Valeo outlines the challenges facing batteries and alternators in modern passenger vehicles and what the company is doing to meet those needs.

As vehicles are becoming increasingly complex and additional safety and comfort systems are constantly added, the strain on the conventional 12 V battery is increasing dramatically. Vehicle manufacturers are constantly looking for solutions to provide the necessary electrical output whilst also looking at reducing CO2 emissions.

Since the 2000s, the output of alternators has been increased by 40 per cent. At that point the average alternator had the ability to produce 105 amps with the highest performing alternators delivering approximately 140 amps. Today, the global average output is at 145 amps and vehicle manufacturers demanding alternators that can deliver up to 300 amps.

Boosting comfort

Alternators have always been the heart of vehicle electric systems and throughout the years manufacturers have demanded more refinement to meet their requirements whether it be to reduce noise levels, to make the vehicle more comfortable to drive, or to reduce losses of power so that fuel economy and electrical efficiency is maximised. It is constantly evolving.

Valeo is constantly exploring new ways of meeting manufacturer’s requirements. Whether it is the invention of the stop/start system or the introduction of the 48 V Integrated Belt Starter Generator (iBSG), we are constantly looking for solutions that will help with emissions reduction whilst still providing the vehicle with the electricity it requires.

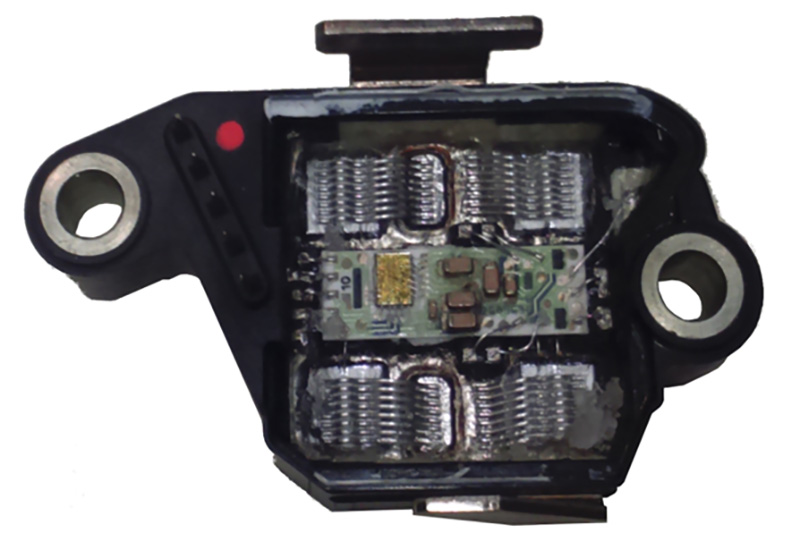

In 2014, Valeo introduced the efficient generation alternator to reduce the amount of voltage drop or losses within the system. Standard alternators contain a rectifier and it is the job of the rectifier to convert the alternating current into direct current. This process is known as rectification. It allows the positive voltage to pass onto the Bat+ terminal and onto the battery, while allowing negative voltage to pass to the ground. The rectifier is a bridge made up of a series of diodes. Diodes serve as one way check valves that allow current to flow in only one direction. Most alternators have three or six diodes. If one of these fail, it will reduce alternator output by approximately one third.

The efficient generation alternator, whose current rectifying, from alternative into direct current for the network, is no longer produced by standard diodes but with a power electronic component: The MOSFET bridge.

The MOSFET bridge utilises Metal Oxide Semiconductor Field Effect Transistors instead of diodes. Thanks to their micro‐electronic structure, MOSFETs are able to almost eliminate the voltage drop during current rectifying – instead of 1.0 V it is at < 0.2 V.

Given that Power = Voltage x Current, power losses inside the bridge are divided by the factor of five. Already implemented on StARS (stop-start technology), this technology has the following advantages:

- Reduces voltage drops by factor of five versus diodes

- It generates less heat

- Gains in amps at idle RPM

- Gains in efficiency by eight points

- CO2 reduction of about 2 g/km

Thanks to higher efficiency, the alternator takes less power from the crankshaft to generate a certain amount of electricity. This saving can be converted into fuel and finally into CO2. The European Commission awarded the EG High Efficiency Alternator as an Eco Innovation. It is the second Eco Innovation recognition and the first ever given to a system supplier.

Efficiency drive

As we move forward into the electrification revolution, the efficient generation alternator has once again been adapted. The latest adaption of this technology is within the Valeo 48 V system. This system allows manufacturers flexibility when producing mild hybrid vehicles.

Valeo’s 48 V system is the result of a better trade-off between price and performance, making hybrid technology affordable for everyone. It is suitable for all types of vehicle, particularly entry-level vehicles. The 48 V system combines a conventional combustion engine with a low-power electric machine, generating up to 15% reductions in fuel consumption and halving the cost per gram of CO2 saved compared to a hybrid on the market today. And, 48 V doesn’t impact engine architecture – the combustion engine is the same, only adding a 48 V IBSG and a DC/DC converter. 48 V is also safe for humans. The voltage is classed as non-dangerous so no additional qualification is needed to work on this technology/system.

The standard components of the 48 V iBSG (based on the efficient generation alternator) which can be incorporated into the position of a standard alternator due to the dimensions being very similar, is a DC/DC converter, which is able to step voltage down to 12 V to feed the 12 V network or to step 12 V up to 48 V to pre-charge the iBSG for start-up. And a 48 V battery pack, both of which are small enough to fit under seats or boot compartments.

With the 48 V iBSG, this not only works as an alternator producing alternating current, it is also capable of restarting the vehicle in stop/start scenarios as well as additional support for the engine when required – whether that be boosting the engine when pulling away or under load or keeping the vehicle at a steady speed whilst coasting. All these benefits contribute towards lowering the strain on the combustion engine and therefore reduce CO2 emissions and improve the fuel economy.

Reducing engine load further

The 48 V system can be adapted even further by adding components that would normally be driven by the vehicles auxiliary belt, such as the air conditioning compressor and power steering pump and electrify them using the 48 V system to run them. This in turn again is reducing the load on the engine and improving our fuel economy and reducing emissions.

So to summarise, the constant evolution of the alternator, which was once a critical but simple component within a vehicle, has now evolved to be a pivotal part of affordable hybridisation for manufacturers. As with all components within a vehicle there are always ways to improve and the alternator evolution will continue.