Why should shocks and struts be replaced in pairs on the same axle? Why should old mounting or protection kits be replaced? Why should you avoid taking shortcuts? To answer, here’s Monroe.

Shocks and struts should be replaced in pairs on the same axle, and that proper performance and service life depend on the corresponding installations of protection kits and, where applicable, mounting kits. Doing this helps promote better performance, longer product life and protects the interests of the vehicle owner.

Premature failure risk

Typically, shocks are subjected to more than 3,500 rebound compression cycles per mile. After 50,000 miles the shock has endured more than 175 million cycles. This means inevitable wear, affecting performance. The oil loses viscosity making the compression and rebound movements softer and less well controlled. The anti-friction band between the piston and the working chamber wears, allowing a certain amount of oil to pass through the gap, softening the shock and reducing control. If just one shock on that axle is replaced, one will be stiffer than the other, with the new unit quickly becoming overloaded as it tries to control all the rebound and compression efforts of the suspension. The new unit will quickly become damaged, losing oil and gas through the top seal, often as it overheats.

Monroe always recommends replacing shocks and struts in pairs on each axle and, in the case of struts, to fit them together with new Protection and Mounting Kits.

Mounting kits

Top mounting kits are subject to severe wear and tear. They are made of two fundamental parts: a rubber element, and a strut bearing that facilitates the rotation of the wheels while turning. Over time these elements wear out and must be replaced to ensure proper operation of the suspension and braking system.

If the mounting kits are in poor shape, they may cause a serious accident, particularly if the steering wheel becomes locked as it returns to the centre position after cornering. As the rubber element becomes harder over time, steering vibration and noise can soon be experienced. Their lifespan under normal driving conditions is approximately 50,000 miles, in line with that of the shock absorbers and struts. Monroe recommends that whenever shock absorbers or struts are replaced, new mounting kits should be fitted at the same time.

Protection kits

Protection kits are made of two essential parts. The first, the compression bumper, is made of a high-density polyurethane foam with a specific conical shape that becomes harder the more the unit is compressed. Placed on the top of the strut’s piston rod, its main task is to limit roll, dive and squat of the car’s body.

There are two main designs of the compression bumper:

- Some vehicles use a compression bumper attached to the lower part of the mounting kit. In this case the internal diameter of the bumper will be much bigger than the diameter of the shock absorber’s rod. Some installers think this an indication of a wrong part, but it is not.

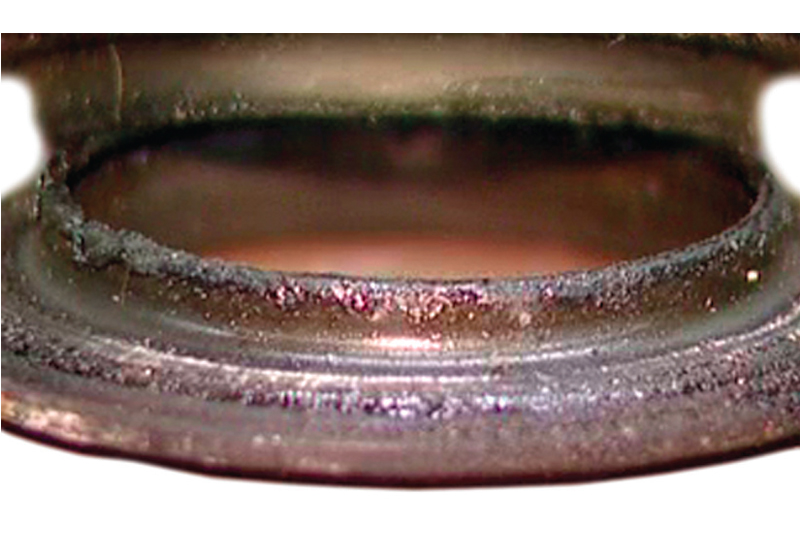

- Some vehicles have this element tightly covering the shock absorber’s rod. As it gets older, high-density polyurethane becomes porous and the internal diameter of the bumper becomes larger, loosening the fit over the rod. Inside the gap, abrasive particles can build up, and this can cause damage to the chromium coating of the rod leading to oil leakage. In addition, modern asphalt is often made from recycled tires which contain phosphorus. During the heat of summer, small asphalt particles transfer to the shock absorber’s rod, creating chromium phosphate crystals, a very hard substance with sharp edges which further damages the rod seal.

Normally the stroke of the shock absorber is around 4-5cm, but as the compression bumper degrades it can move as much as 12cm. This can result in unwanted body movements and can even lead to increased wear of springs and ball joints, in turn leading to poor steering control and reduced braking performance.

The second key element of the protection kit is the dust cover. Usually made of high-resistance rubber, it has the important task of protecting the shock absorber rod from contact with abrasive particles such as mud, salt, asphalt, water and dust that could irreversibly damage the chrome surface and cause the shock absorber to fail. It’s worth regularly inspecting the condition of each shock absorber by running a fingernail over the rod surface, as any burrs or scratches will be easy to spot.

Any imperfections in the rod surface can damage the shock absorber’s oil seal causing oil and gas to escape from the unit rendering it useless, especially if the shock absorber is pressurised.

The lifespan of protection kits can vary widely depending on the climate and how the vehicle is used, but as a rule Monroe recommends replacing them after 50,000 miles and always when the struts or shocks are replaced.