BorgWarner developed the world’s first high-volume series production dual clutch module for automatic transmissions, helping to deliver the fuel economy of a single clutch transmission, with gearshift quality to rival the best conventional automatic transmissions.

Within the automobile industry, a continual goal is to improve the efficiency of the powertrain. This not only makes a valuable contribution toward reducing fuel consumption and emissions, but can also improve vehicle dynamics and enhance the driving experience. Reducing energy losses during manual gearshifts is one solution, which can be achieved by automating the clutch operating and gear shifting processes that would normally be performed by the driver. In an automatic manual transmission, sensors convey relevant information to an electronic control unit, which uses the data to calculate the optimal shift points. Electromechanical or hydraulic actuators then carry out the clutch and shift actions with minimal interruption of torque.

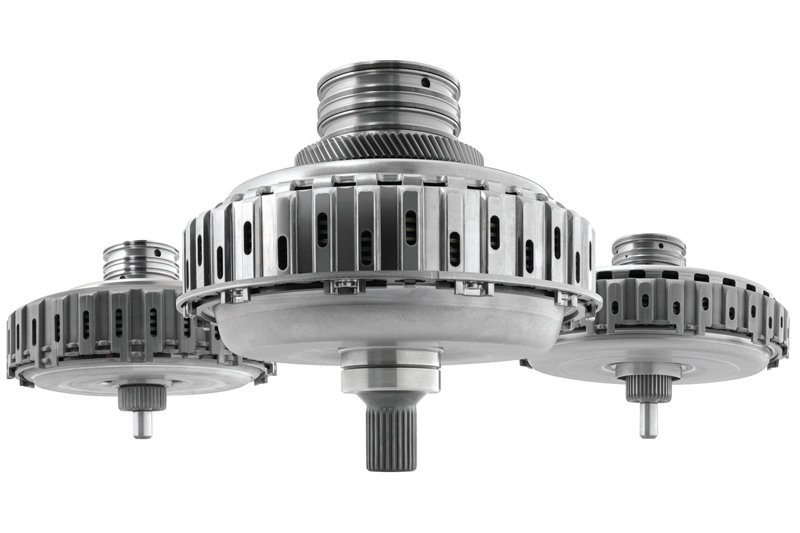

How a dual clutch automatic transmission works

The internal layout of a typical dual clutch automatic transmission resembles two manual gearboxes within a single casing, each requiring a clutch. One clutch serves a defined set of gears via a solid input shaft, while the other clutch serves the remaining gears via a second, concentric hollow input shaft. By using separate input shafts, two gears can be engaged simultaneously. Engine output is coupled via one clutch to one part of the gearbox, while the next gear is preselected in the other part of the gearbox. During a gearshift, one clutch opens and the other closes within milliseconds, allowing an imperceptible change of gear ratio under load, without interrupting torque or traction.

BorgWarner developed the world’s first high-volume series production dual clutch module for automatic manual transmissions – the DualTronic clutch system – and today produces almost one million units annually. Electronic control of the clutches and gearshift means that launch and shift characteristics are tunable by managing the shift points and shift speed, catering for driving styles from relaxed to sporty, different weather/road conditions, or special situations such as towing a trailer. A DualTronic-equipped transmission delivers fuel economy that rivals single clutch automatic gearboxes; it also provides shift quality matching that of the best conventional automatic transmissions, but in a package that is lighter and more compact.

Design characteristics

The DualTronic clutch plates are composed of high energy wet composite friction materials. Compared to a dry clutch system, durability and reliability are improved, and the higher slip energy capacity enables a smooth and rapid launch from rest, as well as superior hill-hold and creep performance. Over its lifetime, the wet clutch maintains more stable friction and damping characteristics with reduced fluctuation in operating temperatures. The clutch package is of modular construction: by varying the number and size of the friction plates, it can be optimised for either a short axial dimension or minimal radial dimension according to the platform architecture. It can also be configured to handle engine torque of up to 1,500 Nm or input speed in excess of 9,000 rpm, to support the widest range of vehicle applications in the segment. Actuation can be achieved by oil feed-through or concentric slave cylinder with thrust/release bearing.

A BorgWarner DualTronic-equipped transmission aims to offer the comfort and convenience of an automatic transmission, plus the enhanced dynamic response of a manual gearbox for extremely fast gearshifts with no interruption of power delivery and improved acceleration. DualTronic clutch technology also aims to improve powertrain efficiency to support a reduction in CO2 emissions.