-facing and side view mirror cameras rises, auto glass repair centres need to incorporate calibration into their vehicle repair procedures. Regardless of whether the service is sublet to another repair centre, performed by a mobile ADAS calibration technician, or completed in-house, glass focused businesses need to understand their liability to complete the calibration after the windshield replacement before the vehicle is returned to the owner.

Every glass technician will know that if a windshield is replaced or a camera disconnected for whatever reason, the camera will need to be recalibrated. A camera code displayed during a diagnostic scan, deployment of the airbag, an alignment, or a change in suspension, would also necessitate a camera calibration.

A camera calibration is an adjustment of the operating parameters of the camera lens or lenses to capture an image of the environment ahead. Depending on the camera system, the horizontal field of view on a forward-facing camera is between 40 and 70 degrees. During the repair, even the slightest adjustment of this camera’s field of view, will disrupt the system’s ability to accurately ensure the safety it was designed to provide.

Calibrations can be stationary, which involve targets or patterns; dynamic, which involves driving the vehicle in a prescribed manner, including a specific duration, speed and environment; and some vehicles even require both static and dynamic calibrations.

Effective calibration

How important is a calibration to the effectiveness of ADAS? Consider an example from the Insurance Institute for Highway Safety (IIHS) in the USA. The test highlighted how the data from a misaligned front camera can affect the vehicle’s collision avoidance system – a system that is designed to warn the driver of an imminent crash, and then to actively engage the systems to brake the vehicle when the driver fails to act. The IIHS tested a vehicle with a front-facing camera that was misaligned by 0.6 degrees to the right. This variance affected “the perceived collision-threat, thus delaying first the driver prompt or warning to brake, and then delaying when the vehicle itself initiated braking”, according to the IIHS. The result was a warning prompt that gave the driver just 2.8 seconds to respond and gave the vehicle just 0.9 seconds to brake.

Calibration systems

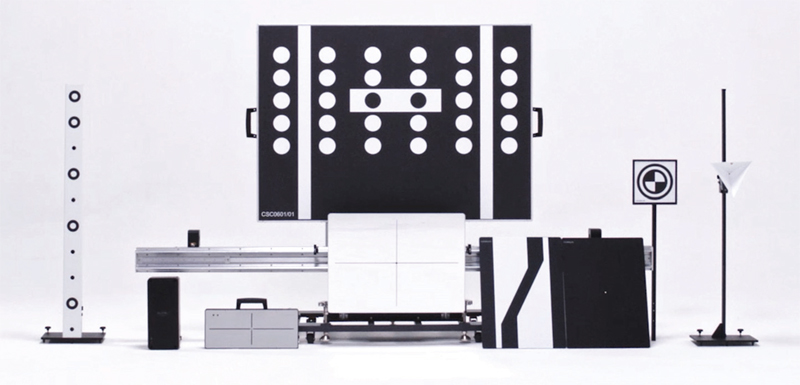

Autel, a leading developer of automotive diagnostic scan tools, produces an advanced ADAS calibration system to enable technicians to efficiently calibrate cameras, night vision, Lidar and radar-based systems that are instrumental to vehicle operations and the safety of passengers.

The company’s calibration systems include patterns, targets, and radar and night vision calibration tools used with the MaxiSYS ADAS software. In addition to communicating with the ADAS modules and initiating calibration, Autel’s ADAS software acts as a training guide for the setup of each calibration, with detailed illustrations highlighting frame positioning, and instructional videos enabling technicians to perform every step of the calibration process.

The tablet displays the basic vehicle requirements before initiating the calibration to ensure consistent vehicle height, such as parking on a level ground, ensuring fuel and fluids are filled, and that the vehicle carries no additional cargo. Each procedure screen lists the tools needed, including the correct vehicle-specific target or pattern part number.

The tablet displays exact OE-specific measurements and easy-to-follow instructions. As automotive manufacturers advance towards an autonomous future, there is little doubt these driver assistance technologies will require technicians and garages to adapt. Autel equipment can help ensure that these garages have the capability to prosper.