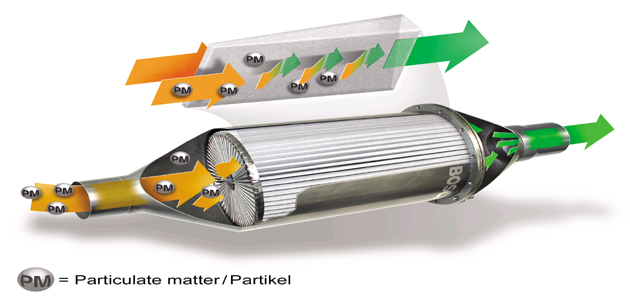

Achieving the tough vehicle emissions levels under Euro 5 legislation requires a Diesel Particulate Filter (DPF) to be fitted to collect carbon soot particles generated from the combustion process in a diesel engine.

These particles are microscopic balls of carbon containing pure carbon at their core, which are deposits of different hydrocarbon compounds, metal oxides and sulphur – some of which are potentially hazardous to health.

DPFs, however, are prone to malfunctioning as a result of becoming blocked or full, particularly when the vehicle makes an excessive number of short journeys.

This will result in a fault code appearing (see list of typical DPF fault codes at the bottom of the article), such as ‘P1471 – DPF regeneration not completed’. When this happens, the first response is to try running a regeneration of the filter to see if that solves the problem.

Regeneration variants

Forced regeneration is a simple procedure that can be carried out by a workshop and is usually needed because an active regeneration has not been successful during every day driving by the driver. Depending on the type of diagnostic programme available, this can either be a ‘Static Regeneration’ or a ‘Regeneration Run’.

For this example, we’ll be using the Bosch KTS diagnostic tool as our diagnostic unit of choice.

Static Regeneration procedure

To carry out a Static Regeneration, the vehicle is normally positioned outdoors on a suitable surface and the regeneration is initiated and controlled by the KTS. Strict safety procedures must be observed prior to and during this process.

For a Regeneration Run, the technician must select the programme on the KTS and take the vehicle for a drive at a moderate cruising speed for a suitable period of time – usually about 20 minutes. The KTS initiates the Regeneration Run and monitors the process throughout, so a second person is required to operate the KTS while this is being performed.

Further training

Bosch runs a half day training course (VSD 36) for technicians who wish to effectively diagnose faults with DPFs. The course covers the design and function of a DPF, and what conditions might cause the DPF to block prematurely, giving the technician background information on DPFs before covering the different types of regeneration strategies.

Typical DPF Fault Codes

P1471 – Diesel Particulate Filter (Bank 1) Regeneration not completed

P2002 – Diesel Particulate Filter (Bank 1) Efficiency below threshold

P2003 – Diesel Particulate Filter (Bank 1) Particulate mass too high

P242F – Diesel Particulate Filter (Bank 1) Regeneration not active

P244A – Particulate Filter DIfferential pressure too low

P244B – Particulate Filter Differential pressure too high

P2452 – Particulate Filter Differential pressure sensor malfunction

P2453 – Diesel Particulate Filter Differential pressure sensor malfunction

P2454 – Diesel Particulate Filter Differential pressure sensor voltage too low

P2455 – Diesel Particulate Filter Differential pressure sensor malfunction

P2458 – Particulate Filter regeneration maximum regeneration time exceeded

P2459 – Particulate Filter regeneration, regeneration frequency implausible