Increase in power over the whole speed range, low fuel consumption, improved engine efficiency, reduction of emission values, less thermal stress for the engine – there are numerous reasons to cool the combustion air of supercharged engines with intercoolers. Basically, a distinction must be made between two types of cooling:

Direct charge air cooling

An intercooler is installed in the vehicle front-end area and is cooled by environmental air (wind blast).

Indirect charge air cooling

Coolant flows through the intercooler and discharges heat.

Structure/function

In terms of structural design, the intercooler corresponds to the coolant radiator. In the case of an intercooler, the medium to be cooled down is not coolant, but rather compressed hot air (up to 150°C) coming from the turbocharger. Basically, heat can be withdrawn from the charge air by outside air or the engine coolant.

The charge air enters the intercooler and, in the case of direct charge air cooling, has the wind blast flow through it. It has then cooled down by the time it reaches the engine intake tract. In the case of a coolant-cooled intercooler, the cooler can be installed in almost any position, with the smaller design volume representing a great advantage.

Thus, for example, in the case of indirect charge air cooling, the coolant-cooled intercooler and the intake tract can form one unit. Without an additional cooling circuit, however, the charge air can only be reduced to near the coolant temperature.

With the aid of a separate intercooler coolant circuit, independent of the engine coolant circuit, the efficiency of the engine can be further increased by increasing the air density. A low-temperature coolant radiator and a charge air coolant radiator are integrated in this circuit. The waste heat from the charge air is first transferred to the coolant and then dissipated to the environmental air in the low-temperature coolant radiator.

The low-temperature radiator is housed in the vehicle front-end. Since the low-temperature radiator requires significantly less space than a conventional air-cooled intercooler, this solution creates free space in the front-end. In addition, the voluminous charge air lines aren’t required.

How to correctly replace an Intercooler

1. The customer complains that his engine performance has deteriorated after an accident.

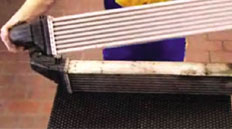

2. The vehicle is examined and it’s established that the charge air cooler is damaged.

3. To remove the charge air cooler, unscrew the two quick release locks and remove the charge air lines.

4. Lever out the holders of the charge air cooler and remove the entire part.

5. Clean the connections of the charge air lines and replace the sealing rings.

6. Before installing the new part, compare it with the old one.

7. Also check the new charge air cooler for damage.

8. You can now install the new charge air cooler.

9. When positioning it, ensure that it sits correctly – the holders should click into place audibly.

10. Reconnect the two charge air lines and click the quick release locks.

11. The charging pressure should be tested using a diagnosis device and compared with the specifications of the manufacturer.