If coolant leak, as a result of manifold ‘warping’, is causing an issue then this repair solution could be your answer.

THE PROBLEM

A common problem on the 800cc Daewoo/Chevrolet Matiz is corrosion to the alloy cylinder head and distortion (warping) of the plastic inlet manifold, resulting in a coolant leak between the two. The plastic inlet manifold on this three cylinder engine includes a ‘blanking plate’ moulded to the end which seals against a water-way on the cylinder head. Over time the plastic deteriorates, eventually resulting in a coolant leak.

THE SOLUTION

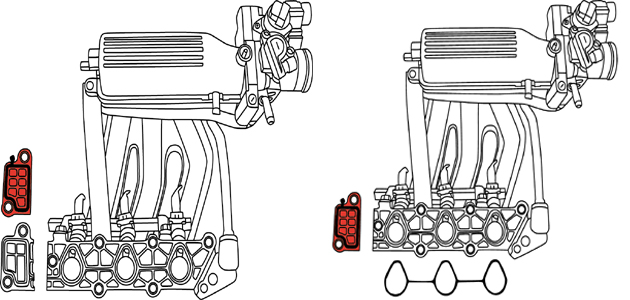

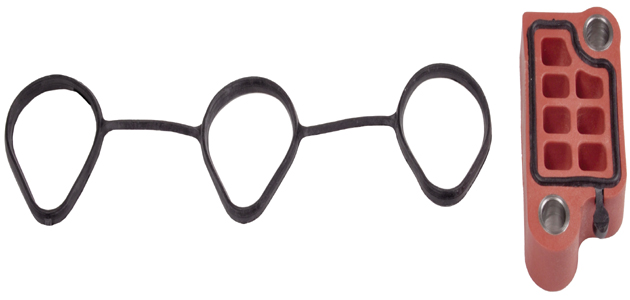

ADG06290 is an inlet manifold repair kit to give a long term cure to this particular problem, comprising of a high quality blanking plate and modified manifold gasket. Carrying out the modification is straightforward and involves three fairly simple steps (shown below).

REPAIR TIME

Manifold replacement = 1.2 hours, plus allow a further 20-30 minutes for modification.

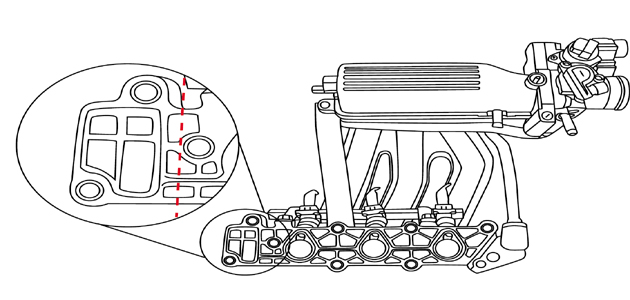

1. Once removed from the car, hold or carefully clamp the plastic inlet manifold. Mark the coolant blanking section of the manifold that you are about to saw through, making sure that you mark a section slightly larger than the size of the new blanking plate. This is to ensure there is no interference between the manifold and new blanking plate when they are fitted to the engine. Check twice– cut once! (Fig 1 below)

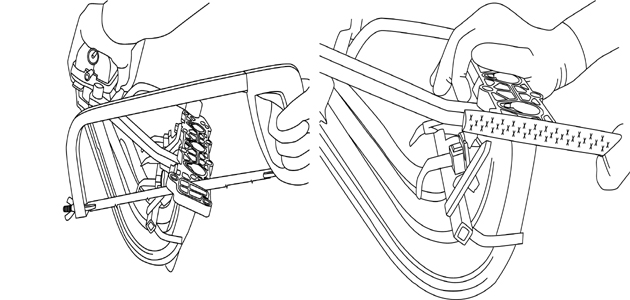

2a and 2b. Plug the three outlet ports to prevent debris falling into the manifold. Carefully saw through the manifold and remove the old blanking section. Then, trim/file the rough edges of the manifold to ensure a flat mating surface is maintained and clean as necessary (Fig 2a and 2b below).

3a and 3b. Ensure that the mating surface of the cylinder head is clean and refit the manifold using the new manifold gasket supplied. Fit the new blanking plate onto the cylinder head, using a little RTV if required. Tighten all manifold nuts to the manufacturer’s specifications (15-19Nm) (Fig 3a and 3b below)