Andrew Bates, MD of Straightset, is arguing you need to be taking wheel alignment in-house and reaping the benefits in the process.

For many independent garages, wheel alignment still feels like a specialist service which is seen as complicated, time-consuming and best subcontracted to a neighbouring workshop. But the truth is, modern alignment systems have made the process simpler, faster and more accessible than ever and garages can unlock valuable new revenue streams as well as enhance customer satisfaction and loyalty, by bringing alignment in-house.

There’s a persistent myth that wheel alignment is difficult. It isn’t. Today’s systems, particularly straightforward CCD (charged coupled device) and advanced 3D options, are built with user-friendliness in mind, guiding technicians through each step on screen, from initial measurement to final adjustment.

At Straightset, we’ve seen firsthand how workshops, hesitant to take on alignment, quickly turn it into a core profit centre with the right equipment, support and training. If you’re one of the many UK garages still subcontracting wheel alignment work, it’s time to bring it back in-house.

Demystifying wheel alignment

Understanding wheel alignment geometry isn’t rocket science but it’s essential for providing customers with a comprehensive, high-quality service. Misalignment affects handling, tyre wear, fuel consumption and compromises safety. Learning the basics of alignment angles enables technicians to diagnose issues like uneven tyre wear, steering pull and poor stability, all of which can be quickly corrected with the right equipment.

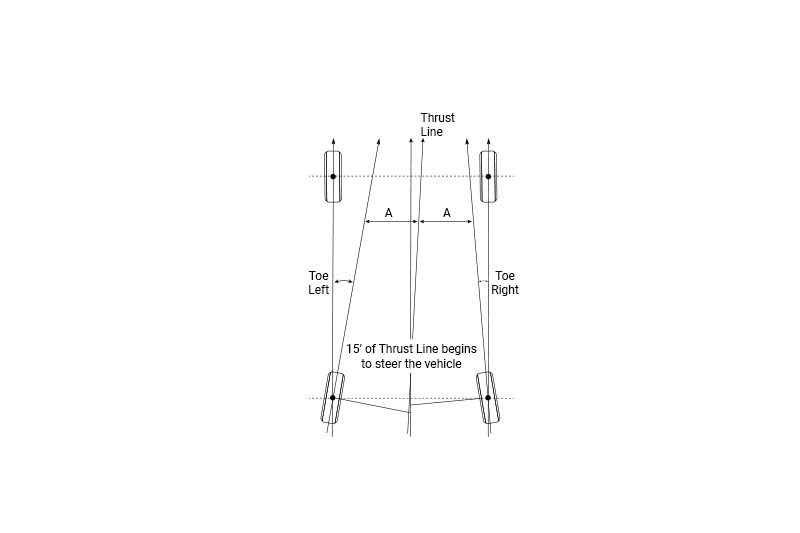

1. Thrust Angle

The direction the rear wheels point in relation to the vehicle’s centreline. Misalignment here causes pulling and off-centre steering as well as tyre wear on one side, making tyre replacements more frequent (Fig.1).

2. Toe

The toe angle is a key factor in preventing feathering across the tread, poor handling and preserving fuel efficiency. Toe alignment determines whether the wheels point inward (toe-in) or outward (toe-out) relative to the centreline when viewed from above.

