It is apparent from the Denso ‘TT Road Show’ that as an industry we have become reliant on our diagnostic tools to inform us of engine problems and analysis. While this is important, we should not forget that this, in many cases, is only an indicator and that the examination of the component we remove will aid a confirmation of the vehicle problem.

One of these is the spark plug, which is an indicator to the condition of the combustion chamber. Many technicians miss this by not removing the plug (mainly due to the longer duty cycle plugs used on modern vehicles), but with 70% of a spark plug’s ware being on the firing electrode, you should take the opportunity to reset the plug gap to the recommended setting. By doing this, you can see if the engine is running correctly (cold or hot) or whether the air/fuel mixture is correct (see examples below).

Early detection of problems will not only save your customers from a potential break down, but will also ensure that there is less stress on other key components like the coil pack. In turn this will also save money and the environment with better running and more efficient vehicles on our roads.

Late detection can also cause major problems and catastrophic failures, as shown in these examples:

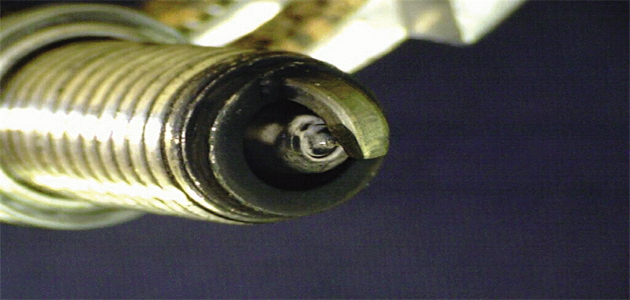

This plug indicates there is an air/fuel mixture problem. The carbon fouling around the plug would cause misfiring and poor combustion

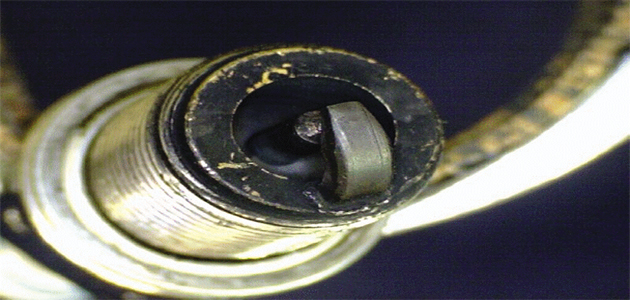

Over-torque at installation and poor air/fuel mixture has compromised the heat transfer of the plug. This has caused the centre electrode to swell and explode the ceramic insulator at the core, causing major engine damage

Good detection is the key to providing a complete service to your customers, saving them money and less stress. However it must never be forgotten that you should also take care when refitting spark plugs and use the correct process as defined by the manufacturer.