We recently had a starter motor returned to us under warranty that led to a fair bit of head scratching in our technical department.

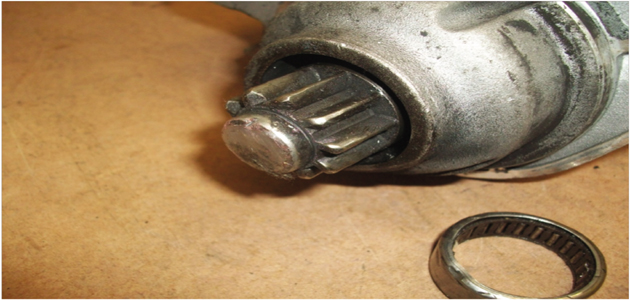

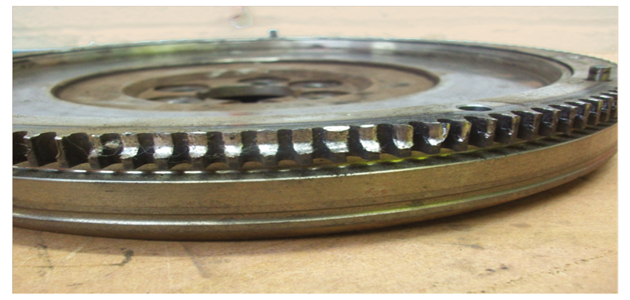

The front bearing was dislodged, while the pinion teeth showed signs of damage. Along with the starter motor, the customer had sent a damaged flywheel and clutch assembly, which he’d replaced as a consequence of the alleged starter motor failure.

By sheer coincidence, the original starter motor had also been returned back to us for surcharge credit. The complaint from the installer was that the bearing had fallen out, causing damage to the flywheel, and he was now claiming for consequential damages and labour.

The right diagnosis?

By looking at the images elsewhere on the page, it can clearly be seen that the flywheel was damaged whilst the original starter motor was still fitted, and, in fact, the original starter motor pinion had worn teeth.

Since the starter motor pinion material is softer than the flywheel, it is highly unlikely that the starter would ever damage the flywheel teeth. The reason for heavy wear in one position on the ring gear is because many engines stop at one of two points in their running cycle, hence the engagement of the starter on ignition often occurs in the same place over time, causing wear on the ring gear and subsequent damage to the starter pinion.

In this case, it would appear that the installer had not inspected the original unit and just fitted the replacement starter. A few days later, this failed – unsurprisingly – with the pinion bearing becoming dislodged as a consequence of the pinion teeth misalignment with the damaged flywheel ring gear.

In any event, the fault was obviously present prior to the replacement of the starter. The tricky aspect comes in the fact that the installer still made a claim under warranty and for consequential losses. As far as he was concerned, he had replaced the starter again and the fault had been cured. Crucially, however, he had also changed the flywheel and clutch assembly this time too!

A lesson learned

This scenario highlights the importance of carrying out a full diagnosis initially and looking for reasons why a component has failed. Inspection of the part removed from the vehicle can usually provide a good indication of the reason for failure, and the failure may well have occurred as a result of another problem elsewhere.

Full and thorough initial inspection of all parts related and proper diagnosis will save time and money for the installer, the motor factor and the manufacturer.

The evidence in pictures

Let’s take a look at the evidence that was presented to us:

This picture shows the replacement starter motor returned back under warranty.

This picture is of the damaged flywheel assembly. The damaged teeth can clearly be seen.

The picture here shows the original starter motor with damaged pinion teeth.

The final picture shows the original starter motor up to the damaged flywheel.