BorgWarner outlines the key components of the range it offers to aftermarket businesses, including its vital remanufactured products.

With electric motors, power transmission technologies, power electronics and thermal management products available, BorgWarner’s portfolio aims to serve the growing market of electric and hybrid vehicles. As a technology partner, the supplier is supporting the automotive industry as the face of mobility transforms itself completely. This also applies to the aftermarket: With the ongoing electrification of the automotive industry, BorgWarner’s products will find their way into workshops as spare parts.

The amount of electrically driven vehicles is continuously growing. New technologies and products are conquering the market. These developments also impact the aftermarket. To navigate this transition, trade and workshops now more than ever need an experienced and technologically competent partner with profound know-how by their side. With its own product developments and strategic acquisitions in the electrification space, BorgWarner is well-positioned for this role, as one of the world’s leading specialists in powertrain technologies for combustion engines, as well as hybrid and electric vehicles. In close collaboration with vehicle manufacturers, the company develops and produces powertrain solutions for electric vehicles that will also be available for the aftermarket in the future. This allows trade and workshops to secure their growth potential in a timely manner.

In the area of exhaust gas recirculation, BorgWarner produces all EGR components inhouse, which allows the company to develop and produce complete systems. Modules, valves, and coolers serve as highly efficient solutions for reducing fuel consumption and the associated CO2 emissions. Furthermore, BorgWarner’s product portfolio for all-wheel drive clutches provides optimal support for vehicle servicing with special repair kits. In the area of thermal management, BorgWarner offers efficient solutions with components and modules for air flow and coolant management. The flow control products contribute to reduced fuel consumption and increase user comfort through precise temperature management of the powertrain systems. All products are validated by leading OEMs and meet current emission standards such as Euro 6.

BorgWarner’s turbocharger systems are installed in all types of vehicles by car makers worldwide. With a wide range of different turbochargers and repair kits, the supplier offers tailored solutions for all customer requirements in the aftermarket, including classic turbochargers, turbochargers with variable turbine geometry for diesel and gasoline engines and regulated, multi-stage turbocharging systems for cars, light, and heavy commercial vehicles.

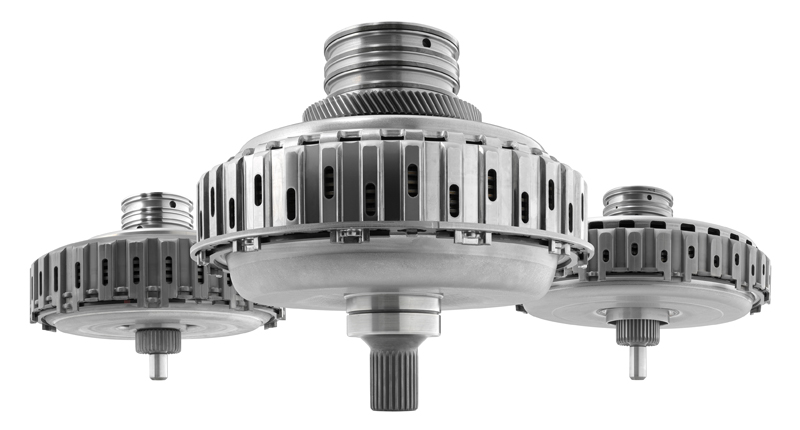

Already available for the aftermarket are BorgWarner’s dual-clutch modules with patented DualTronic technology. The supplier is the world’s leading provider of clutch components and systems for automatic transmissions, with millions of vehicles on the road equipped with them. BorgWarner offers six DualTronic modules for the most common vehicle types, which it also supplies to automakers. Their advantages: They operate extremely efficiently, provide smooth shifting, meet OE requirements and, according to the manufacturer, guarantee perfect fitment. This opens up promising market opportunities for trade and workshops.

Cost-efficient alternative

Through its REMAN program, BorgWarner offers aftermarket partners remanufactured components that are meticulously cleaned and thoroughly tested for reliability according to high OE quality standards. In the turbocharger sector, this includes 800 different remanufactured turbochargers for 5,000 different applications: for cars, commercial vehicles, as well as agricultural and construction machinery. In exhaust gas recirculation, workshops can choose from a broad portfolio of remanufactured EGR valves.

As a cost-efficient alternative to new spare parts, remanufactured parts will always be a popular choice, especially for older vehicles. With recycled components, workshops have a solution for quality- and cost-conscious customers. Additionally, remanufacturing is a significant contribution to environmental protection. More than five million turbine, bearing, and compressor housings have been reused in the REMAN program, saving thousands of tons of aluminum and tens of thousands of tons of cast iron.

With a steadily growing portfolio, BorgWarner offers the aftermarket over 10,000 products. Aftermarket products and components are marketed in new, uniform packaging. The sustainably produced boxes feature the renewed, dynamic company logo and clearly indicate the contents. Their blue colouring ensures high recognition value.