Phil Wilson from BTN Turbo explains how the increasingly complex technology built into turbochargers is essential in helping vehicle manufacturers cut emissions for diesel engines, without compromising power.

One of the routes to greater efficiency is to combine two, three or even four turbos, which use low pressure and high pressure forced induction to precisely match engine speeds and loads. These units were previously only used on performance cars, but are now being used on standard vehicles, so you may see them in your workshop before long, if you haven’t already.

Two-stage turbocharging

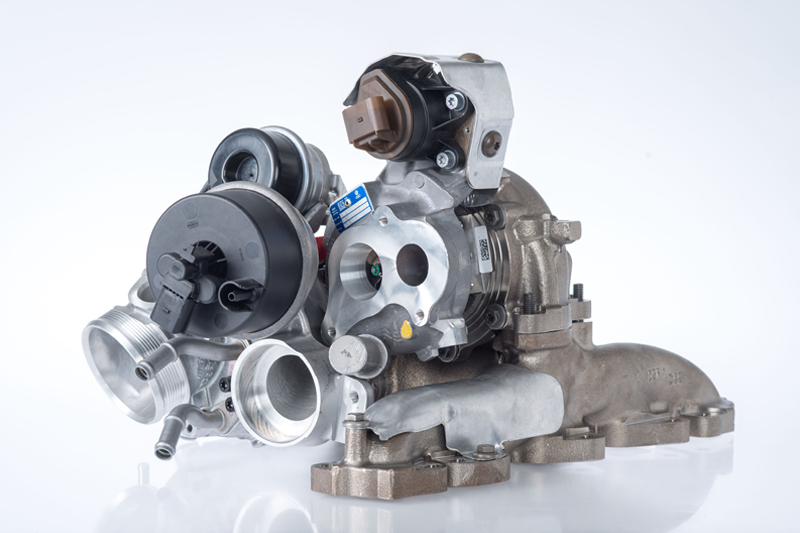

BorgWarner’s two-stage R2S turbochargers are used on Volkswagen’s 2L turbo diesels, connecting two turbos in series. At lower engine speeds, exhaust gases drive a small, high-pressure variable turbine geometry (HP VTG) turbo. As engine revs build to medium speeds, this turbo’s wastegate opens to supply a larger, water-cooled turbo optimised for low-pressure exhaust gas recirculation (LP EGR). The exhaust gases are enriched with fresh air, feeding the LP turbo’s compressor.

As engine speeds increase further, a bypass valve cuts the supply to the smaller HP turbo and the larger LP turbo takes over. Although some exhaust gases keep the small turbo spinning, the large turbo now provides all the charged air pressure.

This system improves response, with almost instant acceleration at lower engine speeds, more consistent delivery at higher speeds, and more efficient, cleaner combustion throughout.

A step further: the triple turbo

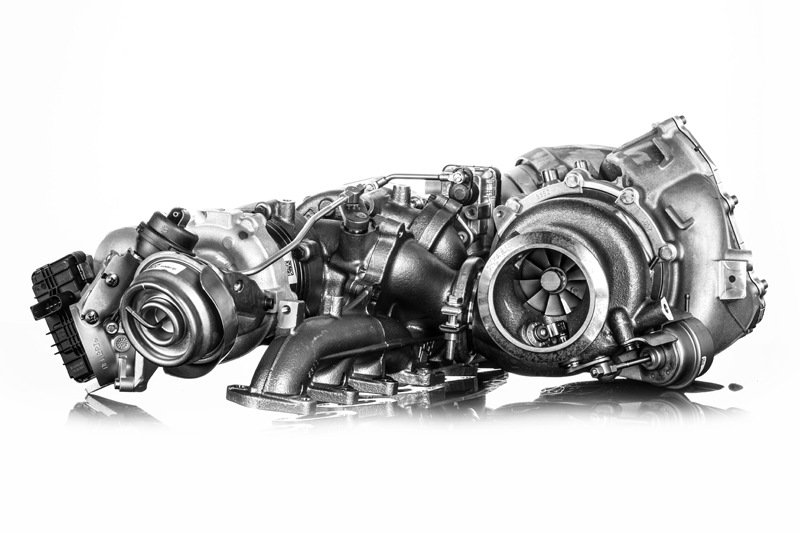

For its R3S turbochargers (used in BMW’s M-Performance 3L diesel engines), BorgWarner combines two electrically- controlled VTG HP turbos with one wastegate-controlled LP turbo.

In this triple turbo, the individual units come into play sequentially. At lower revs, just the first HP turbo operates, providing immediate charge air pressure for optimum dynamic response. As engine speed and loads increase, intake air enters the large LP turbo and gradually this turbo’s wastegate opens, allowing exhaust gases to drive the second HP turbo, reaching maximum charge air pressure.

The benefits of the extra turbo are dramatic. When fitted to the same 3L diesel engine, the R3S triple turbo produces 25% more performance and 8% lower fuel consumption compared to the R2S two-stage turbo.

The quad turbo

BorgWarner’s quad turbo is fitted to the BMW six-cylinder diesels used in the 750d XDrive, 5 Series, X5, X6 and X7 models. Based on the same principle as the R2S, it has two HP turbos, plus two smaller LP turbos.

The first HP turbo quickly generates charged air pressure without turbo lag. As engine speeds increase, the LP turbos come on stream, with both smaller units working together. At higher speeds, the final HP turbo is introduced for maximum output. This approach produces an even faster response from the turbos, providing extra power and a smooth torque curve, without increasing the system’s weight.

Keeping diesel relevant

These are complex systems. Impressive gains in efficiency are balanced with lower emissions, helping to keep diesel engines competitive at a time when many purchasers are moving away to petrol, hybrid or electric power.

The complicated nature of these turbos, particularly the precise operation of their VTG, wastegate and bypass valves, means they require specialist knowledge from turbocharger experts. As these complex turbos appear in your workshop, you can rely on BTN Turbo to provide the technical know- how that this technology demands.