REPXPERT’s Alistair Mason replaced the clutch and dual mass flywheel (DMF) on a 2008 Land Rover Freelander 2 TD4, fitted with a 2.2 TDI engine and which had covered more than 133,000 miles.

Following complaints that the vehicle’s clutch was ‘slipping’, a short road test diagnosed the problem and confirmed that the clutch needed to be replaced. Prior to starting the repair, ensure the vehicle’s locking wheel nut key is nearby.

Step-by-step procedure

With the vehicle positioned on the lift, open the bonnet, remove the battery, battery carrier and air filter assembly (see below) – this gives good access to the top of the gearbox.

Disconnect the gear cables, clamp the flexible part of the hydraulic clutch pipe and then detach the clutch pipe from the concentric slave cylinder connection. Remove the electrical multi-plugs from the front of the gearbox and stow in a safe area. With the vehicle still on the ground, slacken the O/S/F hub nut, as the driveshaft has to be removed later in the process, and slacken both front locking wheel nuts. Raise the vehicle lift to waist height, remove both front wheels, release both front flexible brake pipes (see below) and ABS wiring looms from the retaining brackets, and disconnect both inner wing panels to expose the gearbox and the engine.

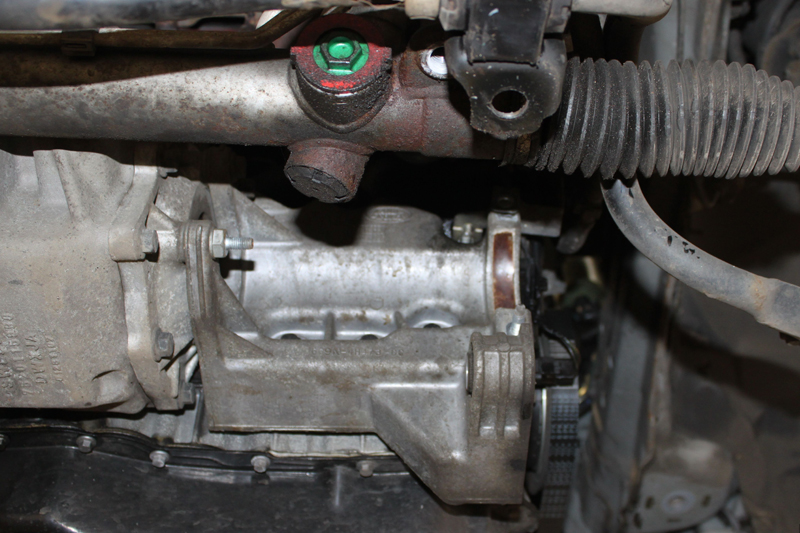

Raise the vehicle lift to gain access to the underside of the vehicle and remove the engine undertray. The front sub-frame assembly then needs to be detached. This is achieved firstly by securing the steering rack in position. During this particular repair, this was accomplished by strapping it to the front struts and disconnecting both front ball joints from the hub carriers.

Now take off the exhaust mounting, which is located at the rear of the sub-frame (see below), before removing the mounting bolts for the anti-roll bar and steering rack.

Support the sub-frame using a transmission jack, unscrew the four sub-frame retaining bolts and lower the sub-frame on the transmission jack. A second person may be required to assist in the sub-frame removal.

Drain the gearbox oil and transfer box oil. Whilst the oil is draining, remove the turbo intake pipe that runs under the engine and then remove both front driveshafts from the gearbox. The N/S/F driveshaft can stay attached to the hub assembly and secured to give clearance (see below).

The O/S/F driveshaft needs to be removed from the vehicle. At this stage, refit the drain plugs and torque to the manufacturer’s specification. With the O/S/F driveshaft removed, remove the centre bearing carrier bracket (see below) from the transfer box and engine.

Disconnect the prop shaft flange from the transfer box. It is always advisable to mark the flange location position prior to removal to avoid any balance-related issues after the repair, and then remove the breather pipe from the vent on the top of the transfer box.

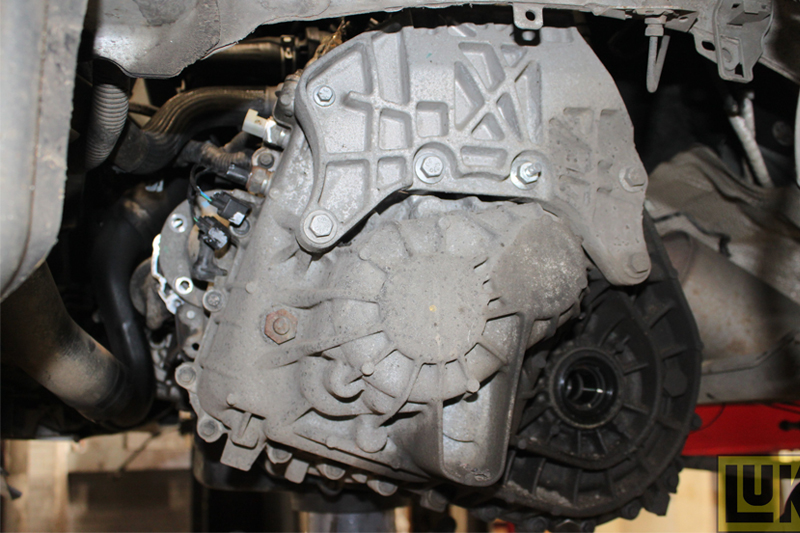

Remove the seven retaining bolts and the transfer box from the gearbox, then stow in a safe area (see below).

