AS-PL investigates some common issues surrounding starters.

The starter does not stop turning

The most common starters used in vehicles with internal combustion engines are electric starters. These can be otherwise known as DC motors, which turn the crankshaft of the engine and give it enough speed to start running on its own. The starter draws most of its electricity from the battery when the engine starts.

The starter can suffer from various faults, which can be electrical or mechanical in nature.

Electrical causes

One of them may be the starter not responding when you turn the key to idle. It continues to work while it should stop. This could be:

- Defective ignition switch or electronic system switching on the starter (in the case of cars, in which we do not need the key to start), that is the final power stage (relay or transistor keying this relay). The solution to this problem should be sought in the electrical starting system. If we have eliminated the failure of the ignition switch, then further diagnostics will be necessary

- A starter (solenoid switch contacts) that has become stuck/short. The solution to this problem is to buy a new one. If the bendix has taken on the colour of black burnt steel, it also indicates damage and should be replaced

If we have eliminated the causes of electrical failures, we should look at the mechanical side of these components as well.

Mechanical causes

Mechanical causes of continued starter operation include:

A damaged bendix pinion, especially if it will jam into the flywheel pinion.

A damaged and worn solenoid switch in the bushing or in the fork, which can be caused by contamination with dust or thickened old grease. In this case, the electromagnetic switch must be cleaned or replaced with a new one.

A damaged flywheel rim pinion that is sticking in the bendix pinion or the sum of the damage to both.

Damage to the pinions does not always cause the starter to run continuously. Sometimes it can also come to a delayed disconnection. Nevertheless, if you notice any problems with the starter, it is worth conducting a detailed diagnostic investigation. It may be necessary to replace the flywheel rim or even the bendix.

Starter rotates the engine crankshaft too slowly

The crankshaft is an element of the piston engine that converts the sliding motion of the piston and the connecting rod into a rotary motion. It consists of journals (main and crankpin) shifted in relation to its axis, shaft arms with counterweights, a flywheel disc and a crank arm that connects the pins.

The shape of the shaft depends, among others, on the number and arrangement of cylinders in the engine, the engine design, firing sequence, number of main shaft journals, etc. The crankshaft is forged mostly from higher-quality, non-alloyed steel. Cast shafts are used less frequently. In order to ensure its proper hardness, the surface hardening or carburising (for shafts made of alloy steel) is used.

Most engines have a crankshaft bearing at every cylinder, which increases the stiffness of this system. There is usually a flange at the rear of the crankshaft for mounting the flywheel, and the timing drive is usually at the front.

A starter starts an internal combustion engine and the most common starters used are electric starters, which are DC motors. They rotate the engine crankshaft and give it the proper speed that allows the engine to start running independently on its own.

Analysing failures

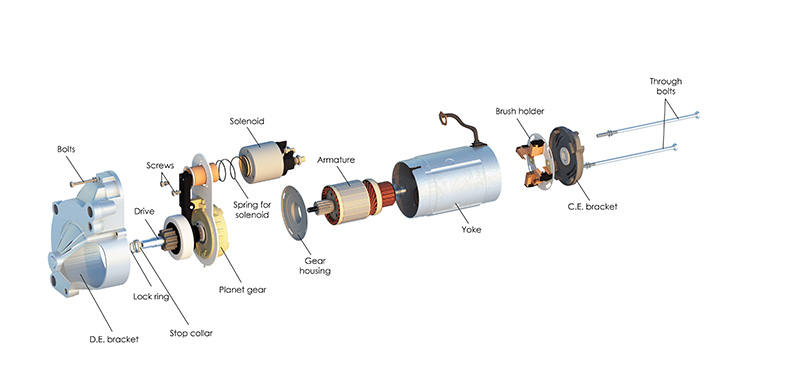

The electric starter of an internal combustion engine draws most of its electrical energy from the battery when starting the engine. The starter consists of, among other parts, the head, the bendix (including the protection base), the gearbox, the automaton and its spring, the rotor, the stator, the brush-stopper and the rear cover.

If we were to rule out engine damage as the cause of the starter turning the crankshaft by the starter, we can go into an analysis of the potential causes of this situation.

The cause of the failure could be the sliding bushings that have worn out. It could also be “play” that develops between the axle and bushing and causes the rotor transformer plates to rub against the magnetic/electromagnetic stator.

The rotor, to which current is applied through a commutator, acts as an electromagnet, which attracts more than it rotates.

In turn, the higher flow-through current, flowing through the brushes can cause more wear on these components.

The starter must be replaced for the vehicle to operate properly. As an alternative to costly replacement with a new model, a remanufacturing of the worn-out product may prove to be an option. In this case, such a regeneration consists of replacing the bushings, brushes/brush tops. However, it is worth approaching the reconditioning comprehensively and examining all working elements.