UFI Filters has expanded its range of cabin filters.

UFI Filters presents a completed range of cabin air filters, whose main function is to protect against dust, soot, bacteria, pollen and other pollutants that may enter the vehicle interior. The entry of these pollutants can, in extreme cases, turn the entire passenger compartment into a comfortable breeding ground for pathogens. This is why it is essential to choose a quality cabin filter and replace it on a regular basis.

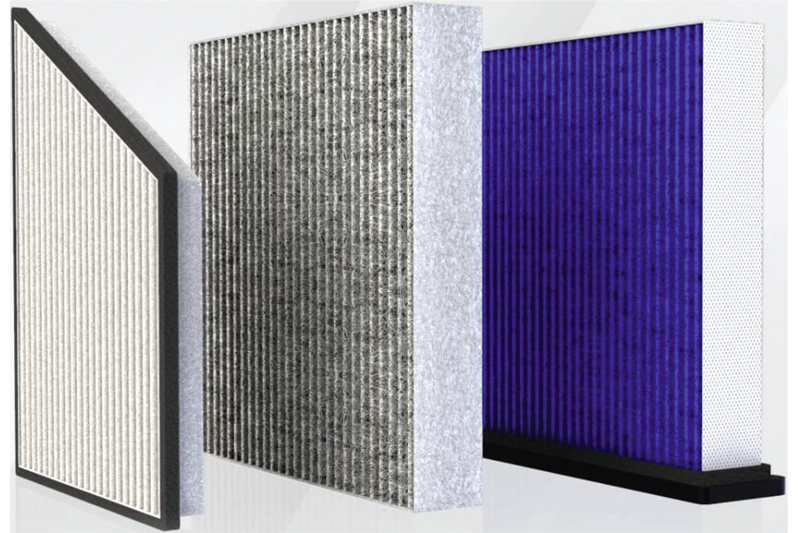

Using its experience in research and development of new materials, the company has developed different types of FormulaUFI.Stratiflex filter media for cabin filters, which claim to guarantee high filtering efficiency, resistance to moisture and microbiological neutralisation. This is why the UFI Group can offer three types of cabin air filters in its aftermarket catalogue: from the traditional pollen filter to the activated carbon filter, which is also capable of blocking unpleasant odours, to the antibacterial filter of its Argentium range.

The brand’s catalogue now offers over 700 references of cabin filters, 607 for cars and commercial vehicles and 111 for on-road and off-road trucks, covering over 19,000 applications. This range has grown significantly over the recent years, ensuring that more than 98.5 per cent of all vehicles on Europe’s roads are covered by UFI Filters.

There are 363 pollen filters made with synthetic non-woven filter media, capable of retaining over 90 per cent of particles with a diameter greater than 2.5 μm, such as PM10 fine dust, dirt and pollen. UFI pollen filters can be identified in the catalogue by the initial code 53.

196 carbon filters, on the other hand, are the references consisting of non-woven filter material combined with activated carbon, which also absorbs gases and odours, and blocks industrial and agricultural pollutants such as hazardous NOX, SO2, NH3 and VOC. UFI carbon filters ensure greater protection inside the vehicle and can be identified in the catalogue by the initial code 54.

Argentium filters

UFI Filters’ 159 UFI Argentium filters are equipped with antibacterial properties. The filter media consists of three layers: structural, absorbent and antimicrobial, incorporating silver particles. Biomaster biocide silver, tested to ISO 22196:2011, can inhibit bacterial growth by up to 99 per cent. Argentium UFI filters can be identified in the catalogue by the initial code 34.

The concentration of dust in the atmosphere and the presence of different types of harmful particles, such as PM10 and PM2.5, depends on weather conditions and the geographical area. Their presence can be up to six times higher inside the vehicle, due to the ‘tunnel effect’ created through the ventilation circuit. The direct consequences of poor air quality while driving include: allergies, sore throats, sneezing, lack of attention at the wheel to reduced visibility caused by condensation on the windscreen and windows.

After autumn and winter have left their mark on the vehicle’s cabin air filter with moisture, dust, fine dust and debris, it is important to replace it for spring. The company recommends changing the cabin filter regularly every 15,000 km, and at shorter intervals in particularly dusty areas, or every 6-12 months at the latest.

Heat exchangers specified for Renault and Nissan

UFI Filters is not only involved in filtration, but also in thermal management, and the company is now supplying original equipment heat exchangers for Renault-Nissan-Mitsubishi Alliance’s electric motors.

The firm has been chosen to supply the heat exchanger for the new ePT-160 front electric motor, 160kW, mounted on the new Renault Megane E-Tech and Nissan Ariya. The e-motor will also equip other C-segment model vehicles that will be launched by 2024 within the Franco Japanese alliance and has the potential to become very popular in Europe in the next few years.

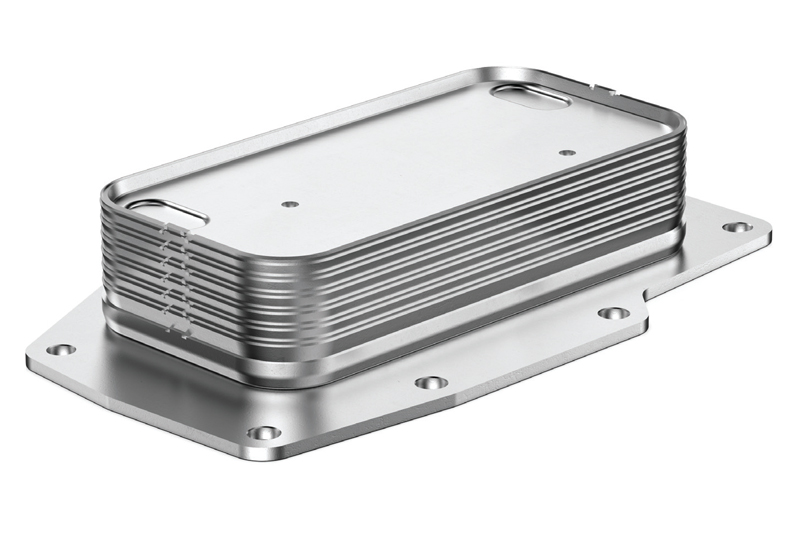

The heat exchanger for the ePT-160 is of an aluminum plate type and produced according to vacuum brazing technology that allows for a very robust and clean product. The UFI heat exchanger is made up of four layers dedicated to oil and four to coolant. The oil enters through the base plate fixed directly on the outside of the electric motor. The heat exchanger configuration is diagonal counter-flows. It means that the liquids (oil and coolant) flow in opposite directions, oil and coolants cross their path into alternating layers.

For the 4×4 version available on Nissan Ariya e-4ORCE 4WD, it supplies an additional heat exchanger for the rear electric motor. Also made of aluminum and featuring vacuum brazing technology, it has seven layers for oil and six for coolant. The oil and coolant liquid enter through the base plate fixed directly on the outside of the electric motor. The heat exchanger configuration is parallel counter-flows. The two liquids flow in opposite directions but remaining on the same side of the plates layer.

With these two applications, UFI Filters is strengthening its position as leader in electric motor thermal management.