Over the summer, PMM was lucky enough to be invited to Schaeffler’s head offices in Minworth, Sutton-Coldfield, to receive one-to-one training from Master Technician and REPXPERT, Alistair Mason. Here’s what happened…

The day was to be split in two. First off, we were to learn about and discuss the function of a water (coolant) pump, the different varieties out there, its role in circulating coolant and its effects on engine temperature. Later on, we would move on to thermal management units and what their role is in the modern vehicle, but first things first: water pumps.

Part one: water pumps

For the sake of us layman editors, Alistair had geared his presentation to cover the basics and explain the different varieties of water pumps that exist. Judging by the slides Alistair was skipping over as he took us through a wealth of REPXPERT knowledge, it was quite clear that he had tailored his lecture for his audience of the day.

To provide a little bit of background, Alistair explained that the traditional mechanical water pump was in decline, mainly due to the pressures of emissions on the modern day power unit. In its place, there are now switchable pumps, e-pumps, and, of course, the thermal management unit. The principal difference between switchable and mechanical pumps is a shield that covers the impeller to control start coolant circulation when necessary. Otherwise, there would be a constant flow of coolant; a highly inefficient way of managing engine temperature.

To back up his teachings, Alistair had brought along an example of each type of water pump. This not only helped as a visual aid, but also enabled us to compare an OEquality INA pump with other options available in the market. Alistair also took this opportunity to talk about the use of plastic impellers and explained that plastic is becoming increasingly common, as it has a higher erosion tolerance than its metal counterpart, and it’s lighter and easier to manufacture to different specifications for engine needs.

After moving on to how e-pumps are another alternative from switchable, especially when it comes to stop-start vehicles and power saving, Alistair concluded by highlighting some of the most common repair and replacement errors he comes across: “By far the most common error I see in garages is the overuse of sealant when replacing a water pump. I cannot stress it enough when I say that the O-ring does not require sealant to ensure a secure fit. In fact, it will most likely compromise the fit and cause a headache further down the line.

“I would also recommend that the coolant pump is changed whenever the timing belt is replaced – the two practices should coincide.”

Part two: thermal management units

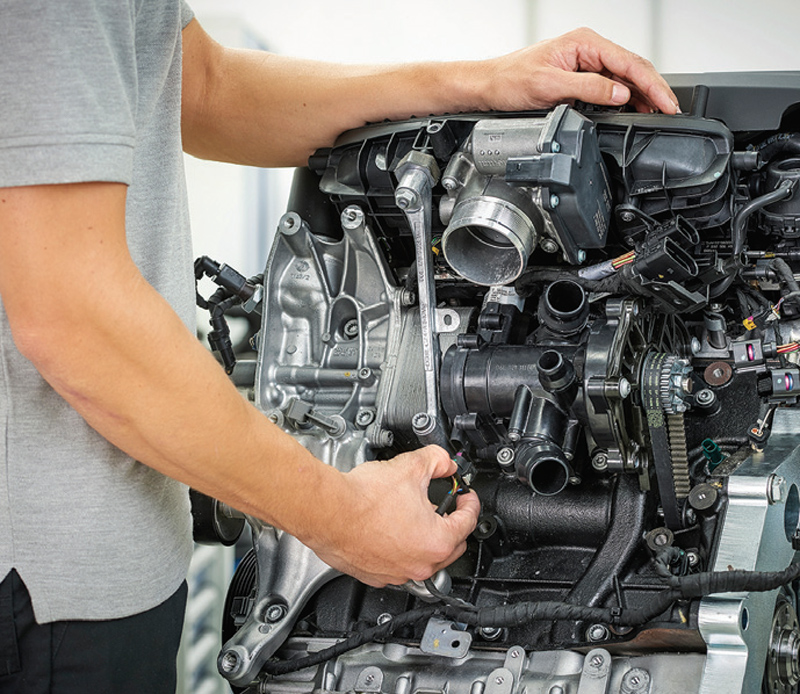

The lesson ramped up another level when Alistair moved on to the topic of thermal management units (TMUs). With an example to hand, he explained that the TMU enables the control of multiple areas of the cooling system. It allows for the engine to reach optimum temperature 30% faster, the interior heater temperature 30% faster, and the oil temperature for both the engine and the gearbox 50% faster.

To achieve this increase in efficiency, TMUs have a complex structure. Alistair explained that the essential features of the TMU are two rotary slides: “Rotary slide one controls the amount of cold coolant being introduced into the system. So, when an engine needs to be warmed up, rotary slide one will prevent any coolant from entering the system, and when it needs to be cooled, the rotary slide introduces small amounts of coolant to maintain the temperature. Rotary slide two controls the amount of flow and where it flows to, depending on the stage of engine operation.”

With the basic structure and operation of the TMU set out, Alistair then went through each stage of engine start-up and how the TMU reacts to temperature change. From initial start-up, when rotary slide one is shut to allow the engine temperature to rise, through to maintaining temperature at full throttle, Alistair went into detail on the temperature fluctuations at each stage, how the TMU responds to the needs of various components (i.e. the turbocharger), and the unit’s general functionality.

Much like the discussion on water pumps, the final part of this section was Alistair’s advice to technicians about TMU maintenance: “When replacing a TMU, it is crucial to remember to set it up using a diagnostic machine by inputting the basic settings into the unit. Should there be a problem that may be caused by the TMU, it’s always worth resetting the basic settings. I would also advise that when draining or refilling the system, use a diagnostic machine’s ‘vent mode’ to allow the coolant to drain and release any air that may be trapped.”

With that, Alistair concluded the training session. At first, it may seem like this level of technical detail is unnecessary to be able to carry out vehicle maintenance. However, what these Schaeffler REPXPERT classes enable is for you to truly understand why you are carrying out those procedures. With diagnostics being the name of the game, having this knowledge will help you establish a starting point in your diagnostic investigation.