First Line considers the role of the suspension bush and why it should not be overlooked.

Although they may look insignificant and be the least expensive part of a vehicle’s steering and suspension system, bushes are crucial to a car’s correct handling and overall safety. This is particularly prevalent for the bushes that are used in suspension arms, which will also have a huge effect on the longevity of the complete unit.

Choose carefully

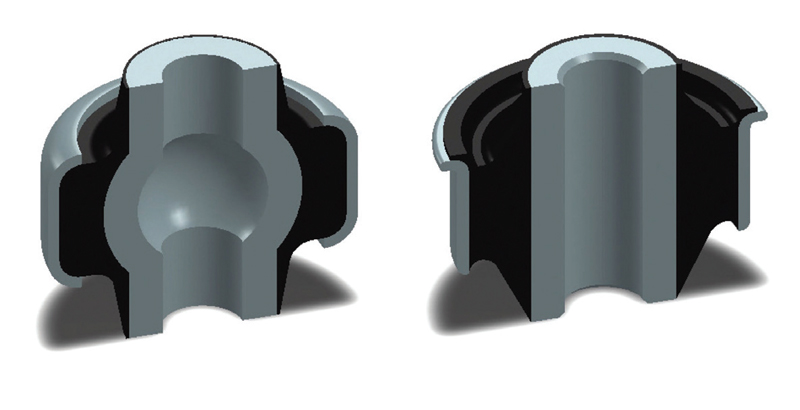

Unfortunately, there are bushes in the aftermarket that are of a non-OE standard and these sometimes use a straight, rather than the OE standard swaged tube in their construction, and are, therefore, cheaper.

The difference between the two is that a swaged tube provides a greater bonding area for the rubber, which directly increases the longevity of the bush. Although swaging is an extra step in the manufacturing process, the benefits of this process are plain to see when the cheaper bush fails earlier than it should.

If a replacement bush is poorly manufactured, or produced to an inadequate specification, it is highly likely that it will not possess the correct shore hardness or noise vibration harshness properties required. Subsequently, this will have an adverse effect on handling performance/ride quality, and could result in the vehicle pulling or lurching in one direction or the other when driven. Even if low quality bushes are replaced as a pair, the vehicle will still not perform as it is designed to, and it is likely to feel dull and unresponsive to the driver.

Therefore, it is vital that the bushes are installed correctly. On many occasions, the First Line technical team have encountered wishbones that has been returned due to the bushes failing prematurely, often as a direct result of incorrect fitment. It is important to remember that this replacement process requires specialist equipment – an aspect to the procedure that can be overlooked.

Best practice

When it comes to its installation, a wishbone should only have its fitting bolts tightened when the vehicle’s wheels and axles are in their normal ride height position, not when the wheels are in an unloaded ‘hanging’ position. Tightening them without load will put a torque reaction on the bushes when the vehicle is taken off the service ramp, which will lead to the centre of the wishbone bush being ripped away.

Ultimately, it is important to follow the OEM procedure for any replacement, as some elements will vary from vehicle to vehicle. Following any steering and suspension component replacement, you should carry out a full wheel alignment check, and where applicable, a steering angle sensor reset. For vehicles with ADAS technology, following a vehicle alignment check, the system may need recalibration, but again, refer to the individual OEM procedure for the vehicle being worked on for full details.