With Pico technician Steve Smith zeroing in on the cause of excessive cabin vibration in a BMW 320D M Sport xDrive Touring, PMM picks up where we left off from April’s issue. Here’s what Steve uncovered…

Results

Based on the test results I had previously captured, I measured each alloy wheel, tyre radial and lateral run-out with an inexpensive tried and trusted dial gauge – a tool that has never seen such action since I started working with NVH. The following videos describe the measurement procedure and the offending results. The vehicle required immediate attention to be restored to driveability levels that were deemed acceptable for all parties involved.

As we can see from the left-hand front-wheel, which I chose to measure in the videos above, we identified considerable lateral and radial run-out of approximately 0.7mm and 1.45mm respectively. This would most certainly affect the radial run-out of the tyre as a direct consequence. I would like to add here that trying to find alloy wheel run-out specifications from an assortment of vehicle manufacturers has been challenging. A number of values have been discovered relating to a total run-out of 0.1mm, while others refer to the relationship between the hub centre and rim assembly. None, however, have specified the maximum run-out in terms of wheel span/rotation.

As you can see in the first video above, we captured 1.45mm of radial run-out across a very short wheel rotation (approximately 45°). If we were to exaggerate this for descriptive purposes, this could be compared to a ‘V’ indent in our desired perfect circle. A deformation like this would generate a firstorder tyre speed/frequency related vibration (FT1 and RT1) one disturbance per rotation of the wheel.

Further measurements confirmed a similar story for all the alloy wheels (including the alleged straightened wheels). We informed the customer. After trawling the internet, we found four used alloy wheels/tyres that were fully original and not refurbished. The seller of the used wheels/tyres gave us permission to visit and measure the run-out prior to purchase to ensure their authenticity. A word to the wise, this was not the first set of second hand/refurbished alloy wheels and tyres I had measured. While they look great, those I measured were more triangular than round! That is not to say that all refurbished alloy wheels are inferior, I just want those who commit to purchasing them to have their wits about them.

The good news here is that these secondhand wheels/tyres were confirmed as the original. The maximum radial run-out of all rims was approximately 0.3 mm (measured when mounted to a wheel balancer), and the included Star-rated tyres had not been removed from the wheels since new (it does not get any better when playing the second-hand game).

The wheels and tyres were then installed on the customer’s vehicle and we also measured the lateral and radial run-out prior to road testing.

As you can see in the videos above, we most certainly struck gold with these replacement wheel/tyre combinations. Ironically, prior to purchase, I had measured radial run-out of the rims on a wheel balancer and obtained 0.3mm, whereas when they were mounted to the vehicle, we achieved 0.15mm. This suggested that there was a run-out in the wheel balancer assembly.

Confirmation of repair

The proof is most certainly in the pudding, and confirmation of repair is often a procedure that is overlooked or sacrificed due to time constraints. Post-fix measurements provide further objective evidence that protects all parties involved and ensures confidence during the hand-over to the customer. Never has it been more important to qualify any repair we carry out than with complaints of noise or vibration. They are a matter of opinion, and without scientific measurements we are very much up against it.

When carrying out post-fix confirmation, make sure that all the variables are kept to a minimum; be sure to match the road/engine speeds between pre- and post-fix measurements and, where possible, measure along the same stretch of road with the vehicle driving modes set accordingly. These may include steering, suspension damping, transmission and stability modes.

I think we can agree that based on the video footage of the wheels/tyres and the data above, that we improved the cabin vibration level we attributed to first-order tyre vibrations (T1).

