With the hopeful arrival of some decent weather comes the anticipation of an influx of customers with air con issues.

The science behind air con is well known but perhaps misunderstood; lots of big expensive parts connected by pipes and wires. Compress these under the bonnet of a car and issues will no doubt arise.

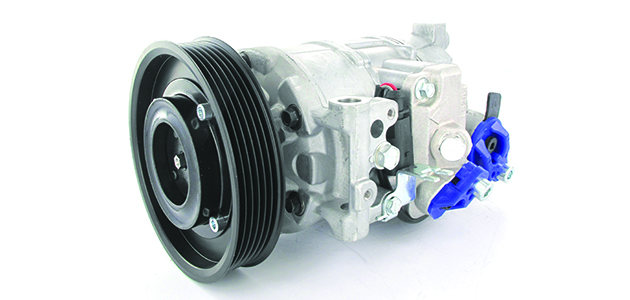

One of the most common fail components is the compressor, an engine driven pump used to compress gasses into fluids. Most modern cars have air conditioning and most modern air con systems are reliable to a level, but when things go wrong the compressor usually has a role in that failure. This is the time of year when most of the faults show, the air con is turned on after a “holiday” of two or three months.

Lubrication importance

A/C pumps are deceptively simple and have modest needs. One of the most obvious of these is lubrication, which often gets overlooked. The confusion comes with where the compressor gets its oil from. Most pumps that we come across use oil that is either contained in the pump or has an external supply from the engine’s oil (consider brake vacuum servo pumps).This seems somehow logical but the air con pump relies on oil that flows, internally, around the system. The oil does not stay in the compressor. This is as designed and normally it works fine.

The refrigerant takes a small portion of the lubricant as it moves through the system; this flowing of oil keeps the system working correctly. If the system has a leak or if an internal fault prevents this flow of lubricant, the compressor runs dry and ultimately fails. Air con leaks are relatively simple to diagnose, locate and fix but a considerable amount of oil can leak out in a very short time, causing a rapid and catastrophic failure.

If the compressor fails the result is often debris within the air con circuit which can cause issues when a new/replacement compressor is fitted and the debris isn’t addressed. Of course the new pump will suffer.

Don’t forget to flush

Flushing out the system is a must and particular attention should be made to “dual pass” systems, where one of the high pressure passages can be clean, giving the installer the perception that the system is clean, but the secondary circuit could be completely blocked. Correct installation of an in-line filter can help avoid this problem

Compressors are often supplied “virtually” dry; it is up to the installer to ensure the vehicle manufacturer’s recommendations are followed. If this is neglected once again, the new pump will fail.

Refrigerant level also has a bearing on the flow of the lubricant in the system. Too little and there will not be enough to “carry” the correct amount of lubricant round the system. If the system is overcharged the higher “head” pressure causes “pooling” in either the condenser or drier.

For more details on the FOURSEASONS range of air con products, including over 100 replacement compressor references, or to speak to our air con gurus for friendly help and advice telephone: 01527 835555 or visit www.4seasonsuk.com