Detach the bell housing bolts, leaving in an easily accessible bolt to retain the gearbox in position, before supporting the engine using either an engine beam or a second transmission jack. Remove the upper gearbox mounting and then lower the engine to aid in the gearbox removal.

Take away the earth strap connected to the gearbox mounting bolt, as well as the mounting assembly (see below).

Support the gearbox with the transmission jack, remove the final bell housing bolt and then ease the gearbox away from the engine. Once clear of the clutch assembly, lower the transmission jack and clear the gearbox, placing it in a safe area.

With the gearbox out of the way, remove the clutch assembly from the flywheel. During this particular examination, it was clear to see that the clutch plate had reached the end of its service life, as it had worn close to the friction material rivets.

Replacing the DMF

The DMF was replaced upon the customer’s request, and in this instance, excess heat was evident due to the ‘blueing’ on the flywheel face. The replacement process is as follows: remove the DMF, check for any leaks on the back of the engine and rectify as required, so as not to contaminate the new clutch components. Then clean the back of the engine with brake and clutch dust cleaner, ensure the new flywheel locates correctly, secure into position with the new flywheel bolts, and torque to the manufacturer’s specification. Flywheel bolt replacement information and torque values can be easily obtained from Schaeffler’s REPXPERT workshop information portal or Schaeffler’s DMF Checkpoint app.

Clean the bell housing area with brake and clutch dust cleaner, unclip and withdraw the concentric slave cylinder adaptor/extension pipe, and then remove the concentric slave cylinder (CSC). Ensure the CSC mounting surface is clean before installing the new CSC, then torque the retaining bolt and fit the new adaptor/extension pipe.

Smear a small amount of high melting point grease on the input shaft splines and slide the new clutch plate onto the input shaft. Doing this will guarantee that the clutch plate has the correct splines while also distributing the grease evenly. Remove the clutch plate and any excess grease.

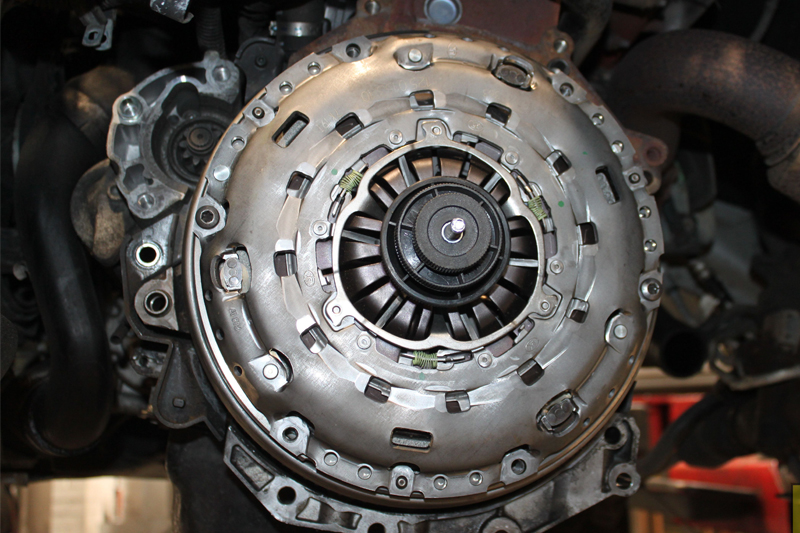

Mount the new clutch assembly onto the flywheel using a clutch alignment tool (see below), and confirm the clutch plate is fitted correctly with either ‘Gearbox Side’ or ‘Getriebe Seite’ facing the gearbox, and that all the clutch faces are clean. When installing the clutch bolts, tighten and torque them evenly and sequentially.

It is always best practice to flush/change the clutch hydraulic fluid when replacing the CSC, and this is done simply by removing the clamp from the hydraulic clutch pipe and flushing the fluid through into a drainer until the clean fluid is running through. Once flushed, clamp the hydraulic pipe ready for the gearbox installation. Finally, ensure the engine to gearbox alignment dowels are installed in the engine before installing the gearbox.

Place the gearbox on the transmission jack and ease into position. It is always worth spending a little time to ensure the gearbox is at the correct height and angle on the jack to help with installation. Once the gearbox is located correctly, secure with an easily accessible bell housing bolt and then install in the reverse order of removal.

Remember to refill the gearbox and transfer box with the correct quality and quantity of oil and to reset electrical systems and control units when the battery lead has been reconnected. A final road test will ensure a quality repair.