Problems in the market persist with the failure of the belt tensioner on the 1.7 litre turbo diesel engine used in many Vauxhall/Opel and Isuzu vehicles following the prescribed belt and tensioner change specified by the vehicle’s official service schedule.

The issue is further complicated, as there are at least 10 versions of this unit, each with its own design variant; however, the cause of the most common failure occurs because the belt is over-tensioned which, because of its design, is very easy for the technician installing the belt to do. Fear not, though, as this is equally easy to avoid if the correct fitting procedure is followed.

Warranty rejection

It is essential that workshops undertaking this repair understand that the failure is rarely a product quality issue, so a warranty claim for this problem will almost certainly be rejected.

In the overwhelming majority of cases, the cause of the failure is as a direct result of the incorrect installation of the new belt and tensioner, so workshops must ensure that technicians tasked with the repair follow all of the technical guidelines.

The reason that the belt can become over-tight is because, although, it is straightforward to install the new spring loaded tensioner, it is also very easy for it to move while it is being secured; just a small movement can make a big difference to the tension on the belt.

To demonstrate the extent of this phenomenon, if during its tightening the tensioner moves by only 4 or 5˚, the tension on the belt will increase threefold from the 20kg it is designed for to a catastrophic 60kg+. This then causes the tensioner to wear excessively and ultimately, distort and fail.

Quality replacement

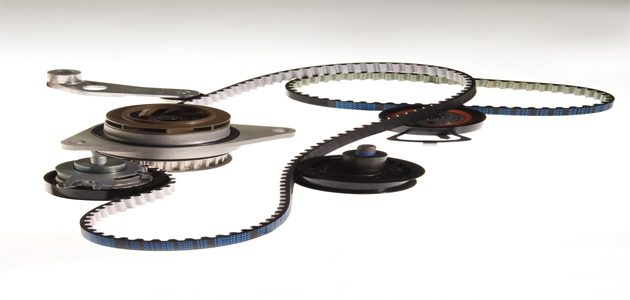

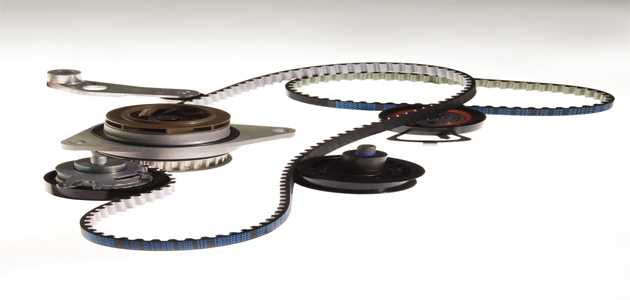

Depending on the variant, Dayco provides either timing belt kit KTB414 or KTB468 for the GM 1.7 turbo diesel engine, but both options contain a High Tenacity (HT) or ‘white’ belt. The Dayco HT belt has become an OE solution for an increasing number of vehicle manufacturers. As a result, more vehicles fitted with these white belts are appearing in the workshop.

The fitting procedure

Dayco recommends that technicians follow its published fitting procedure, designated for the specific engine code, as well as making sure that they tighten the bolt to the manufacturer’s specified tension, which is also stated by engine code in the Dayco technical sheet.

This is particularly important, as it seems more than a coincidence that the most common failures tend to occur on the Z17DTH and Z17DTL units, which both feature tensioners that have a lower torque setting than the majority of the other engine codes.

The precise detail of the fitting procedures differ according to the engine code, but to set an accurate belt tension the engine must be cold and should have been at rest for at least four hours. Procedures common to all models are then as follows:

1. The TDC locking bolts must be installed in the camshaft sprocket and the high-pressure pump sprocket. The lug on the crankshaft pulley must be in line with the lug on the oil pump cover.

2. Observe the direction of engine rotation. The timing belt must be installed and tensioned following the arrows in a clockwise direction and starting from the crankshaft, oil pump, fuel pump, camshaft and tensioner pulley.

3. Not all engine codes need this step, but Z17DTH and Z17DTL units require the TDC bolts to be removed and the crankshaft rotated 60° in the direction of engine rotation.

4. Tighten the tensioner bolt to the vehicle manufacturer’s specified torque for the engine code in question, making sure the tensioner does not move during this operation. It is advised to make a reference point to make sure the tensioner has not moved.

5. Depending on the engine code, the crankshaft must be rotated between two and six revolutions in the direction of engine rotation to the adjustment position.

6. The lug on the crankshaft must then be in line with the lug on the oil pump cover.

7. Reinstall the TDC bolts to the camshaft and fuel pump sprockets. If it is not possible to install these freely then the tension procedure must be repeated. To simplify the process further, technicians can use a Dayco Tensiometer, which will ensure the correct tension is achieved. The tool is easy to use and just needs the relevant test code for the belt application to be entered and the belt vibrated. If the test reading is ‘OK’ the belt is fine, but if the result reads ‘+ or – 3’, the belt will need to be reset.