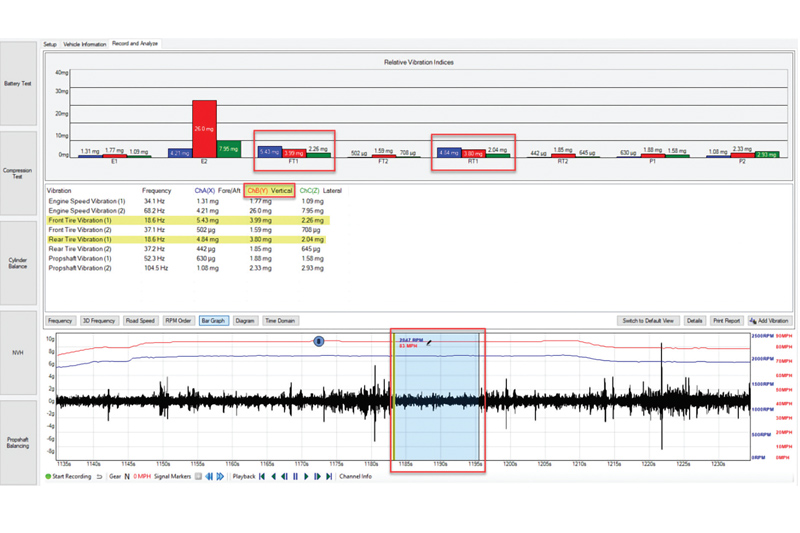

While I did not capture 4 x accelerometers at the key chassis locations post-fix, if we use the peak vertical axis measurement at the start of this study (18.3mg) and compare with our postfix values above (3.99mg), we have improved the vertical cabin vibration level at 83mph by over 75% (Fig 1, main image).

All parts fitted

Alloy wheel and tyre combination:

- BMW 19“403 M Sport Alloy Wheels (2 Front 8J x19 & 2 Rear x 8.5J x 19)

- 4 x Bridgestone Potenza S001 RFT (2 Front 225/40R19 & 2 Rear 255/35R19)

Additional comments

I mentioned earlier in this case study that I could only feel brake judder through the steering wheel, and not inherent cabin vibration at the sweet spot of 83mph.

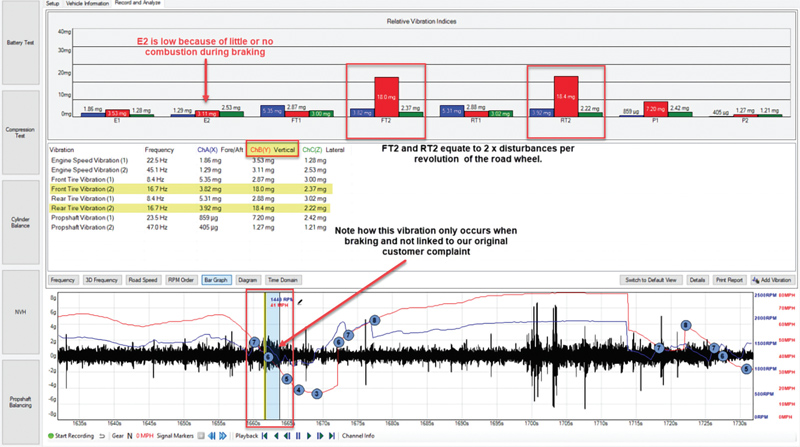

Looking at the data in Fig 2, we have captured a tyre speed/frequency second-order vibration (T2) which equates to two disturbances per revolution of the wheel when braking from high speed. While this was not our customer’s original complaint, I felt it necessary to report these findings, as the vibration level is identical to the original concern (approximately 18mg). By doing this we can avoid customer confusion and misinterpretation post-fix, while also protecting the integrity of our repair process.

Conclusion

No vehicle manufacturer produces an intentionally ‘bad car’. All vehicles are engineered to perform as intended and this includes wheel/tyre choice.

Working with multiple vehicle manufacturers, I have grown to accept the importance of ‘approved tyres’, especially or those vehicles that are finely tuned for performance. Such vehicles are designed with wheels and tyres at the forefront to ensure ‘feedback’ to the driver under all operating conditions.

This includes not only speed rating and rigidity, but shape and Radial Force Variation (RFV) from the highway to the countryside in all weather conditions. This is a lot to ask from a tyre and something the manufacturer has no control over (in terms of replacement) once the vehicle has been purchased. The temptation to install non-approved tyres is understandably high, but this comes at a cost!

The majority of problematic vibration cases I have come across have proved to be wheel and tyre related, and I would go so far as to say that they are the greatest offender.

Tyre manufacturers ensure that the best of their product achieves approval status for vehicle manufacturers (VM) and motorsport.

Thereafter, tyres that fall outside specified stringent tyre approval requirements are distributed accordingly. While these tyres are more than sufficient for their intended use, without VM approval we risk introducing variables, and diagnosis demands that all variables are kept to a minimum.

Wide section alloy wheels (some spanning over 22“) are vulnerable on roads today and the potential for deformation cannot be ignored given the forces involved as the vehicle hits a pothole. Remember the inner rim has no support other than the transfer of energy to the outer wheel spokes in the alloy assembly.