PMM hears from Maverick Diagnostics’ Managing Director, Andy Brooke, as he gives an honest appraisal of the diagnostic life.

Vehicle manufacturers now have the ability to change their software on a daily basis, to make improvements, add new chassis numbers and to fix historic software issues. The aftermarket tool manufacturers simply cannot keep up with these changes.

To be clear, aftermarket tools will always have their place. I use them every day, but they will never have the ability to carry out software updates and they will never have anywhere near the depth of an OEM tool. As you and I, the independent workshops already know, the depth of coverage has dropped dramatically off these tools over the last few years.

What about pass-thru? I hear you say. I have been personally involved with PT since 2006. It was a great hope for the aftermarket but it has been a big let-down influenced by the vehicle manufacturers’ security policies.

Pass-thru does not give the full diagnostics access and the speed of programming of an original OEM tool. As you are generally paying by the hour it will cost you more than an OEM tool in the long run.

Remote diagnostic tools give only limited programming functionality. The hourly cost is high as you are not actually doing the job yourself, so not a good return on investment. Plus, if the OEMs have their way, remote diagnostics supplier using OEM tools will be shut down for security violation reasons. They say they can’t keep track of who is using the tool on whose vehicles, this would be a real problem if you solely rely on these remote tools.

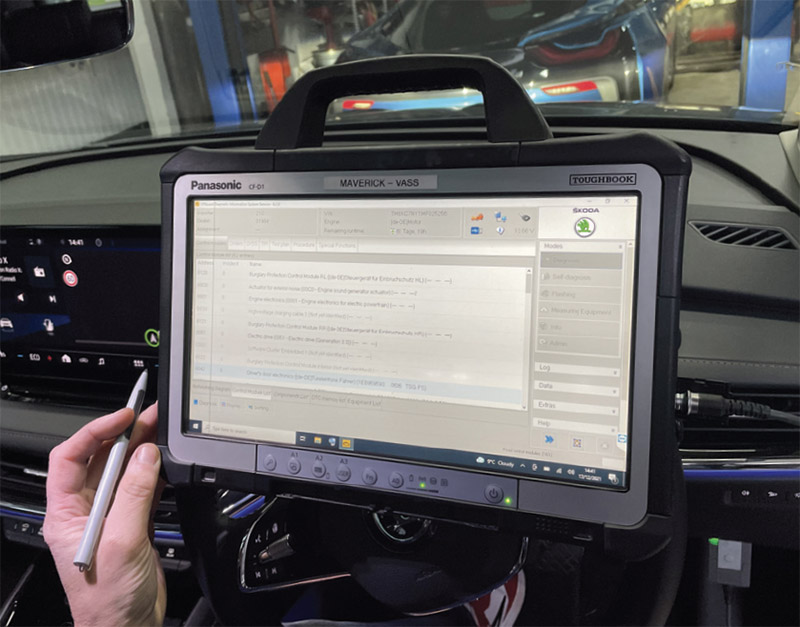

OEM tools present the best option but need regular updating and have ongoing usage costs associated with them, they do give the best option for accurate information and guided diagnostics. There are processes to follow to register with OEMs and you may have to adjust your business plan slightly to get in line with the OEMs’ policies.

To help explain my own diagnostics business philosophy, I want you to ask yourself the question: Do you think a local main dealer technician naturally knows more than you? I doubt it very much. We all know the saying, ‘a bad workman blames his tools’.

This does not apply in the world of modern diagnostics. Due to the vast complexity of vehicles, it levels the playing field – you are only as good as the tools, information, and training available.

Here is how you can turn these complexities into opportunities and a successful business. Because of block exemption rules, you, the independent workshop, have the right to have access to all that OEM information, diagnostic data, diagnostic tools and training that has cost the OEMs millions to develop. This all has a cost, but not as much as you would think: typically €11 per hour – most OEMs offer pay-per-document or by the hour. In other words, you have the right to compete directly with your local main dealer, so why not embrace the challenge?

Next, I ask you to really think about the future of your business: where do you want to be? What vehicle do you want to be fixing in five years’ time? Research and explore what path gives you the best possible return on investment. Finally, start to plan training, tooling and vehicle coverage for at least the next 5-10 years.

I hope you find my guidance useful, these tips have been developed after dealing with 100s of workshops big and small over the last 25 years. Here is a summary of my tips to help you on your way.

1. Don’t bury your head in the sand.

Hybrid/EV, advanced driver systems and advanced digital diagnostics are all already here and in the independent aftermarket workshops.

2. Charge for everything.

As soon as the diagnostic tool is plugged in, start the clock.

3. Use an aftermarket tool as a fast, not best, solution.

Read the initial fault codes, see if it is an easy fix but don’t rely 100 per cent on the results.

4. Use a real live OEM level technical data system to see if there are any technical service bulletins available or known verified fixes, as a lot of problems are well known by OEMs. An increasing number of faults can be fixed by a software update, this can stop you chasing a known fault for days.

5. Don’t Google faults – it is the worst thing you can do. Inevitably you will end up getting tied up in knots with opinions, not verified solutions. It’s the modern version of being told down the pub by your mate.

6. Subscribe to a live vehicle technical support service, this is essential as a second set of eyes on a job and is far cheaper than employing your own group of master techs.

You will learn and earn money while someone else is looking at the problem.

7. Look at what cars you repaired the most during the last few years, think about specialisation or cutting down to five or six key brands to focus your attention on.

8. Look at OEM tools: they are accurate and get around all security issues and software updating issues, they are not expensive or expensive to run and you should pass on the cost to the customer. You will still be cheaper than the local main dealer and you get to keep your customers.

9. Get as much training as possible, whether it’s online or live, invest the time and money. It will profit you in both time and money in the long and short term.

10. If you have not done any training for a while, don’t be tempted jump in too deep, too quickly. Look at doing the basics again such as “sensors and actuators”, things move on very fast, we all need to get refreshed.

11. Invest in a decent IT infrastructure such as LAN sockets in the workshop and decent high speed over 50Mbps broadband. Everything in the future is going cloud-based and updates and diagnostics will eventually be carried out over wifi.

12. Start to invest now. Little and often is best, build up your knowledge bases and training alongside your tools – you don’t want to start the process in five years’ time and be forced to invest a small fortune just to stay in business.