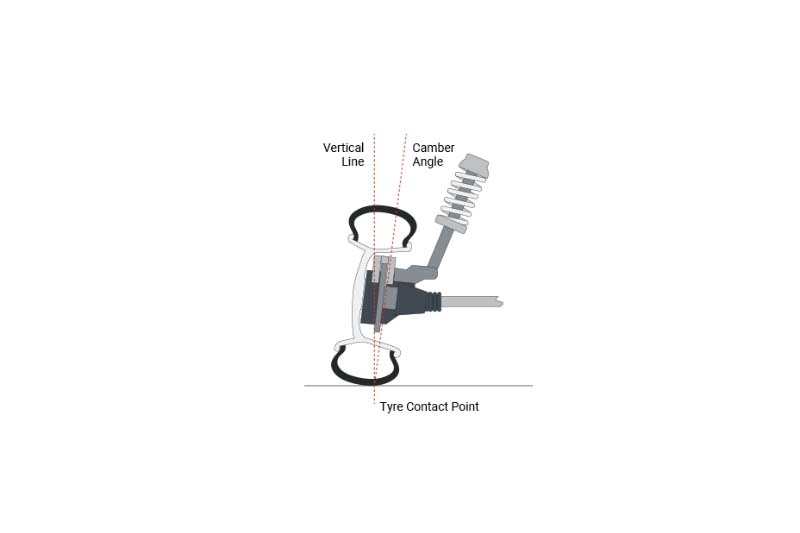

3. Camber

The inward or outward tilt of the wheels viewed from the front. Incorrect camber leads to uneven tyre wear and poor cornering grip, tilting the tyre from vertical, reducing the contact between the tyre and the road even in a straight line (Fig.2).

4. Caster

The tilt of the steering axis from vertical, improving stability and steering response. While some vehicles don’t allow for caster adjustment, technicians knowledgeable about caster can recognise its effect on vehicle behaviour and communicate this effectively to customers (Fig.3).

5. Setback

The forward or rearward position difference between the front wheels whereby excessive setback could indicate structural damage. Detecting setback issues early through alignment checks can help technicians alert customers to potential frame issues before they become safety risks, establishing trust and avoiding future problems for the customer.

Mastering these basics is the foundation of effective wheel alignment and with today’s systems offering onscreen, step-bystep instructions, even entry-level technicians can quickly get to grips with it.

Simple to use

Laser technology in wheel alignment is well established and trusted by many garage owners for its simple yet accurate approach to vehicles alignment.

Green lasers are visible in a much wider range of light conditions, making them effective for indoor and outdoor work all year round, as well as being able to travel over longer distances. Supertracker offers a range of green laser wheel alignment systems such as the STR1 which is a popular, robust, cordless and mobile laser aligner (Fig.4).

Used to accurately measure toe and thrust angles as standard, the green laser technology makes is the perfect product for track days, race teams, mobile wheel alignment, home car enthusiasts as well as tyre shops, MOT stations, used car centres and even operators who are colourblind.

Document the work you do

With many garages needing documentation as evidence of completed work to provide to customers (as well as for insurance purposes), computerised wheel alignment machines represent the most popular technology to address this requirement.

Stop thinking complicated though. Modern aligners have evolved significantly in the last decade. The latest CCD alignment systems feature straightforward interfaces with live help guides and prompts at every stage of the alignment process.

One standout is Beissbarth’s VAS 701011 Q.Lign 3D Wheel Alignment system. The web-based system removes the need for a dedicated PC trolley as it streams directly to any workshop’s TV, laptop or smartphone, displaying instant alignment data, including wheelbase, offsets and centreline measurements. Magnetic clamps allow for fast, precise attachment and the system integrates seamlessly with ADAS calibration equipment (Fig.5).

Notably, Q.Lign is the world’s first fully web-based aligner making a leap forward for workshop integration and ease of use. OEM approvals from brands like Audi, VW, Porsche, Bentley and Lamborghini confirm its precision and reliability, meaning even garages handling high-performance vehicles can trust the results.

Understanding ROI in wheel alignment

Many garages hesitate to invest in wheel alignment equipment due to perceived costs. However, it’s one of the fastest payback investments you can make in workshop equipment. If you charge £50 per alignment and perform just three a week, a quality system could pay for itself within 12-18 months. Factor in the additional tyre sales, suspension work and ADAS calibration opportunities it creates, it’s clear that there are long-term gains in profitability.

The importance of aftercare

One of the biggest risks when investing in new workshop equipment is being left without reliable backup when you need it. That’s why choosing a system supported by a UK-wide aftercare team is essential. When researching your wheel alignment kit, ensure that it is supplied with full technical support, nationwide servicing and access to alignment experts.

Whether you’re new to alignment or upgrading from older equipment, having access to proper training, installation support and rapid service response times ensures your workshop stays operational and profitable.

Alignment is for every workshop

Even workshops that don’t specialise in tyres should consider adding wheel alignment. Vehicles undergoing MOTs, suspension repairs, steering component replacements, or new tyre fittings all benefit from alignment checks. It’s a fast upsell, an easy safety improvement and a valuable customer retention tool.

Full four-wheel alignment ensures vehicles leave your workshop driving straight, maximising tyre life and fuel efficiency while reducing steering complaints and warranty returns.