Many vehicles nowadays incorporate a‘HBU1’ design wheel bearing; however, when this needs replacing some technicians still make a crucial error during the mounting process.

When installing the new bearing into the hub, the pressure is often misdirected and damage can either occur to the seal, or the rolling elements inside.

The most common complaint from the driver or the garage as a subsequent result of this error is ‘noise’. Because of the nature of this task, using the correct mounting tools is important when installing the bearing, and will significantly reduce these types of complaints and warranty claims in your garage.

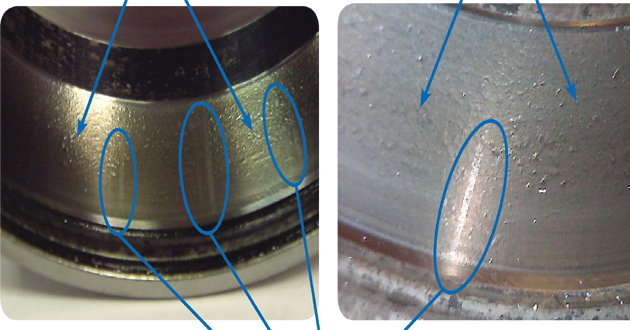

Common problems that occur tend to be as a result of the use of incorrect tools when mounting the bearing into its carrier. Contact is made with the seal or the inner ring, rather than the outer ring, resulting in the bearing not being pressed vertically into the knuckle. This then leads to water ingress into the bearing, misalignment of the rolling elements and flaking, which eventually leads to noise. (Fig 1 and Fig 2 below)

(Fig 1 and Fig 2): Samples of water ingress in a HBU1 type bearing (generic images – not VKBA 3496)

Examples

Examples of this type of fitment error are often seen when the bearing is returned under warranty – the following images highlight that pressure has been placed on the inner ring or seal during the installation of the bearing into the knuckle. (Fig 3 and Fig 4 below)

Metal impact points from the rolling elements (inner ring) Metal flakes from the rolling elements (outer ring)

Impact damage due to pressure being placed on the inner ring

Mounting the SKF VKBA 3496: Fitting Guidelines

1. Remove the old bearing from the steering knuckle.

2. Carefully clean the surface in the steering knuckle, and make sure there is no damage.

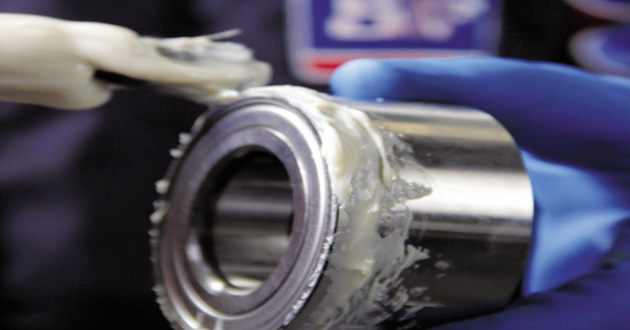

3. Apply a thin 3-5 mm coating of “Antifret Paste” (SKF LGAF3) to the circumference of the bearing outer ring. This paste must only be applied to the “ABS” magnetic sensor pick-up end of the bearing (do not apply to the magnetic sensor itself).

Caution: Bearings fitted with a magnetic ABS ring must be mounted the correct way around – the magnetic ring must face the ABS sensor.

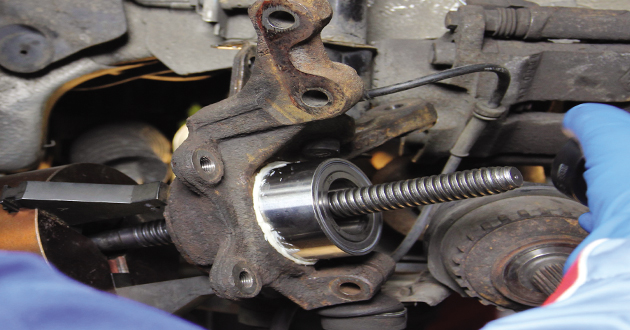

4. When installing the new HBU1 bearing into the knuckle, ensure that the paste/magnetic ABS sensor ring side is facing the ABS pickup sensor (if fitted). Apply equal pressure at 90˚, to the outer ring only, until the bearing is fully seated into the knuckle.

Under no circumstance should pressure be applied to the inner ring or seal, as doing so will damage the bearing. Then, install the clip rings if required for the particular vehicle application being repaired.

5. Always follow vehicle manufacturer’s fitting and torque recommendations when installing and tightening the components.

6. When pressing the drive flange into the bearing/knuckle assembly, pressure should only be applied to the inner ring. Again, any deviation from this will cause serious damage to the bearing!

NOT OK

OK

Note: Even though the VKBA 3496 bearing does not have a ‘magnetic sensor ring’, many other bearings do. Never use a screwdriver to test the bearings’ magnetic ring – use either a magnetic encoder detector or a paper clip.