Josh Jones considers the opportunities and challenges posed by modern vehicle fault diagnosis.

With one of the many revolutions in vehicle technology being multiplexing and vehicle networking in general, has the process of diagnosing faults become easier or harder? I don’t know anyone that could answer that question if I’m honest. On the one hand, most modern cars have an ECM for almost every subsystem and each one of these will have its own integral trouble code list and a live data stream available, designed to help a technician in deciphering a fault quickly and efficiently. On the other hand, however, one of the main aims of digital vehicle networking – that of reducing the amount of wiring required to build a car – has been outweighed by the fact that there are now many more systems fitted to cars which have the effect of counteracting this reduction!

This obviously increases the amount of faults that can exist and a technician will potentially carry out more tests or analyse more data in order to reach a conclusion. Having said that, if multiplexing did not exist as an option you can imagine how heavy and bulky a wiring loom would be now. 20 years ago at the beginning of this major change, only the main vehicle systems would have had a data connection between them (engine, transmission, instrument panel etc.) and any other systems would have relied on individual connections to relay instructions/signals or provide power. If you encountered an electrical fault with a driver’s door window mechanism for instance, you would need to check through wiring diagrams and probably remove the door card to take readings in order to eliminate possible causes and reach a diagnosis, but you would not need to take into account that a fault could exist within a digital network that carries information from all the components in the door to the main body of the car and vice versa.

An example of such a fault was the 2010 Vauxhall Astra I recently took a look at for a friend of mine. The complaint was that the instrument display was sporadically highlighting ‘rear access open’ (or ‘the boot’ in plain English!) even with the tailgate firmly closed. This was causing some embarrassing situations at work with the alarm as you may imagine. Hopefully not a difficult one in the grand scheme of things I thought, but on inspection of the latch and associated wiring diagrams, it became clear that information from the position switch in the tailgate was transferred to the instrument binnacle via a vehicle network and not an individual wire connected to a bulb or buzzer like the good old days.

I know that it would be rare to encounter a vehicle that was much different in nature to this nowadays but I do think that the fact there is an extra piece of the puzzle to solve changed the way I had to tackle this fault. Initially, I checked that there were no bulletins available that might suggest a software fault could have been the cause, as this would potentially make any further physical inspection involving trim removal etc. completely futile. The fact that I even had to have this information available to me gives the task of diagnosis another dimension straight away as there are costs of keeping this database up to date and available.

Even if the vehicle had provided a trouble code relating to the described circuit from the multifunction control module (this is where the signal from the boot lid switch is sent to) the fault could still potentially have been a software glitch. There were no bulletins available to suggest an issue with the software for this system. After this, the fault was physically checked from the latch backwards in standard fashion. The boot latch switch itself operated OK, with the switch closing and opening fine when manually operated. The switch is provided with reference voltage from the multifunction control module and the circuit continues after the switch, to an earth point under the rear lamp cluster but its way there is connected by a multi plug, which in the case of this particular vehicle was suffering from a poor connection at the time.

This is easily resolvable in under an hour. I was grateful of this – as we all are when fault-finding – as if the problem needed to be traced further down the line and investigation was required into the link between the multifunction control unit and the instrument cluster where the warning was being displayed, a very different diagnosis skill-set and process would need to be used. I would have had to put down my multimeter and pick up my oscilloscope to establish first the integrity of the link and, if needed, I would have had to establish if the signals being transferred on the network that carried info relevant to the boot switch operation were not corrupted in any way and that the correct programming had been carried out.

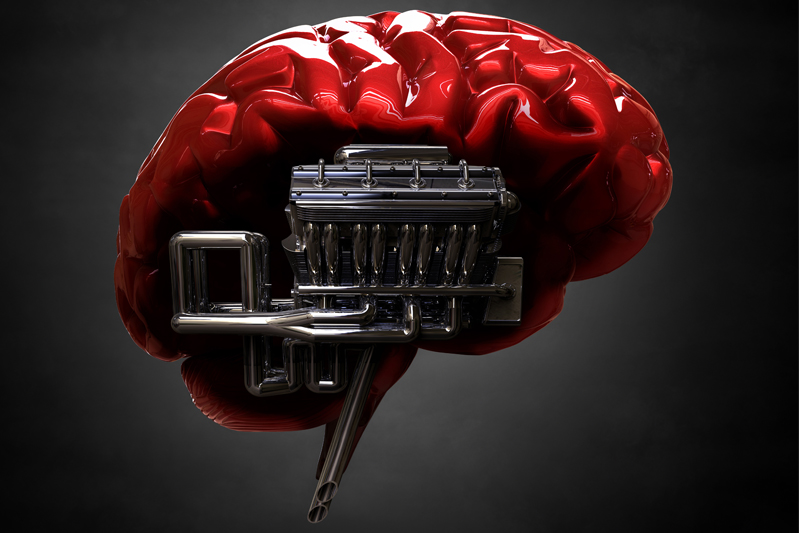

The point I am trying to make is that we are getting to a point in vehicle development where year after year there is an increase in the percentage of signals, information and instructions sent and received across a vehicle electrical system. We are witnessing electrics become electronics. Although this may make solving problems more information and equipment intensive, any technician that is able to recognise an electronic or ‘mental health’ fault as the cause of an issue as opposed to an electrical or ‘physical fault’ will have a much easier job in the workshop, providing all of the information required is available. Much like recent progress in understanding mental health issues in people, there is a similar movement in vehicle repair where technicians will need to be able to interpret information in cars’ brains!