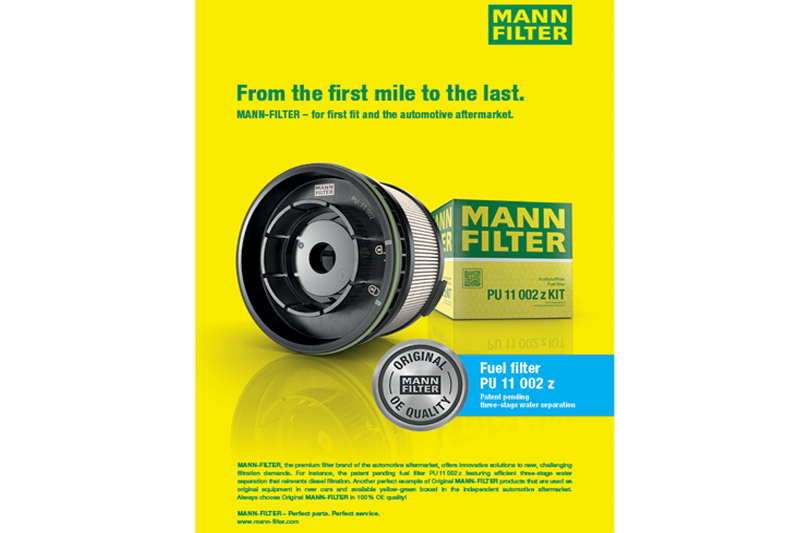

MANN-FILTER has released a fuel filter which protects commercial vehicle diesel injection systems against water and dirt particles.

Even high-quality diesel may contain traces of water, whether from moist air entering through the tank ventilation or from condensation in the large tanks used to store the diesel in petrol stations. However, advanced common rail diesel injection systems with injection pressures of up to 2,500 bar have higher requirements than simple mechanical systems in terms of the purity of the fuel.

Tiny dirt particles and water drops can damage the components of the fuel circuit, which in the worse case can result in system failure. Another challenge is the composition of modern diesel fuels, which have changed greatly in recent years. They contain very little sulfur and have higher proportions of biofuel and additives, resulting in the formation of very small and stable water drops in the diesel fuel. This means it will require a new water separation technology.

Three-stage water separation protects injection system

If water enters the fuel circuit, it is reduced to small drops in the low-pressure fuel pump. After several fuel cycles, drop sizes smaller than 1/10th the diameter of a human hair are possible. MANN+HUMMEL has developed a solution for removing these very small and finely distributed water droplets from the diesel fuel. Fuel flows through the MANN-FILTER diesel fuel filter from the outside to the inside in three stages. This is referred to as pressure-side filter operation.

In the first stage, the filter medium reliably removes solid dirt particles from the diesel fuel. The second filter stage uses a coalescer fleece. It retains even the finest water droplets from the fuel/water emulsion and combines them to form much larger drops. In the third stage, a hydrophobic sieve ensures that the enlarged drops do not enter the injection system. Gravity causes the separated water to collect in a water collection chamber in the filter module. A sensor signals as soon as the water needs to be manually drained or siphoned.

The MANN-FILTER diesel fuel filter separates over 90% of water droplets from current petrol station diesel fuels, even in the case of tiny water droplets of up to 10 micrometers. It works right up to the end of the service interval, even with a loaded filter element. Both single-stage and two-stage concepts on the market achieve relatively low separation efficiency of up to a maximum of 35 – 40% and therefore do not provide reliable protection for modern injection systems.

Environmentally friendly

In conjunction with a prefilter, which protects the low-pressure pump, the fuel filter will be available from for the independent automotive aftermarket in 100% OE quality as the PU 12 010-2 z set for the Mercedes-Benz Actros, Heavy-Duty Engine Platform HDEP. Metal-free elements mean that the set is completely incinerable and therefore can be recycled to protect the environment.

A PreLine prefilter is currently in planning for regions whose fuel quality is affected by high particle and water contamination. This is mounted on the intake side and also operates with three-stage water separation to ensure optimal protection of the engine.

Service-friendly, patented concept when changing the filter

When the mechanic turns the cover during the removal of the filter, the retaining bracket of the element end plate will connect firmly with their mating parts in the cover. When unscrewing, this bayonet bracket ensures that the entire filter element releases and lifts up from the connection in the housing without the usual force. This makes removal in the workshop much easier. When installing the new filter element, it must be engaged by turning it slightly. The company has obtained patents in a number of countries for the filter element with bayonet bracket.

Martin Veit, Lead Product Engineer Fuel Filters Development in MANN+HUMMEL’s Automotive Aftermarket business unit, commented: “Whether corrosion or cavitation effects injectors, valves, or the CR-system high-pressure pump, this innovative separation technology greatly reduces damage that can result in system failure.”