Absolute Alignment outlines how garages need to approach wheel alignment procedures when using a two-post lift.

Absolute Alignment has been in the vanguard of wheel alignment equipment for many years, and recently has seen a huge rise in the use of its Bluetooth range on two-post lifts. As this opens up wheel alignment as a profit centre for workshops without dedicated four-post lifts, it’s important that the correct procedures are followed. To help, Absolute Alignment has produced this simple guide to two-post alignment best practice.

Step 1

Pre-check

This is common to all alignments, not just those using two-post lifts. In a busy workshop, it’s important that care is taken to ensure that there are no obvious problems with the vehicle that could cause an inaccurate reading. The checks include:

- Play in suspension bushes

- Visible damage

- Tyre pressures

Part of the pre-check should also be a scan for ADAS using a suitable diagnostic tool. The consequences of, for example, realigning the thrust angle and not checking the calibration of ADAS sensors could create problems. Alignment must be completed before ADAS calibration is carried out – a further profit opportunity for astute workshops.

Step 2

Prepare vehicle for adjustment

Some of the following is Absolute Alignment equipment-specific, but there are sure to be similar actions in other aligners.

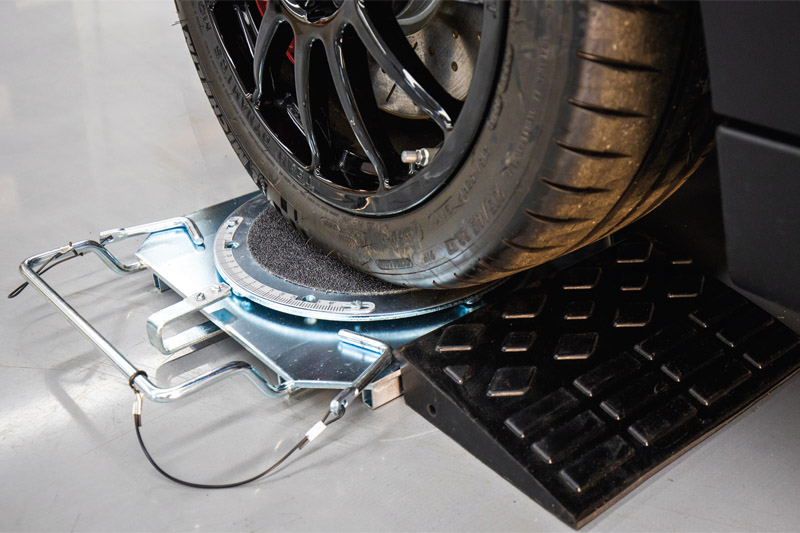

- Drive vehicle onto the front turn plates

- Select the vehicle from the database, or use a registration lookup like Absolute Alignment’s Shoot & Go option to save time

- Attach the 3-point Pro Wheel Clamps. These clamps avoid metal to metal contact, but care should still be taken to avoid damaging the rims

- Attach the alignment heads to the wheels

- Following the on-screen instructions, remove the locking pins from the turn plates and perform 10° caster swing from left to right – this gives the ‘before’ readings

- Start the engine whilst the steering wheel is straight – starting the engine is vital to balance the fluid in the power steering system ready for the next stage

- Switch off the engine and lock the steering wheel in the straight ahead position

- Freeze the readings and raise the vehicle to working height

- Add two-post drop brackets, ensuring they are absolutely level

- Continue up to the adjustment height

Step 3

Adjustment

- Unfreeze the readings – do not do this until the vehicle is at the full adjustment height

- Adjust until all figures are correct and within the manufacturer tolerance. This will show green on both the live adjustment screen and the full colour print out

- Note the preferred adjustment order:

- Rear axle first – camber then toe as available to adjust

- Front axle second – caster, camber then toe

- Refreeze the readings

- Drop the vehicle to the floor and remove the measuring heads and clamps

- Print the report and hand to the customer

Four-wheel alignment can be a new profit centre for many workshops, even if they don’t have access to a dedicated four-post alignment bay. A two-post lift is suitable for the task as long as professional help is sought when selecting the right equipment.